Assistance device for transient acceleration and deceleration phases

A technology for turbine engines and generators, which is applied to the ignition of jet propulsion devices, gas turbine devices, turbine/propulsion devices, etc., can solve problems such as the limitation of surge margins in the acceleration performance of turbine engines, and achieve the goal of reducing speed and size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

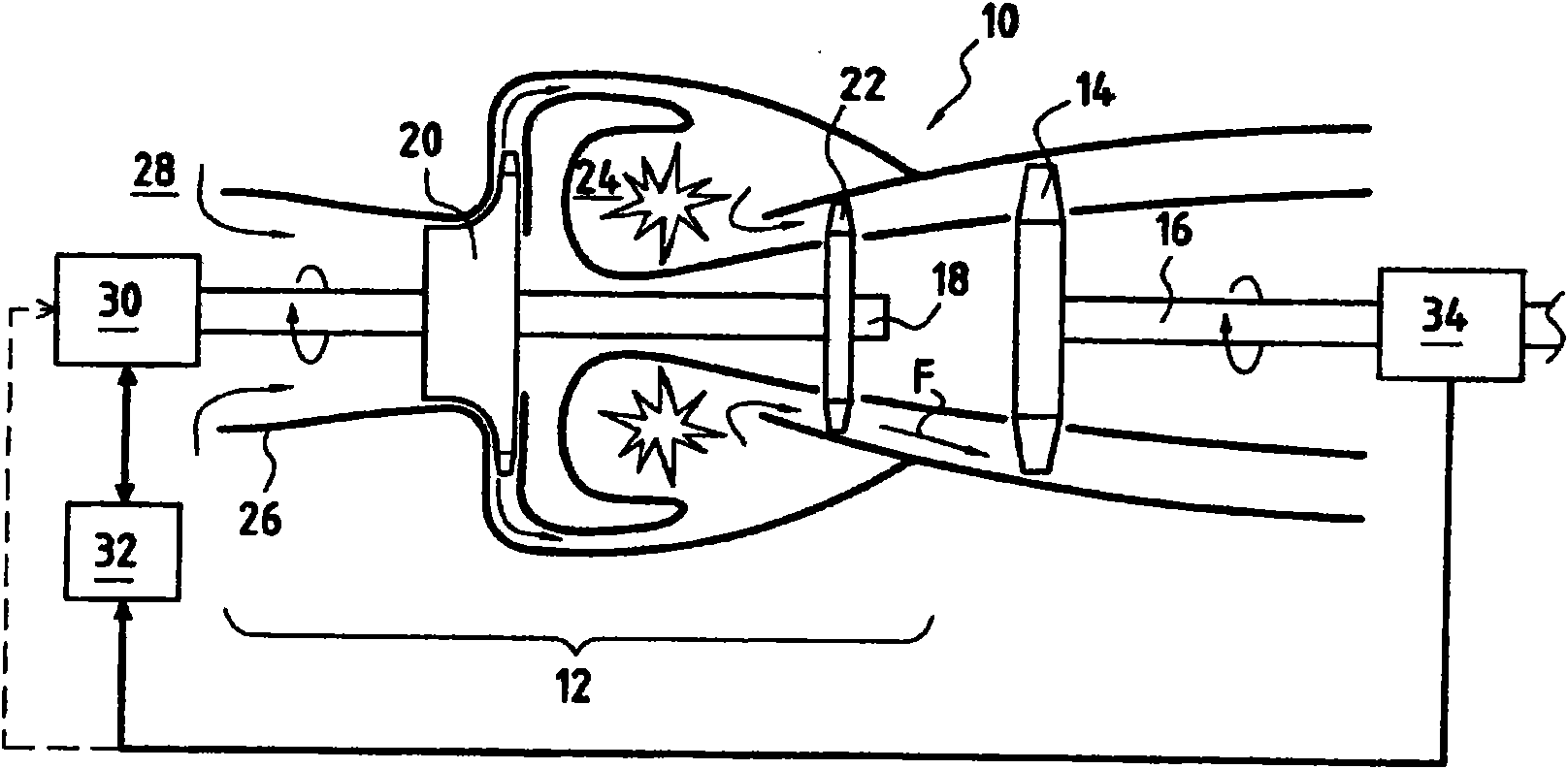

[0055] figure 1 is a view showing a turbine engine 10 constituting a first embodiment of the present invention and used in particular to drive a helicopter rotor (not shown) in rotation, the turbine engine 10 including a gas generator 12 and a free turbine 14 capable of receiving gas The air flow F generated by the generator 12 is driven to rotate.

[0056] The free turbine 14 is mounted on a shaft 16 which transmits the rotational motion to a receiving unit, for example the main rotor of a helicopter.

[0057] like figure 1 The illustrated turbine engine 10 is of the rear output type. Turbine engines with a front-exit free turbine shifted by an external shaft or with a front-exit free turbine shifted by a coaxial shaft are conceivable without departing from the scope of the invention.

[0058] The gas generator comprises a rotating shaft 18 on which a centrifugal compressor 20, a turbine 22 are mounted and axially arranged between the compressor 20 and the turbine 22 when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com