Method of continuous annealing for steel strip with curie point and continuous annealing apparatus therefor

A technology of annealing equipment and Curie point, applied in the field of continuous annealing equipment, can solve the problems of poor strip dispersion, poor uniformity of decarburization, lack of disclosure and teaching, etc., and achieve the effect of high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

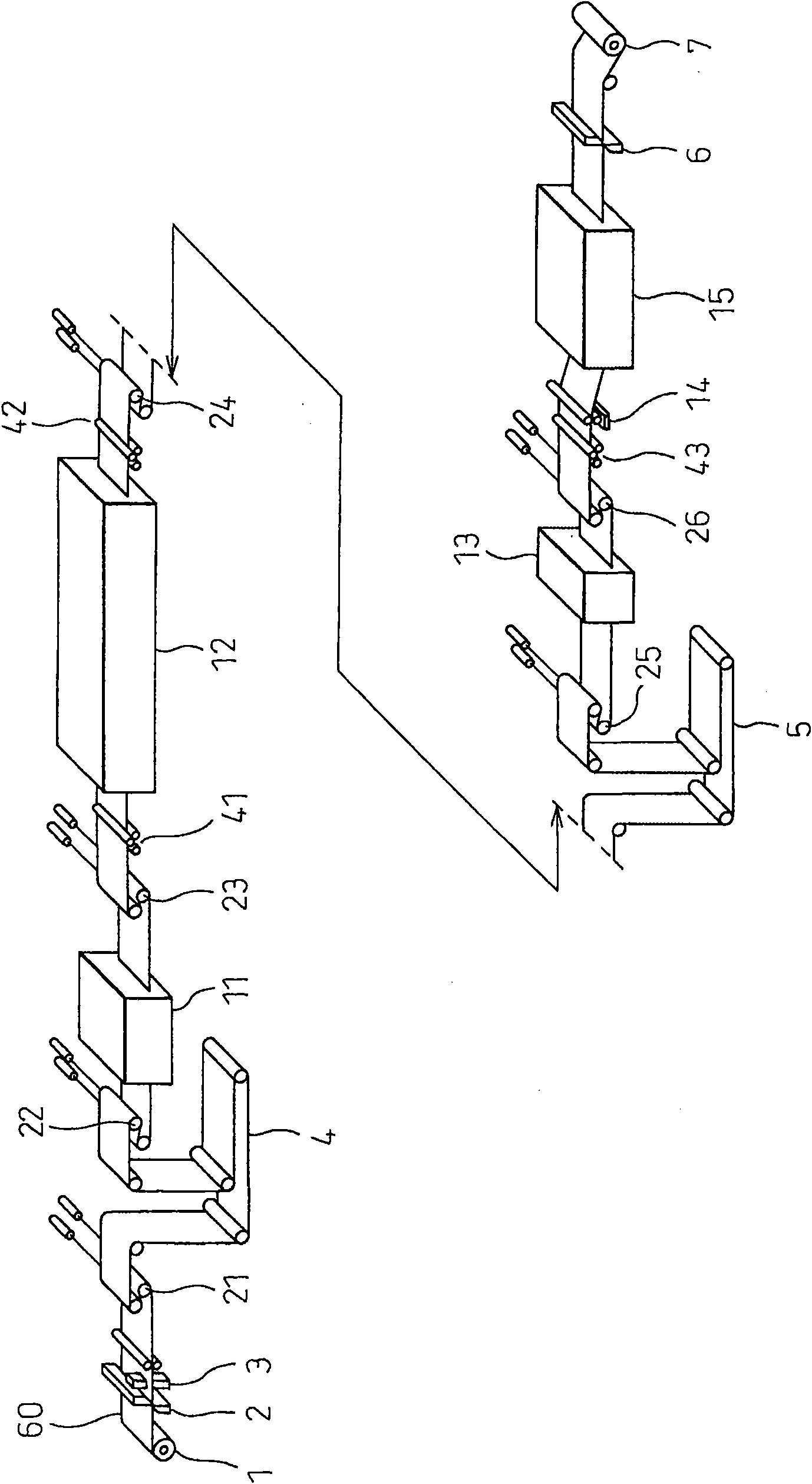

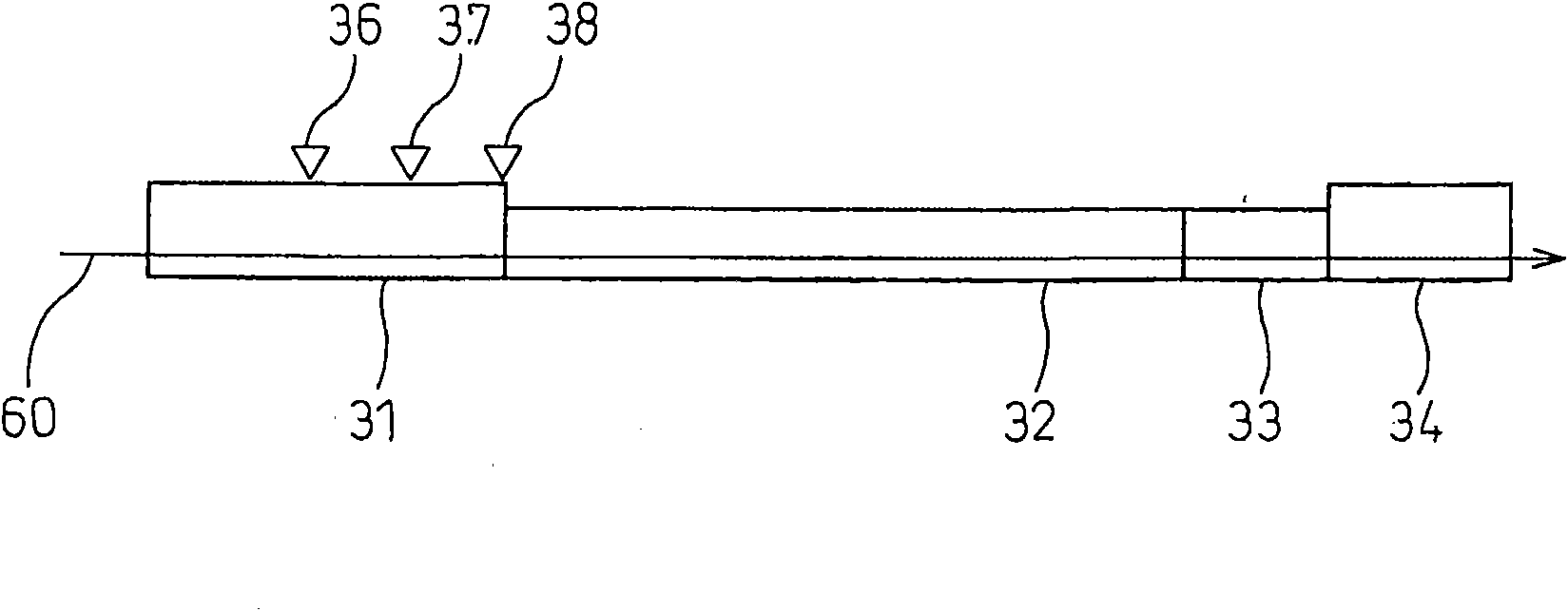

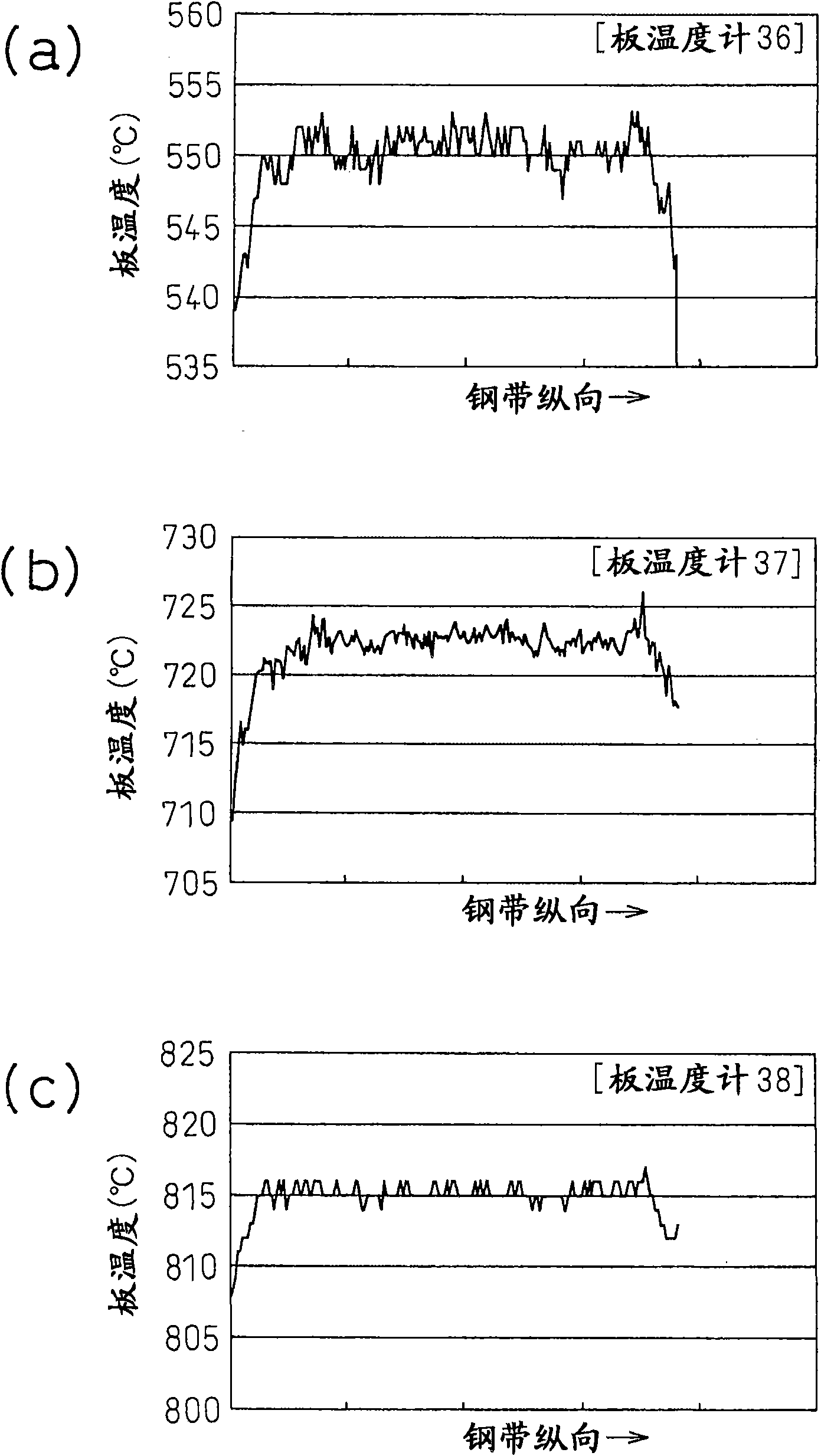

Embodiment 1

[0113] A steel plate containing C: 0.06%, Si: 3.3%, Mn: 0.1%, P: 0.03%, S: 0.008%, acid-soluble Al: 0.028%, N: 0.008%, and Cr: 0.1% in mass % After the billet was heated at 1150°C, it was hot-rolled to a thickness of 2.3mm to form a steel strip coil, and then two-stage annealing was performed at annealing temperatures of 1120°C and 920°C. And then, after cold rolling to plate thickness 0.22mm with reversing rolling mill, adopt the decarburization annealing equipment of prior art ( figure 1 , figure 2 ) and decarburization annealing equipment of the present invention ( figure 1 , Figure 4 ) for decarburization annealing. Thereafter, after high-temperature annealing, smoothing annealing is finally performed. At this time, the temperature of the steel sheet on the exit side of the heating zone of the furnace part 12 was measured by the sheet thermometer 38, and at the same time, the film defect rate of the grain-oriented electrical steel sheet after smoothing annealing was ...

Embodiment 2

[0119] A slab containing C: 0.005%, Si: 0.1%, Mn: 0.1%, Cr: 15%, P: 0.02%, S: 0.01%, and N: 0.01% in mass % is placed at a temperature of 1200°C After heating, it was hot-rolled to a plate thickness of 5 mm to form a coil, and then annealed at 900° C. was given. And then, after cold rolling to plate thickness 2mm with reversing rolling mill, utilize the mode of prior art in annealing equipment ( Figure 6 , Figure 7 ) and the mode of the present invention ( Figure 6 , Figure 8 ), bright annealed at 950°C. At this time, the hardness of the obtained ferritic stainless steel plate after bright annealing was measured, and the defect rate of strength was measured while measuring the temperature of the steel plate on the exit side of the heating zone of the furnace portion 12 with the plate thermometer 58 . The test conditions and results are shown in Table 2 (target values A and B are the same as in Table 1).

[0120] In Examples 21 and 22 of the present invention, there ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com