Demagnetization method of large-scale ferromagnetic pipe fitting and magnetic-sensitive sensor

A degaussing method and ferromagnetic technology, applied in the field of magnetic sensitive sensors, can solve the problems of pipe fitting adsorption, strengthening of residual magnetic field, and affecting the precision machining of pipe fittings and the welding of pipe fittings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

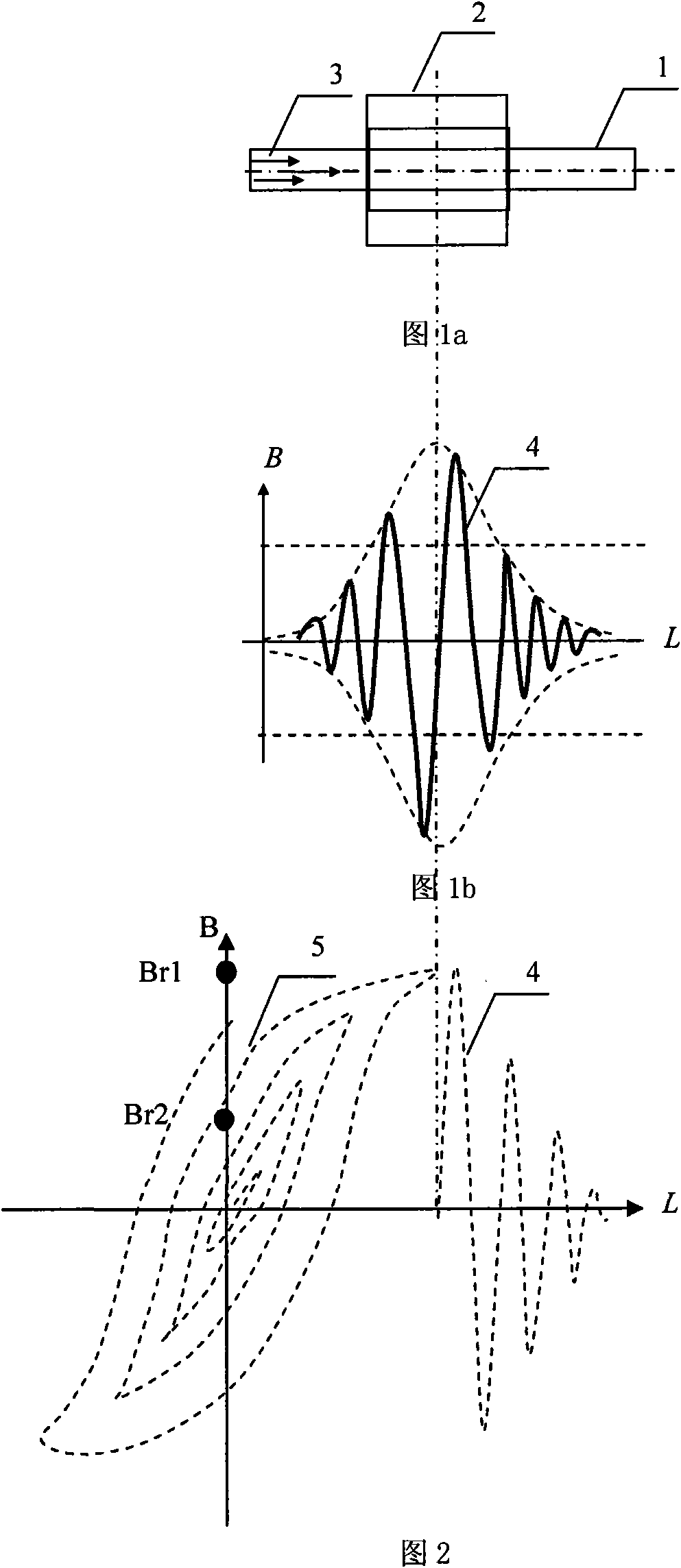

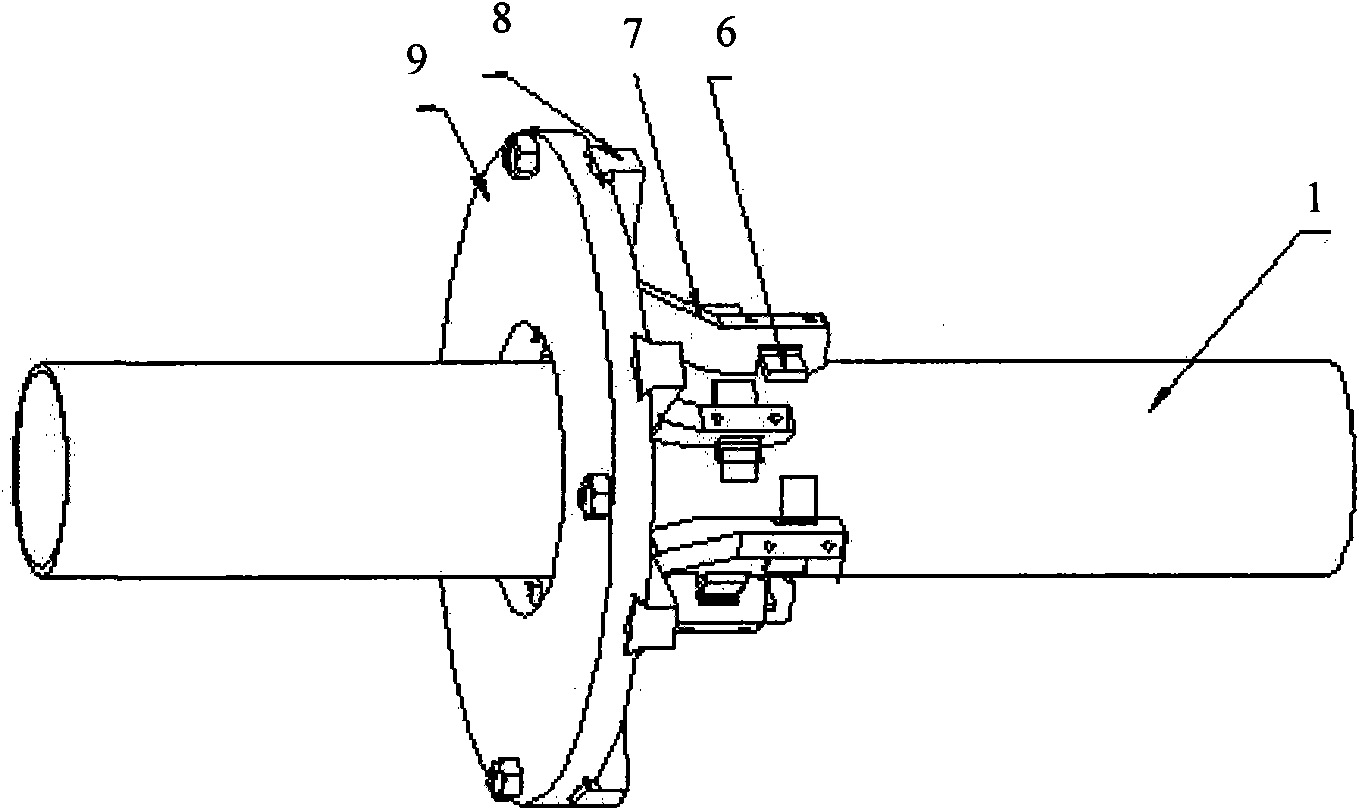

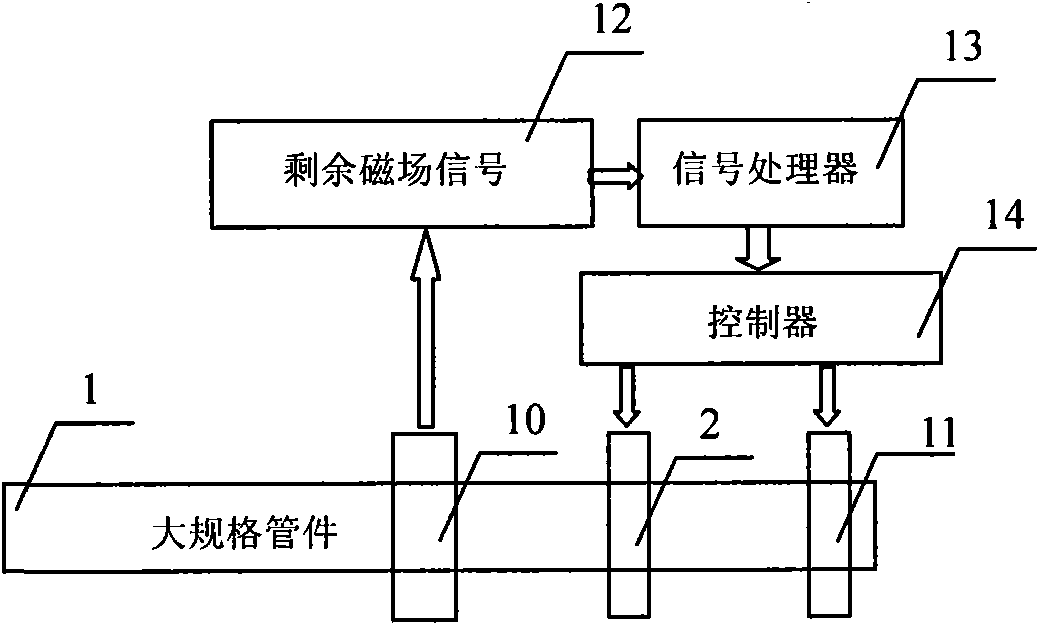

[0036] for Figure 1a The large-scale ferromagnetic pipe fitting 1 shown is affected by the axial DC magnetic field, forming a residual magnetic field 3 in the pipe fitting body, especially forming an anisotropic residual magnetic field above 500GS at both ends. Figure 4 In the degaussing method for large-scale pipe fittings shown, the residual magnetic field signals 12 such as the direction, pitch and intensity of the axial residual magnetic field of the pipe fittings are first detected by the magnetic sensor array 10. Since the pipe fitting 1 only has an axial DC residual magnetic field, the passing signal The processor 13 drives the controller 14 to feed the reverse degausser 2 to form a degaussing field opposite to the residual magnetic field, offset most of the residual magnetic field, and make the pipe end externally present a residual magnetism below 100GS; finally, a densely wound coil with alternating current is used 11. Demagnetize the pipe fitting 1 so that the res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com