Large power composite ultraphonic pipe

A composite ultrasonic and composite tube technology, which is applied in the directions of sound-producing instruments, instruments, chemical instruments and methods, etc., can solve the problems of limited total output power of cylindrical transducers, low vibration energy conversion efficiency, and round tubes should not be made too long. , to achieve the effect of significant internal heat generation, high electro-acoustic efficiency, and improved electromechanical conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

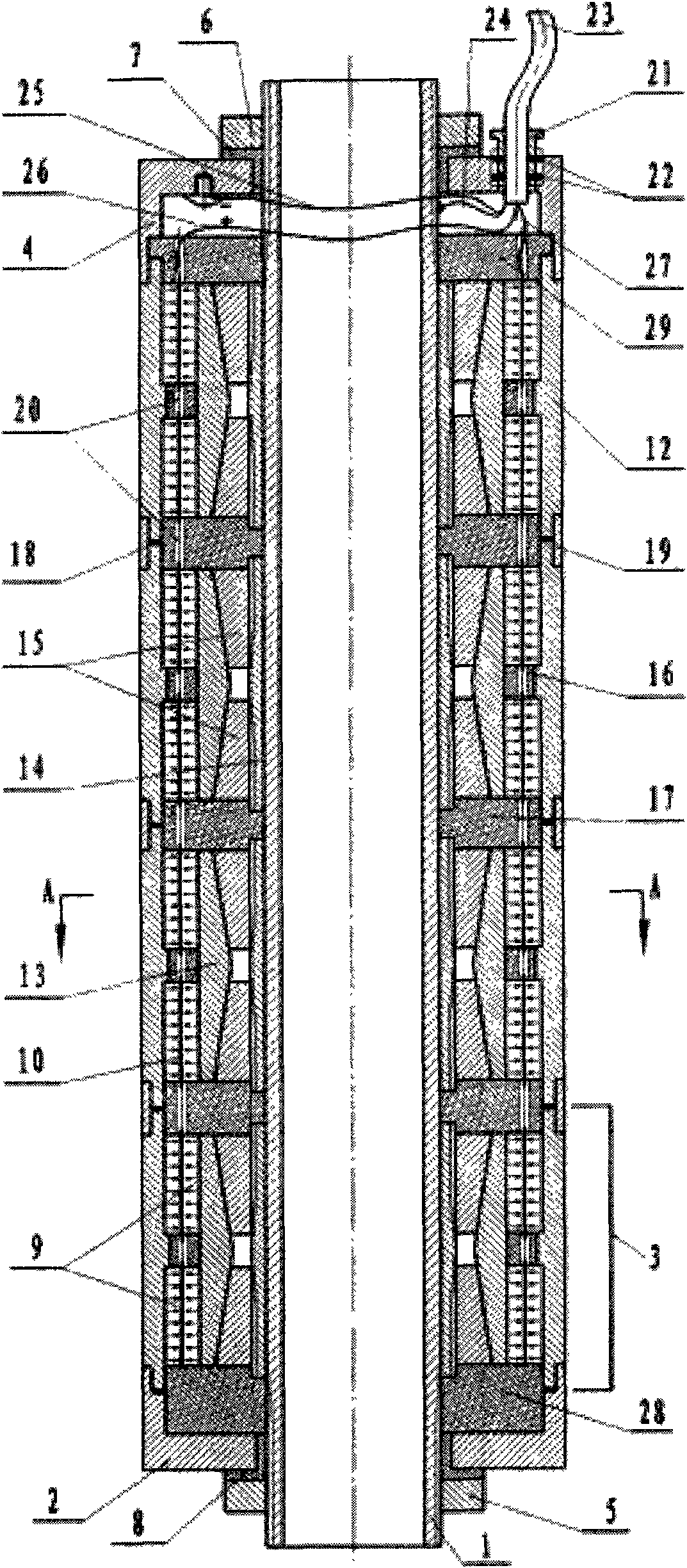

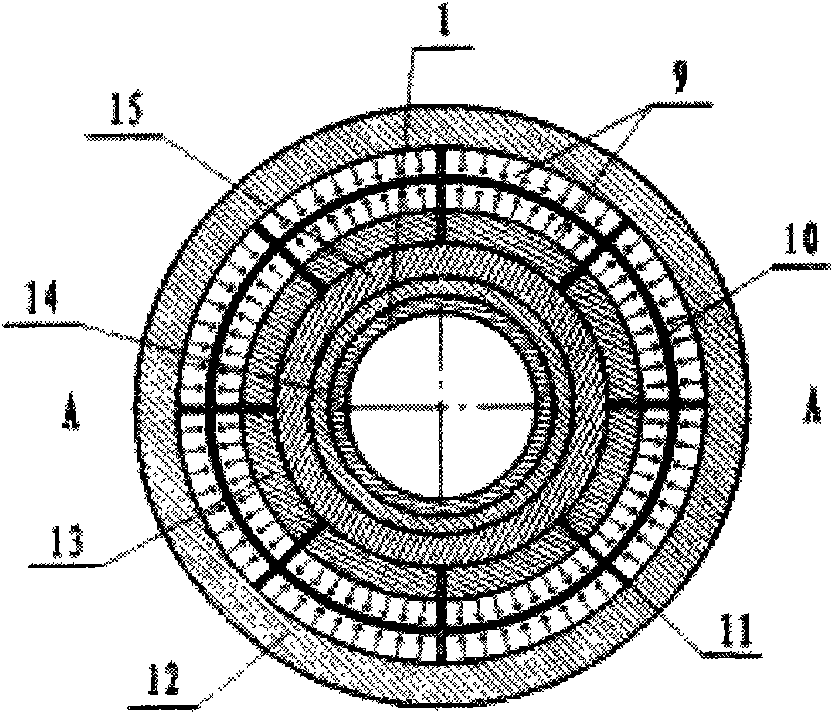

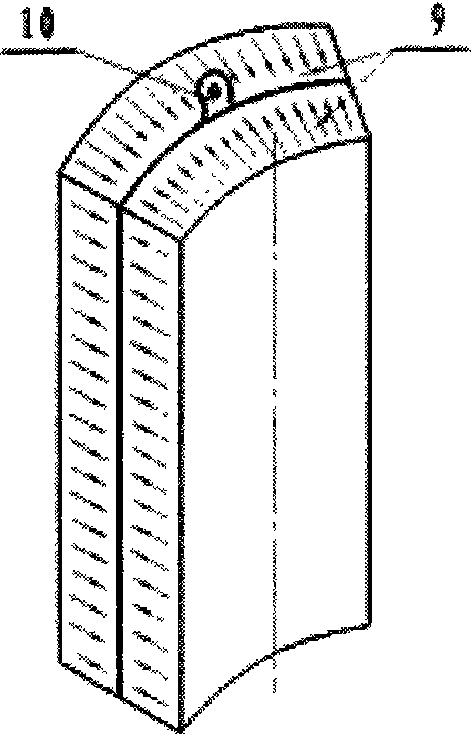

[0033] Such as figure 1 As shown, a high-power composite ultrasonic tube consists of a hollow threaded tube 1 passing through the end cap 2 with a central through hole and four short composite tube piezoelectric transducer units 3, and then passing through the central through hole of the end cap 4 , use nuts 5 and 6 to tighten the connection at both ends respectively. Waterproof sealing rings 7 and 8 are arranged between the central through holes of the end caps 2 and 4 and the hollow threaded pipe 1 and the nuts 5 and 6 . Each short composite tube piezoelectric transducer unit 3 contains two sets of cylindrical piezoelectric ceramic stack ring groups, such as figure 2 As shown: each group of cylindrical piezoelectric ceramic stack rings consists of eight cylindrical piezoelectric ceramic stack units uniformly arranged in a ring along the circumference, as shown in image 3 As shown: each cylindrical piezoelectric ceramic stack unit is stacked by two arc-shaped piezoelectri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com