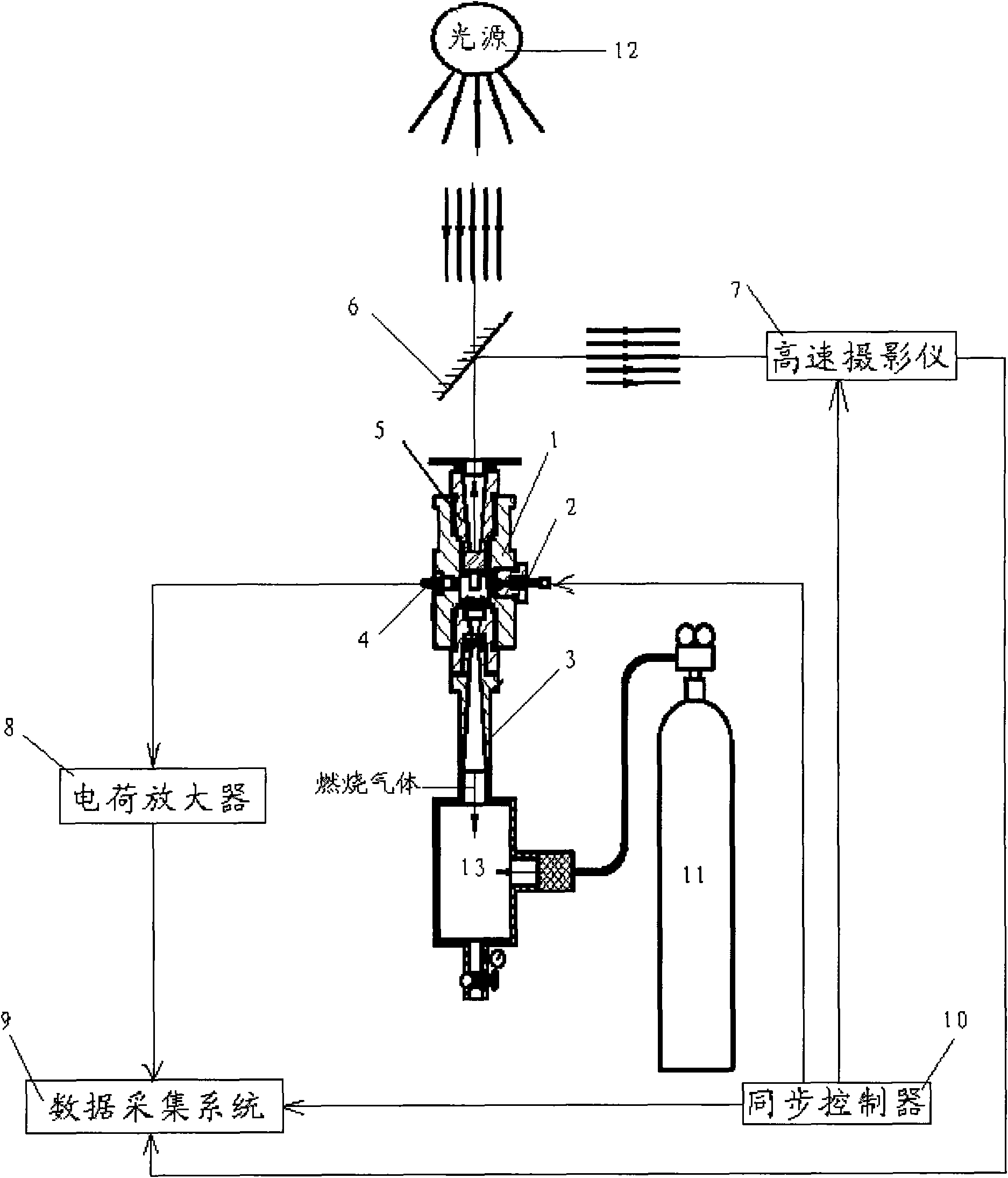

Gunpowder combustion property test device under pressure reduction condition

A technology of pressure drop and combustion characteristics, used in fuel testing, material inspection, etc., can solve the problems of less pressure points and narrow initial pressure range in the fire extinguishing environment of gunpowder, and achieve the effect of saving scientific research funds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

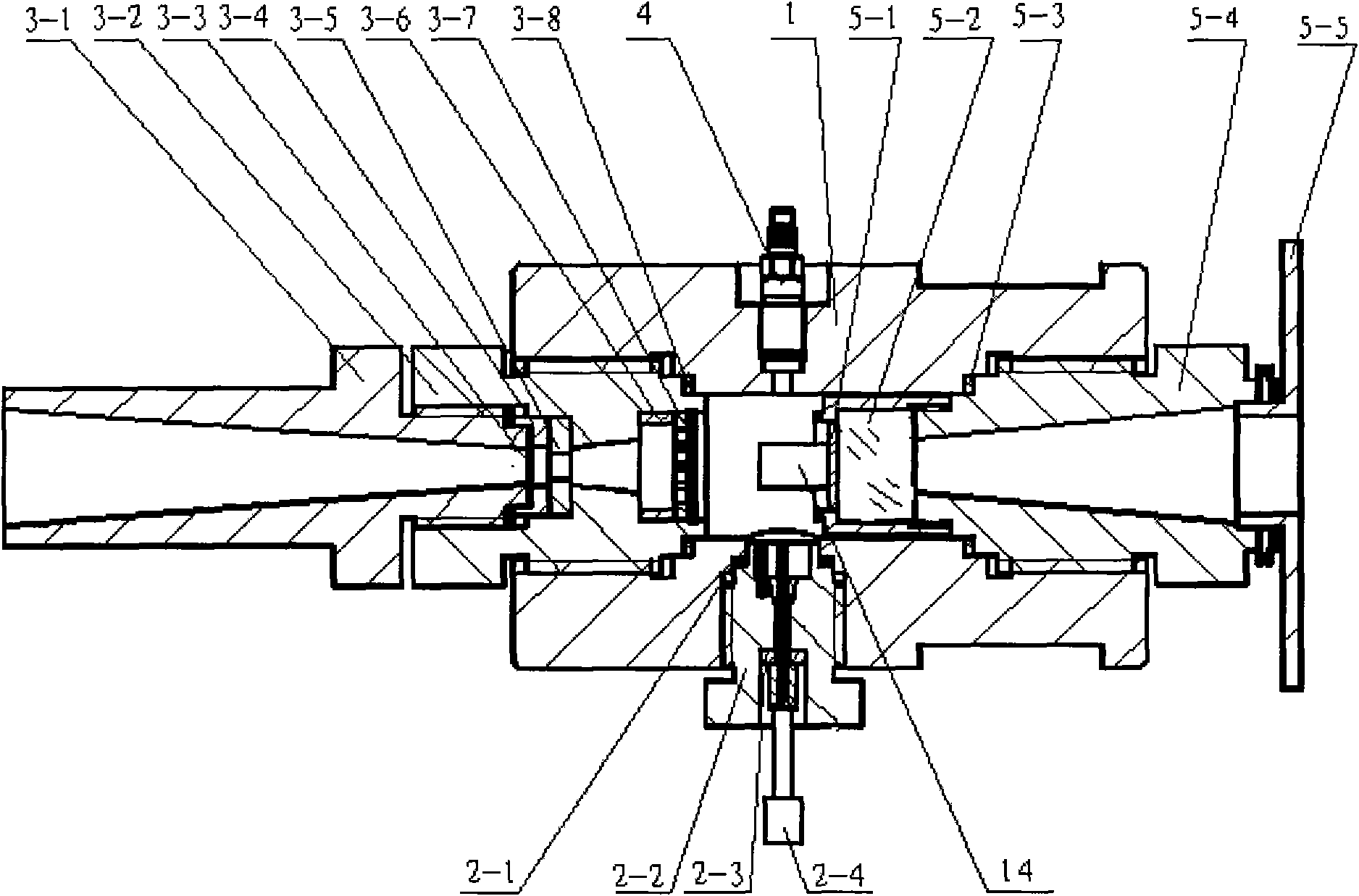

Method used

Image

Examples

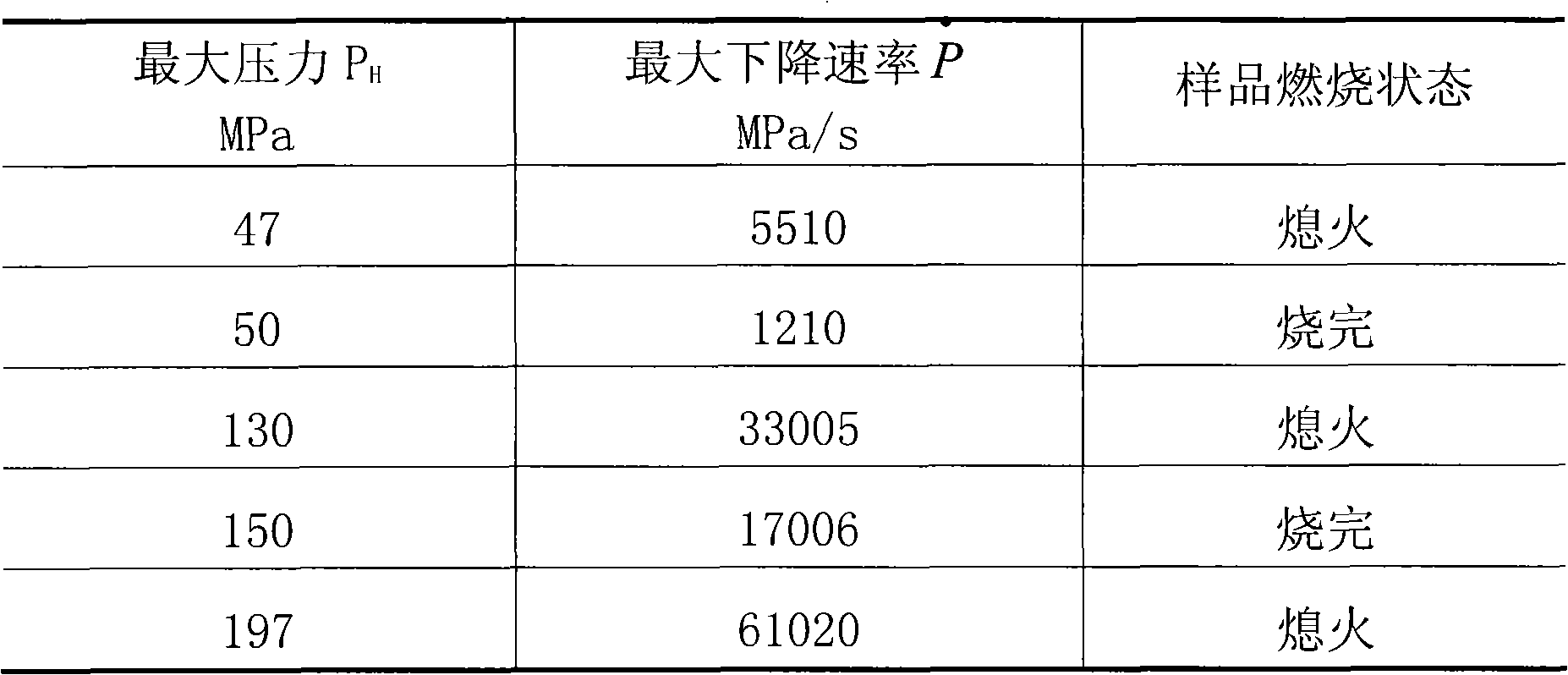

example 1

[0035] 实例1:在不同最大压力P H 及不同的最大下降速率 下,压力下降到P K =0.1MPa即1个大气压下,测试直径为7.5mm、长度为15mm的火药样品(硝化棉56%,硝化甘油28%,二硝基甲苯11%,其它5%)的燃烧状态示于表1。

[0036] Table 1

[0037]

example 2

[0038] 实例2:在不同最大压力P H (30MPa和100MPa)、不同最大下降速率 下,压力下降到P K >0.1MPa即大于1个大气压下,h=P K / P H =(0.08~0.5),测试直径为7.5mm、长度为15mm的火药样品(硝化棉56%,硝化甘油28%,二硝基甲苯11%,其它5%)的燃烧状态示于表2。

[0039] Table 2

[0040]

example 3

[0041] 实例3:一种直径为8mm、长度为15mm的双基药样品在不同压力下降速率下的燃烧速度及熄火时间如表3所示。

[0042] table 3

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com