Enhanced plastic double-walled corrugated pipe and manufacturing method thereof

A technology of double-wall corrugated pipe and manufacturing method, which is applied in the direction of hose, pipe, pipe/pipe joint/pipe fitting, etc., can solve the problem that the ring stiffness of pure plastic double-wall corrugated pipe cannot be made large, the diameter cannot be made large, and the ring stiffness Insufficient and other problems, to achieve the effect of high ring stiffness, high yield and smooth inner wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

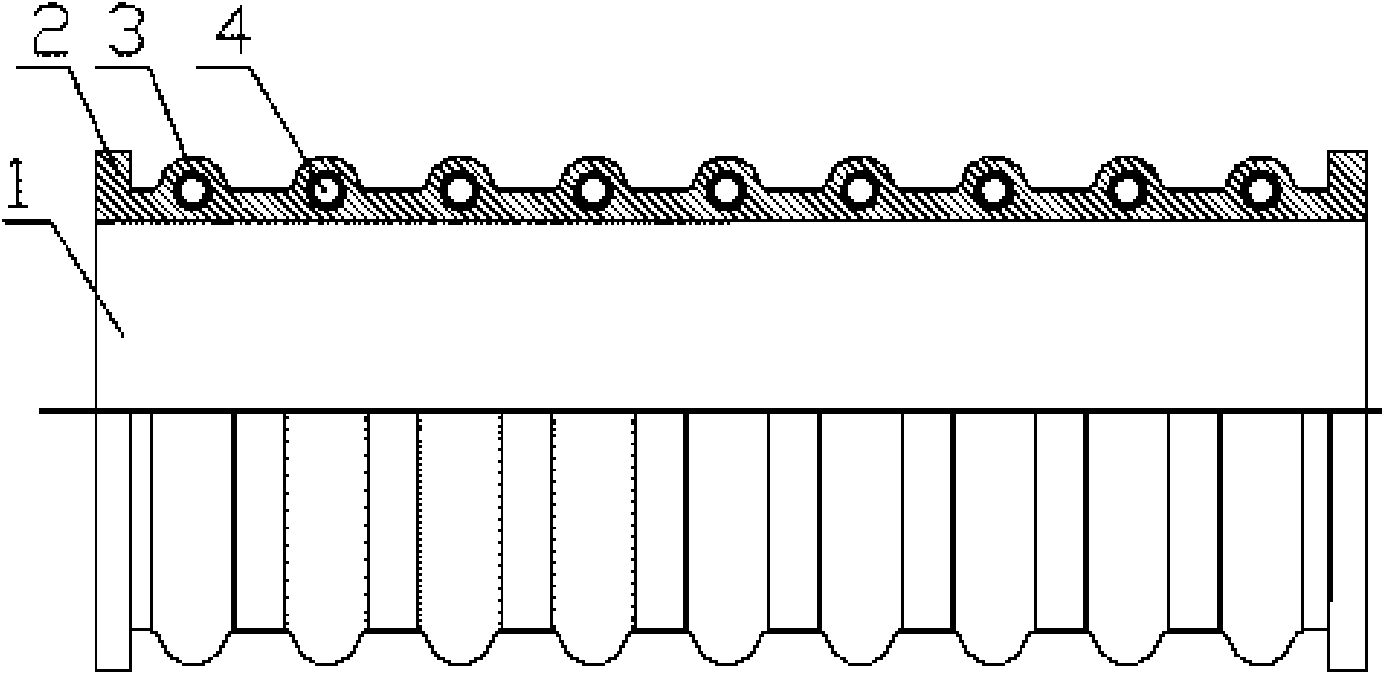

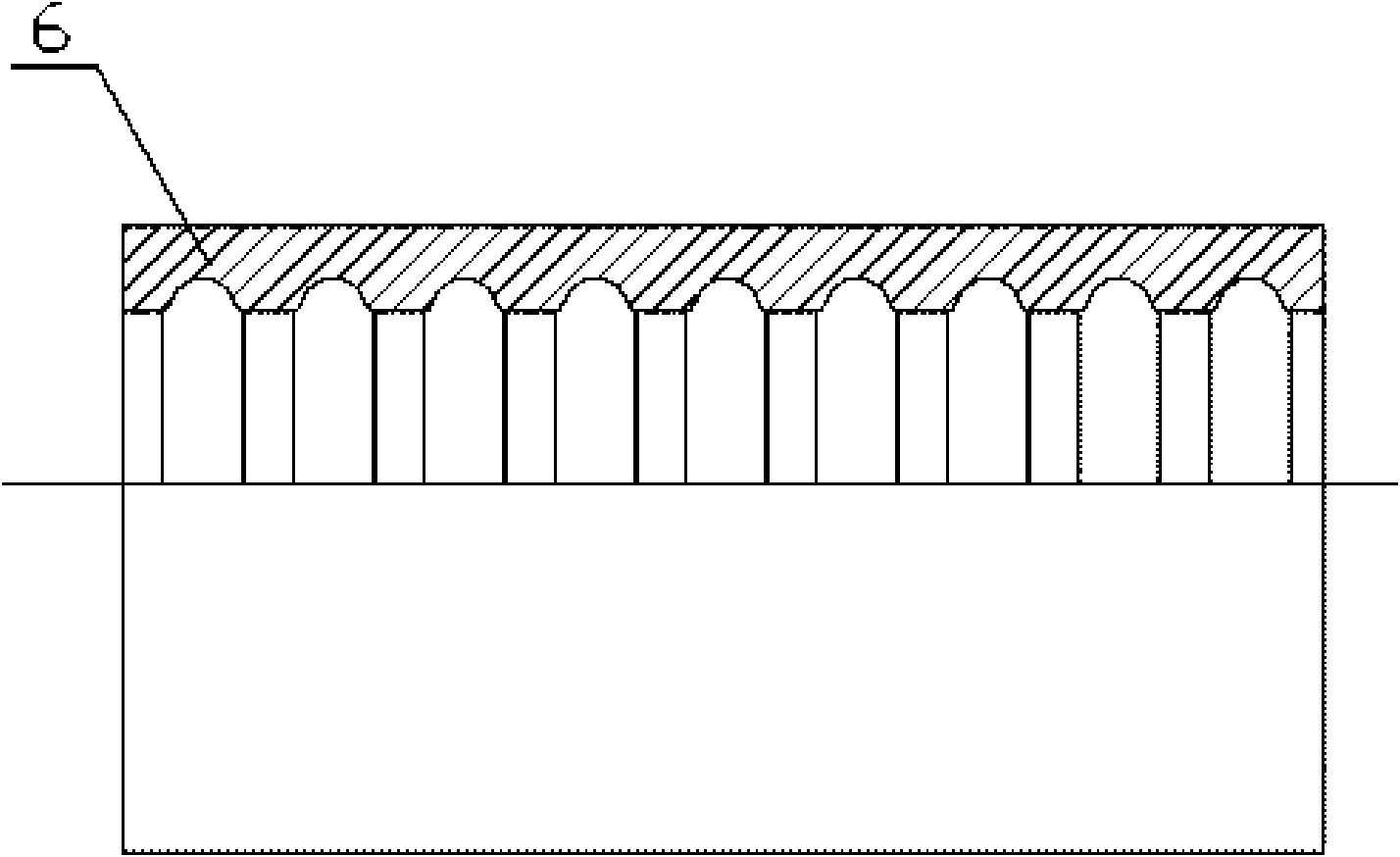

[0023] Specific embodiments of the present invention, such as figure 1 As shown, a reinforced plastic double-wall corrugated pipe 1 includes a pipe wall whose outer wall is a corrugated protrusion 3 , and a hollow inner pipe 4 is wrapped inside the corrugated protrusion 3 .

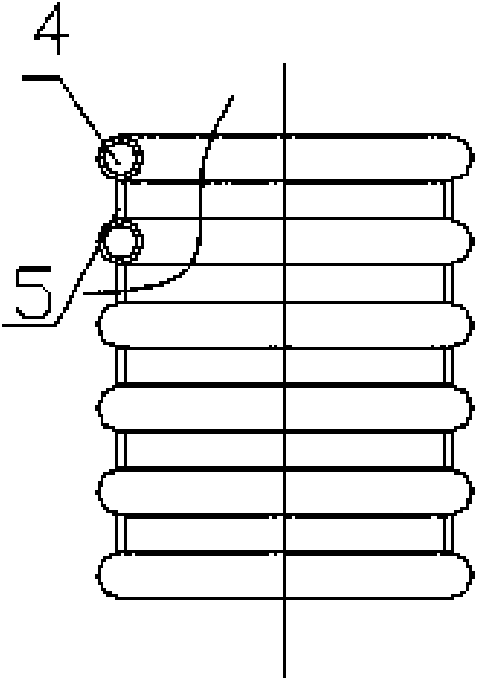

[0024] A preferred method of the above-mentioned inner pipe 4 is to use an annular hollow steel pipe. In order to facilitate the formation of the entire corrugated pipe, a support rod 5 can be connected between the steel pipe and the steel pipe. In order to facilitate the connection of the pipe ends during construction, integrally formed flanges 2 may be provided at both ends of the pipe, and at least one end of the flange has an annular groove for placing a sealing ring to seal the connection. The flange connection not only ensures the connection strength but also makes the connection process faster.

[0025] A reinforced plastic double-wall corrugated pipe and a manufacturing method thereof, comprising...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com