Water -emulsifiable nitrolacquer and preparation method thereof

A technology of nitro-lacquer and emulsifier, applied in the field of nitro-lacquer, which can solve problems such as unfavorable assembly line coating, packaging and shipment, and adhesion of nitro-lacquer, and achieve the effect of improving market application value, good environmental protection, and fast drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

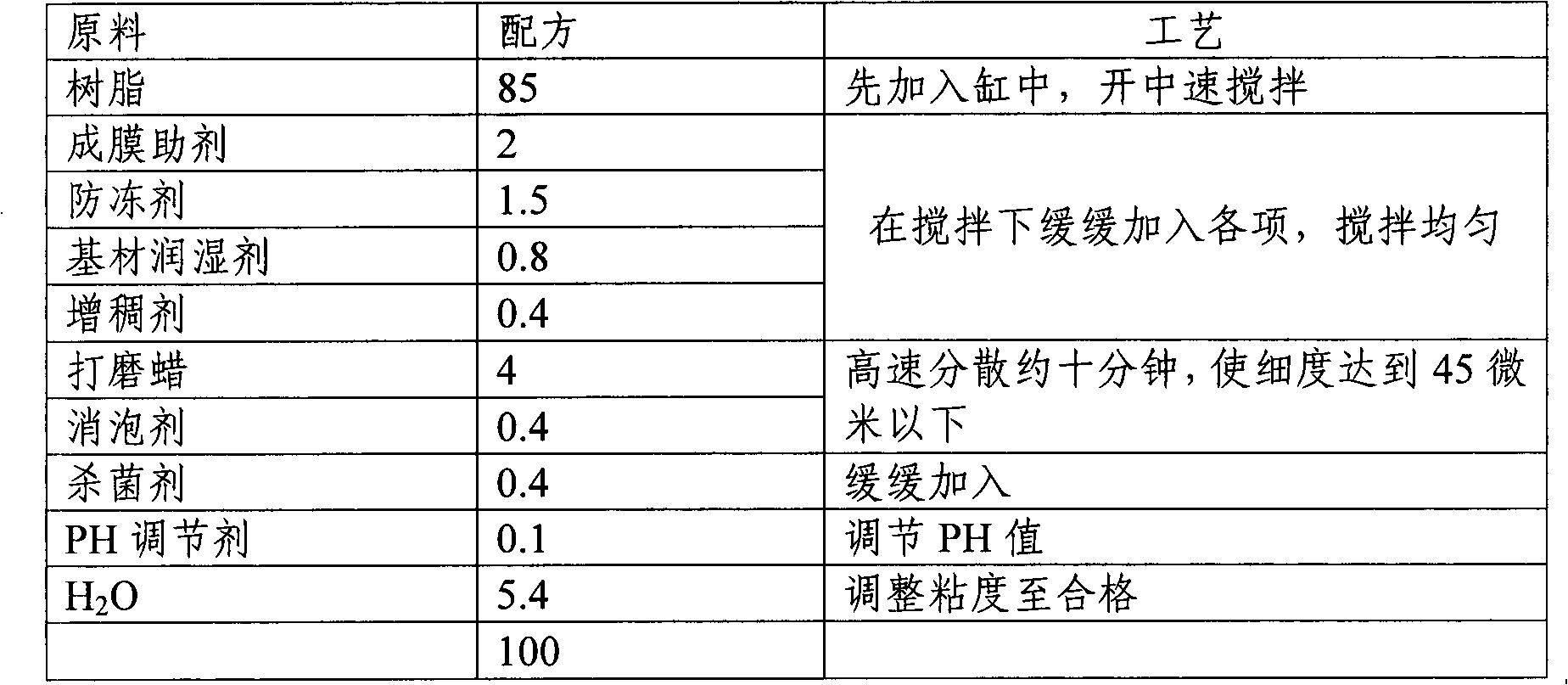

Image

Examples

Embodiment 1

[0036] Embodiment 1 The preparation of water-based nitro paint

[0037] 1. Main experimental raw materials

[0038] 1 / 4s nitrocellulose (70%): Luzhou North Chemical, 25kg;

[0039] Maleic acid resin: Shenzhen Jialicheng Chemical Co., Ltd., 14kg;

[0040] Dioctyl sebacate (DOS): molecular formula: C 26 h 50 o 4 , Zhejiang Tongxiang Chemical Industry, 11kg;

[0041] Emulsifier 1: Genapol x080 Clariant Chemical Emulsifier 2: SF8 Clariant Chemical;

[0042] Mixed solvent: 50kg, of which: butyl acetate 50%; BCS 15%;

[0043] PMA 35%.

[0044] Deionized water: homemade.

[0045] Coalescent: Dipropylene glycol butyl ether, Dow Chemical

[0046] Antifreeze: propylene glycol;

[0047] pH regulator: AMP-95, chemical name 2-amino-2-methyl-1-propanol, American ANGUS;

[0048] Polyurethane thickener【TT-935】: Rohm and Haas

[0049] Fungicide [LXE]: Rohm and Haas

[0050] Polishing wax [1097A]: Haichuan Chemical

[0051] Defoamer 【TEGO810】: Tego Chemical

[0052] Substrate wet...

Embodiment 2

[0072] 1. Main experimental raw materials

[0073] 1 / 4s nitrocellulose (70%): Luzhou North Chemical.

[0074] Maleic acid resin: Shenzhen Jialicheng Chemical Co., Ltd.

[0075] Dioctyl sebacate (DOS): molecular formula: C 26 h 50 o 4 , Zhejiang Tongxiang Chemical

[0076] Emulsifier 1: Genapol x080 Clariant Chemical Emulsifier 2: SF8 Clariant Chemical;

[0077] Mixed solvent:

[0078] Butyl acetate 50

[0079] BCS 15

[0080] PMA 35

[0081] Deionized water: homemade.

[0082] Coalescent: Dipropylene glycol butyl ether, Dow Chemical

[0083] Antifreeze: propylene glycol;

[0084] pH regulator: AMP-95, chemical name 2-amino-2-methyl-1-propanol, American ANGUS;

[0085] Polyurethane thickener【TT-935】: Rohm and Haas

[0086] Fungicide [LXE]: Rohm and Haas

[0087] Polishing wax [1097A]: Haichuan Chemical

[0088] Defoamer 【TEGO810】: Tego Chemical

[0089] Substrate wetting agent [BYK346]: German BYK company

[0090] 2. Preparation of water-based nitro resin:

[...

Embodiment 3

[0110] 1. Main experimental raw materials

[0111] 1 / 4s nitrocellulose (70%): Luzhou North Chemical.

[0112] Maleic acid resin: Shenzhen Jialicheng Chemical Co., Ltd.

[0113] Dioctyl sebacate (DOS): Molecular formula: C26H50O4, Zhejiang Tongxiang Chemical Industry

[0114] Emulsifier 1: Genapol x080 Clariant Chemical Emulsifier 2: SF8 Clariant Chemical;

[0115] Mixed solvent:

[0116] Butyl acetate 50

[0117] BCS 15

[0118] PMA 35

[0119] Deionized water: homemade.

[0120] Coalescent: Dipropylene glycol butyl ether, Dow Chemical

[0121] Antifreeze: propylene glycol;

[0122] pH regulator: AMP-95, chemical name 2-amino-2-methyl-1-propanol, American ANGUS;

[0123] Polyurethane thickener【TT-935】: Rohm and Haas

[0124] Fungicide [LXE]: Rohm and Haas

[0125] Polishing wax [1097A]: Haichuan Chemical

[0126] Defoamer 【TEGO810】: Tego Chemical

[0127] Substrate wetting agent [BYK346]: German BYK company

[0128] 2. Preparation of water-based nitro resin:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com