Motor and electronic apparatus having the same

A motor and rotor technology, which is applied in the field of motors, can solve the problems of reduced accuracy of speed detection and reading, and achieve the effect of reducing the number of assembly processes and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

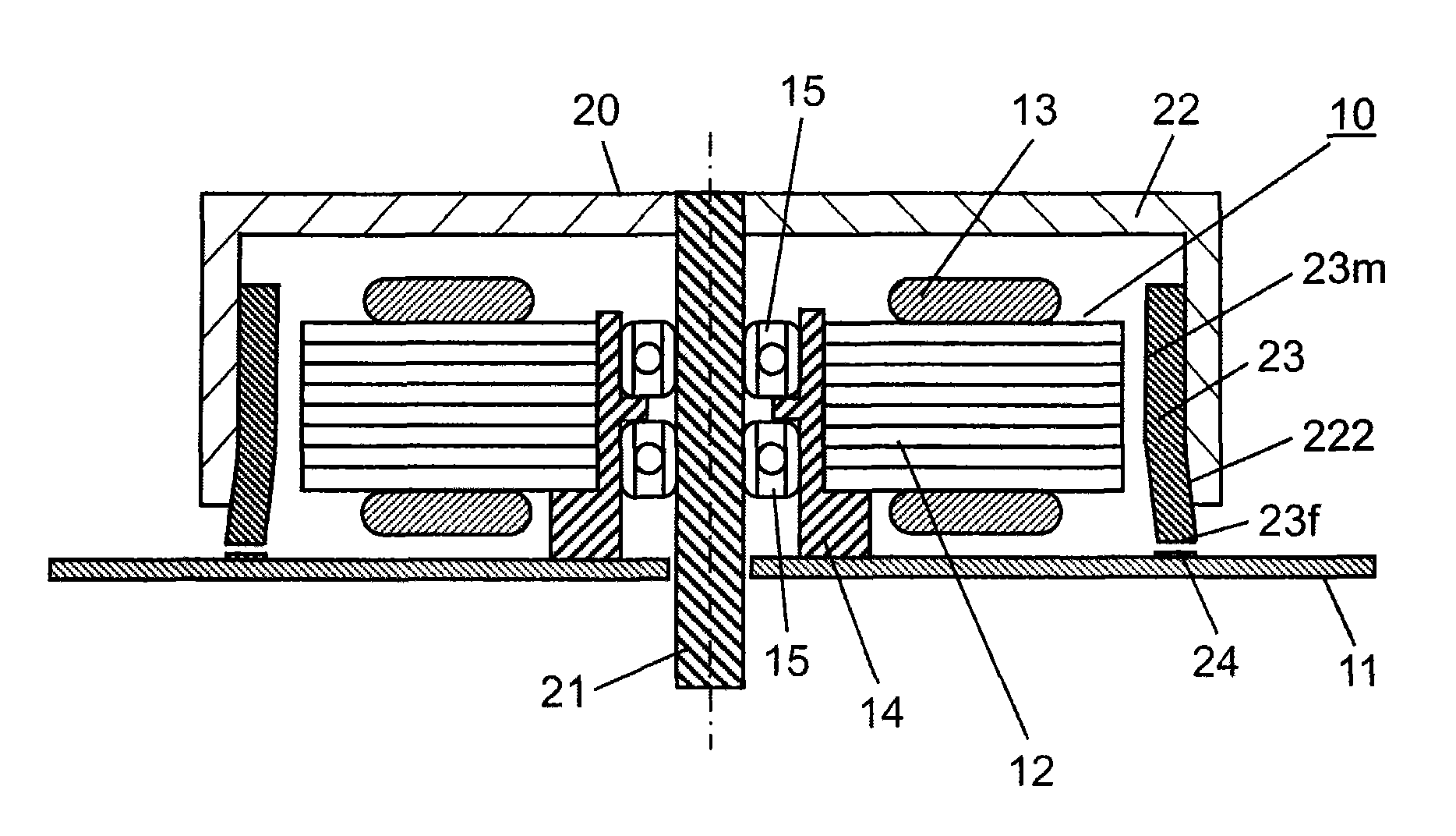

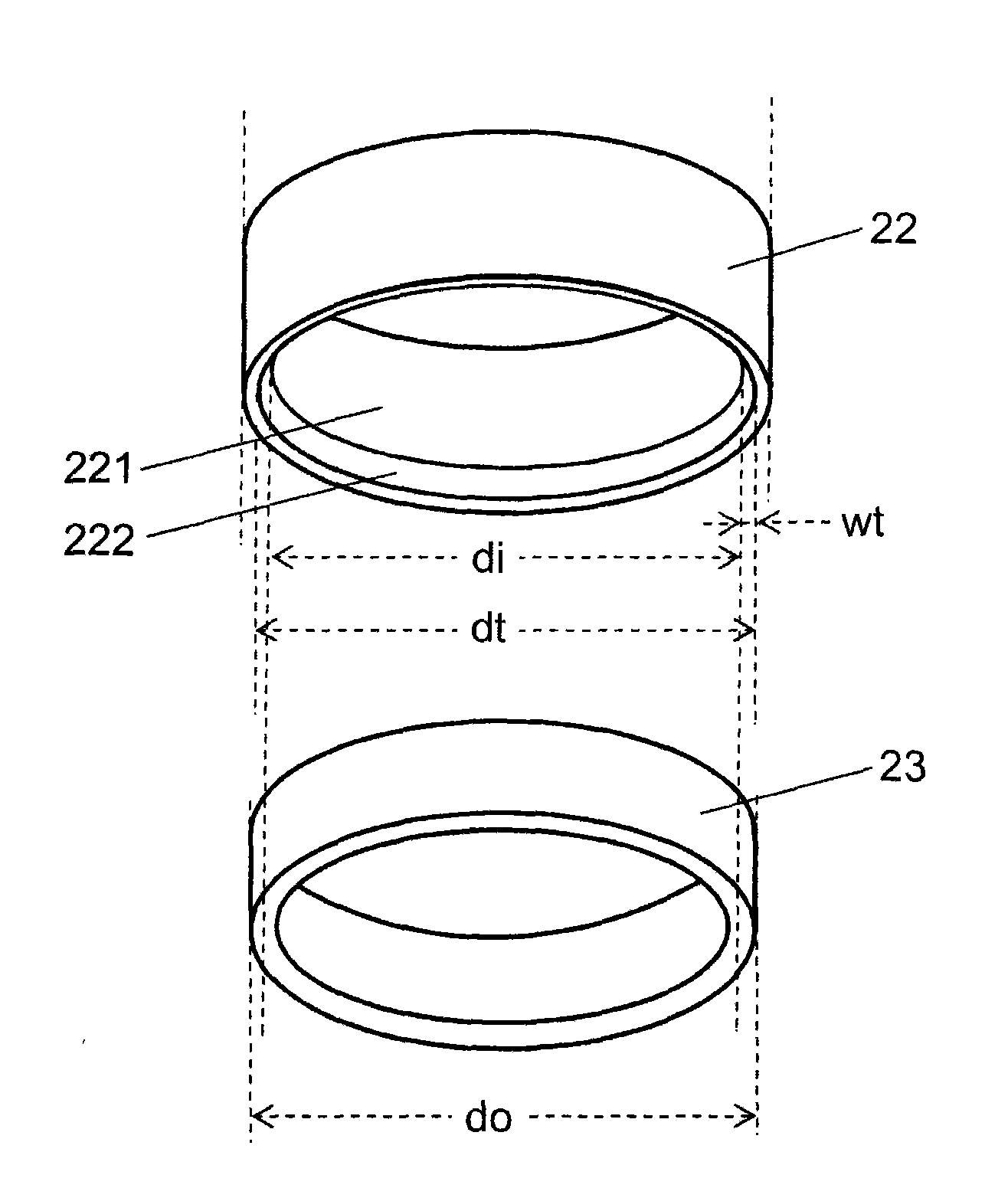

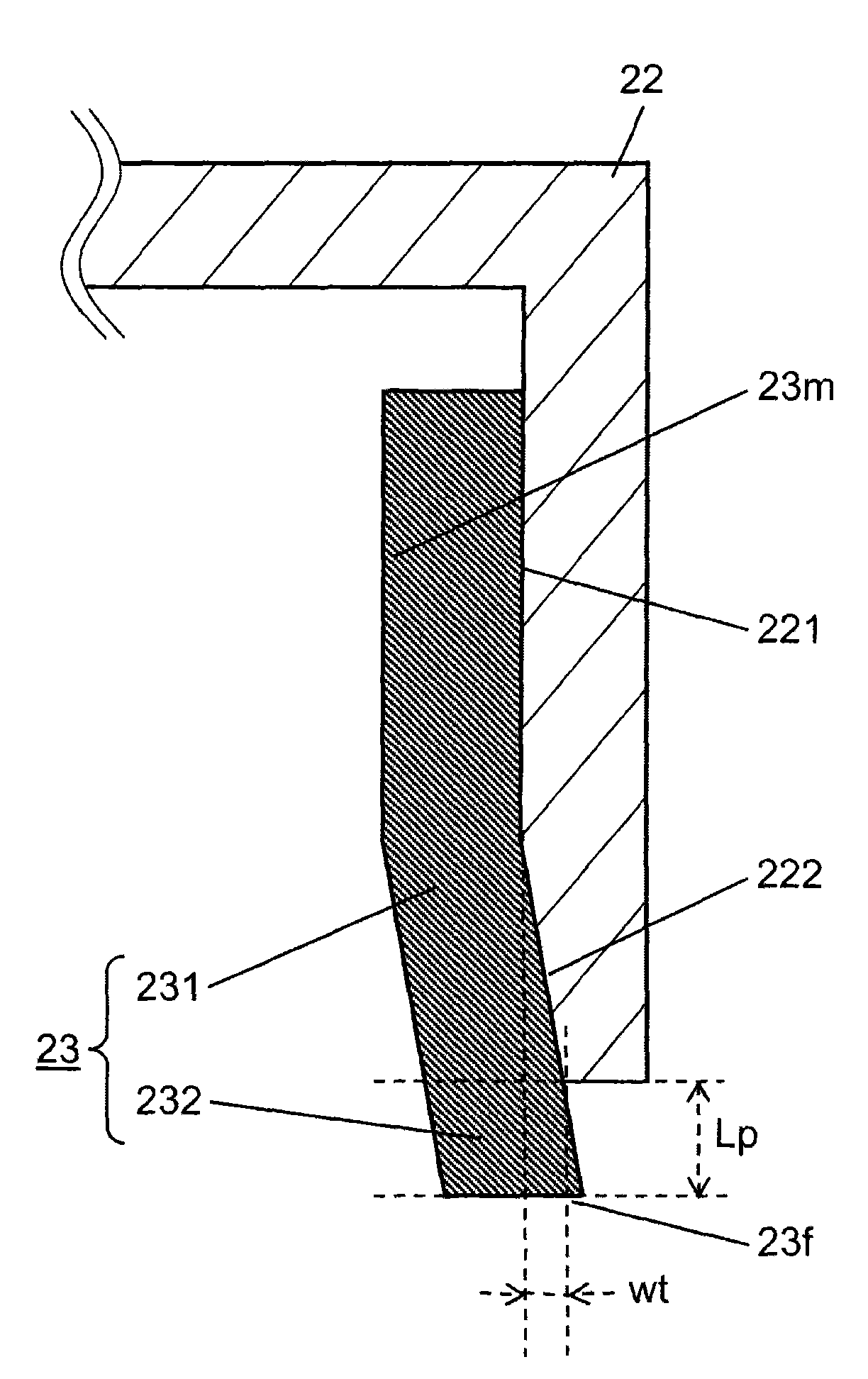

[0026] figure 1 It is a sectional view of the motor in Embodiment 1 of the present invention. First, refer to figure 1 The overall structure of this motor will be described.

[0027] Such as figure 1 As shown, the motor of this embodiment is an outer rotor type brushless DC motor as an example, and includes a stator 10 and a rotor 20 facing the stator 10 and rotatably arranged on the outer peripheral side.

[0028] The stator 10 has a stator core 12 mounted on a wiring board 11 . This stator core 12 is formed as a laminated body in which a plurality of plate-shaped bodies are laminated. On the outer peripheral portion of the stator core 12 , a plurality of teeth serving as magnetic poles are arranged at predetermined intervals along the circumferential direction. In addition, a coil 13 is wound around an arm portion constituting an inner magnetic circuit of each tooth. In this way, the stator 10 in which the coil 13 is wound around the stator core 12 is configured. In a...

Embodiment approach 2

[0061] Figure 5 It is a schematic explanatory diagram of an electronic device (for example, a laser printer) according to Embodiment 2 of the present invention. exist Figure 5 In this example, the motor 30 described in Embodiment 1 is mounted on the wiring board 11 . Furthermore, on this wiring board 11, in addition to the FG pattern 24 ( figure 1 shown), electronic components (not shown) and the like required for the entire electronic device are also loaded together.

[0062] The lower end of the rotating shaft 21 of the rotor 30 passes through the through hole ( figure 1(shown) extends to the lower portion of the wiring board 11, and a gear case 51 is connected to the lower portion of the rotating shaft 21. As described in detail in the first embodiment, the FG pattern 24 is arranged on the wiring board 11 to detect the speed of the motor 30 . The rotation of the motor 30 is decelerated by the gear box 51 . The rotational driving force of the motor 30 is further tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com