Aerospace three linear array CCD camera vision main point on-rail monitoring method

A three-line array and camera technology, applied in the field of aerospace satellite photogrammetry, can solve the problems of inability to perform real-time monitoring, unsuitable for measurement requirements, complicated processes, etc., and achieve the effects of reducing laser beam drift, easy operation, and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

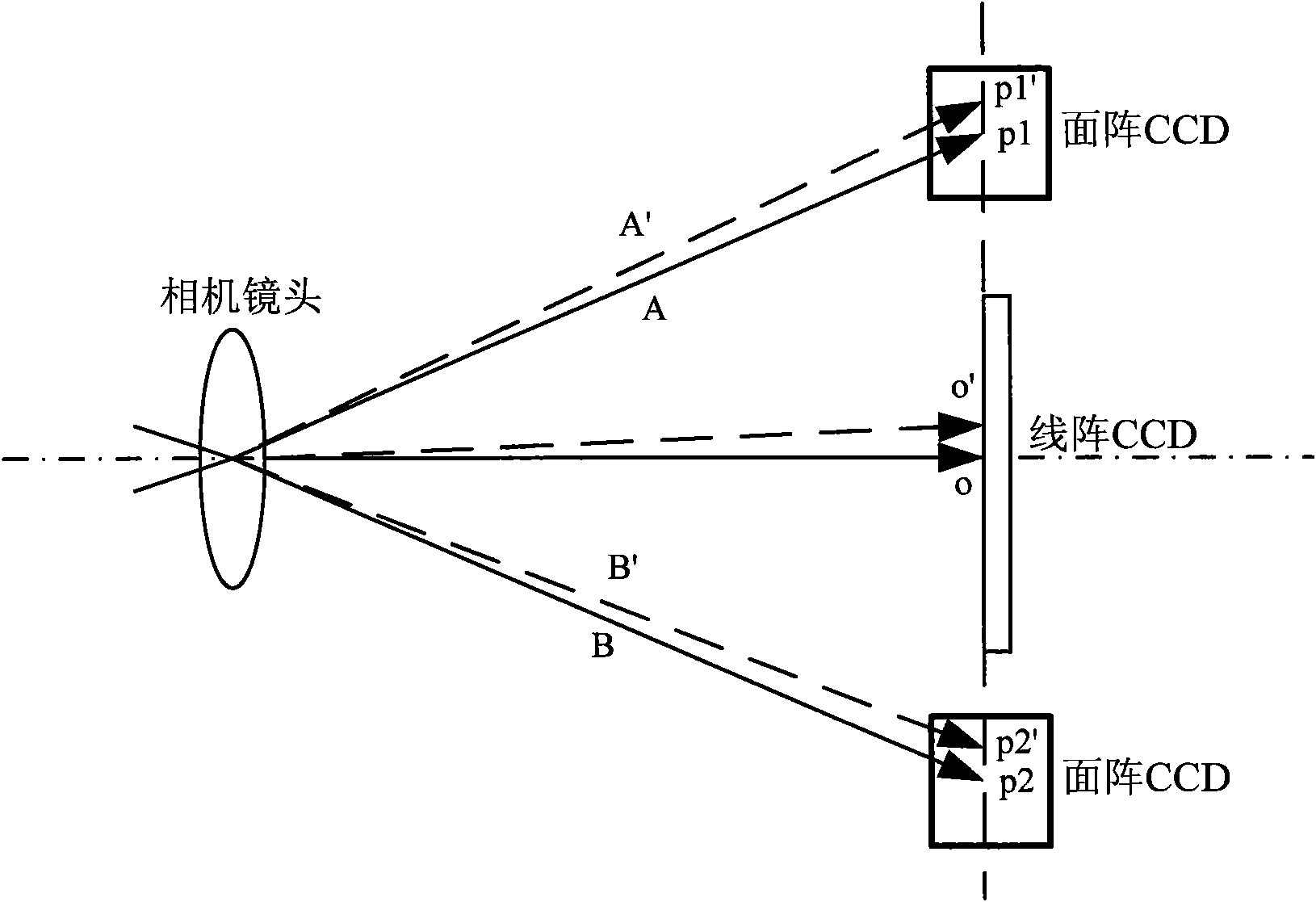

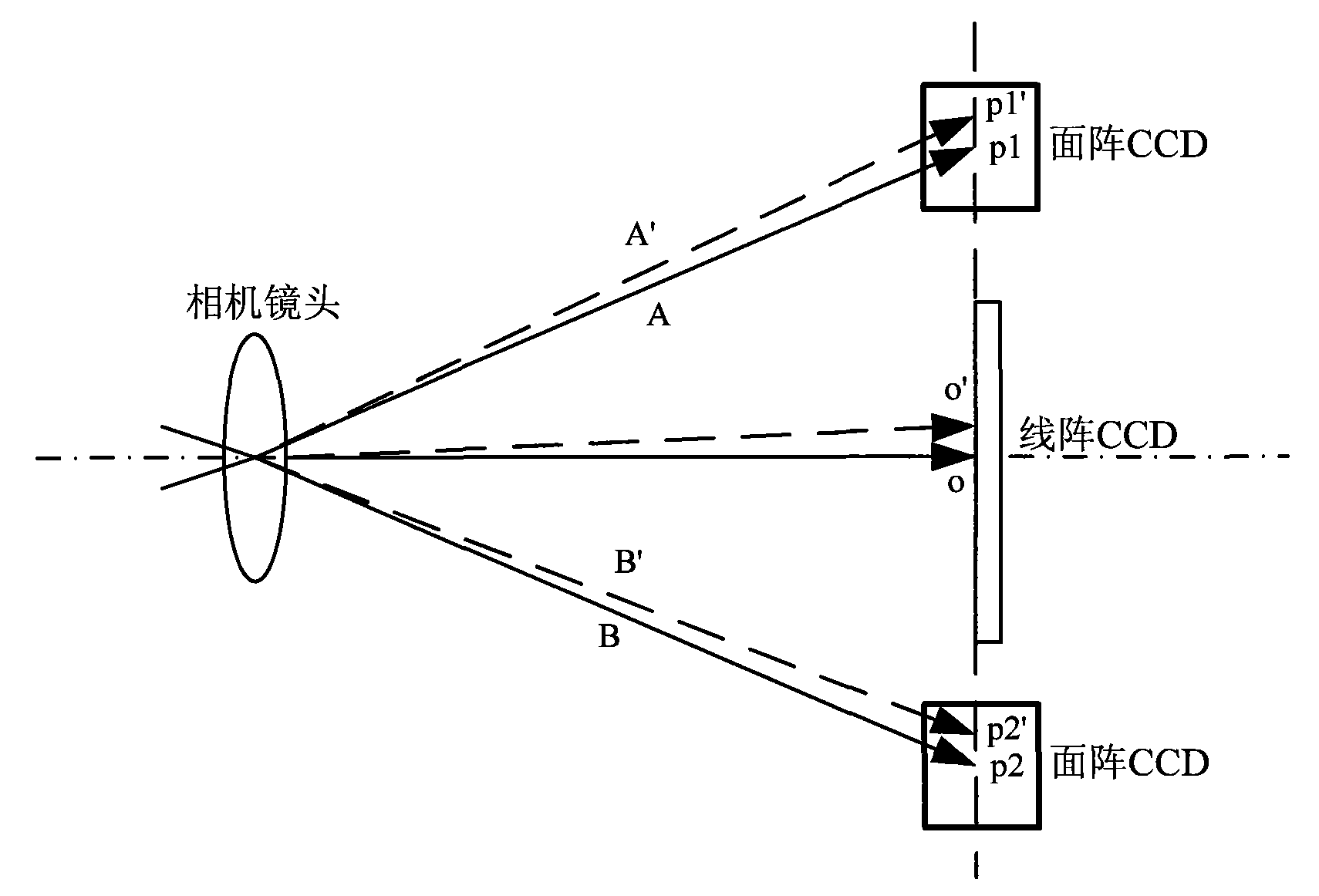

[0018] Such as figure 1 Shown is a schematic diagram of the principle of the monitoring method of the present invention. To monitor the principal point of view of the camera using the method of the present invention, a laser emitting device needs to be arranged on the camera lens, and two receiving phases should be arranged on the line array CCD. The laser emitting device must be rigidly fixed to the camera lens, and the two receiving phases must be rigidly fixed to the linear array CCD.

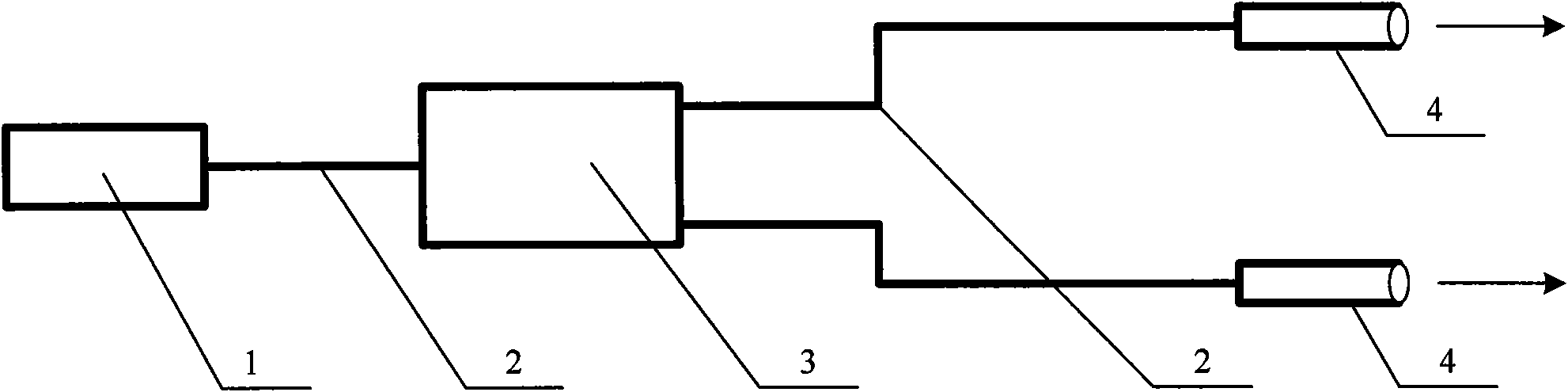

[0019] The structure of the laser emitting device is as follows figure 2 As shown, it includes a laser light source 1, a fiber coupler 3 and two laser collimators 4. The laser light emitted by the laser light source 1 is sent to the fiber coupler 3 through the fiber 2, and the fiber coupler 3 splits the incoming laser light into two paths. Afterwards, they are respectively sent to two laser collimators 4 to obtain collimated lasers and then output. In order to meet the requirements of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com