Bridge protecting pipe using unsaturated composite epoxy resin materials

A composite resin and unsaturated technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems affecting the overall image of urban and rural roads, destructive theft by criminals, and endangering road safety, so as to achieve favorable transportation, safety and reliability, Reduce maintenance costs and facilitate storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific examples are given below in conjunction with the accompanying drawings to further illustrate how the bridge protection pipe made of unsaturated epoxy composite resin material of the present invention is realized.

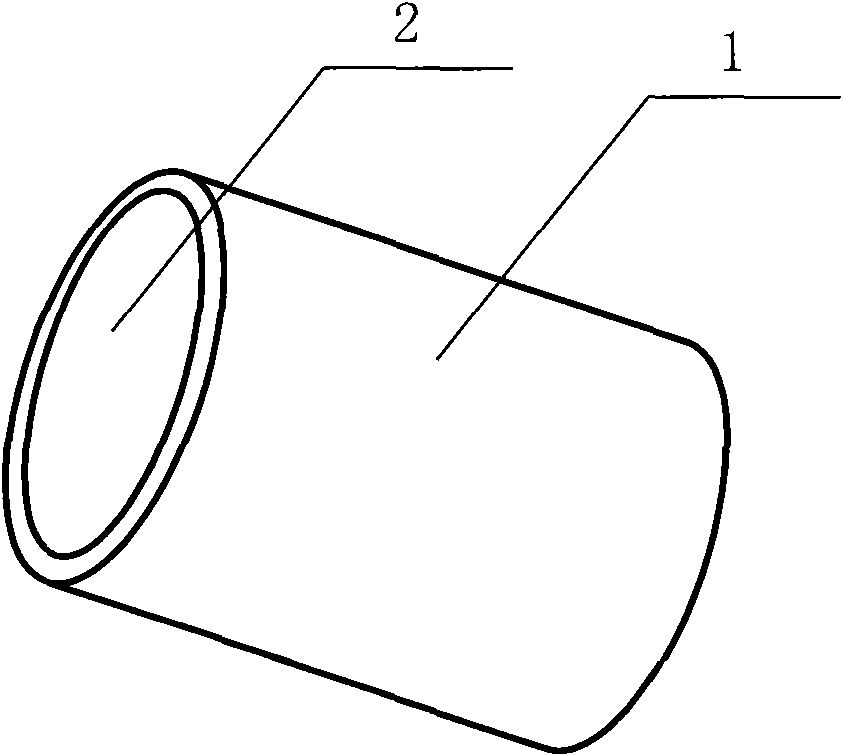

[0027] Such as figure 1 , figure 2 As shown, the unsaturated epoxy composite resin bridge protection pipe of the present invention includes a pipe body 1 formed with a through hole 2 .

[0028] The materials for making bridge protective pipes made of unsaturated epoxy composite resin materials include: unsaturated epoxy composite resin, continuous glass fiber bundles, curing agent and coloring agent, wherein: 45% of unsaturated epoxy composite resin; continuous glass Fiber bundle 40%; curing agent initiator 10%; colorant pigment 5%.

[0029] Wherein, the unsaturated epoxy composite resin is composed of 50% furan resin and 50% organic resin, the curing agent is an initiator, the colorant is a pigment, and the color can be adopted and Resin-compati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com