And application of concrete expansion agent for compensating concrete dry shrinkage

A technology of concrete and expansion agent, applied in the field of expansion agent, can solve the problems of small compensation effect and low hydration activity, and achieve the effect of small water demand, high hydration activity and low requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

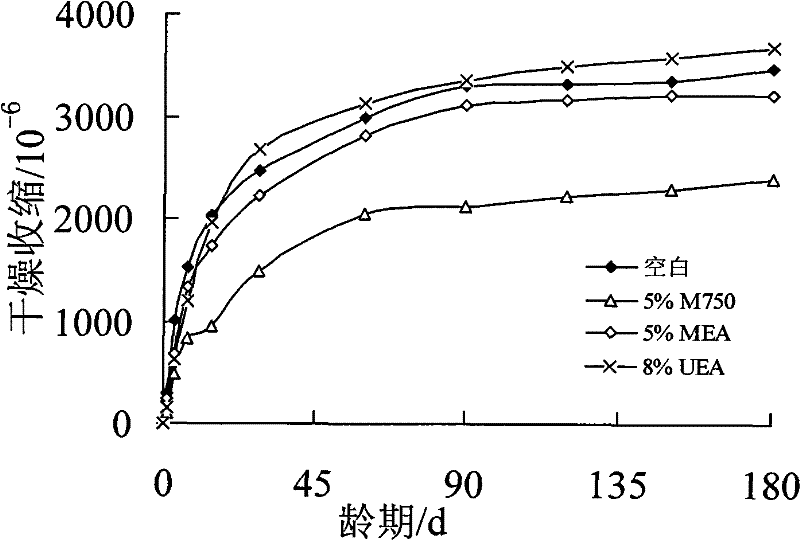

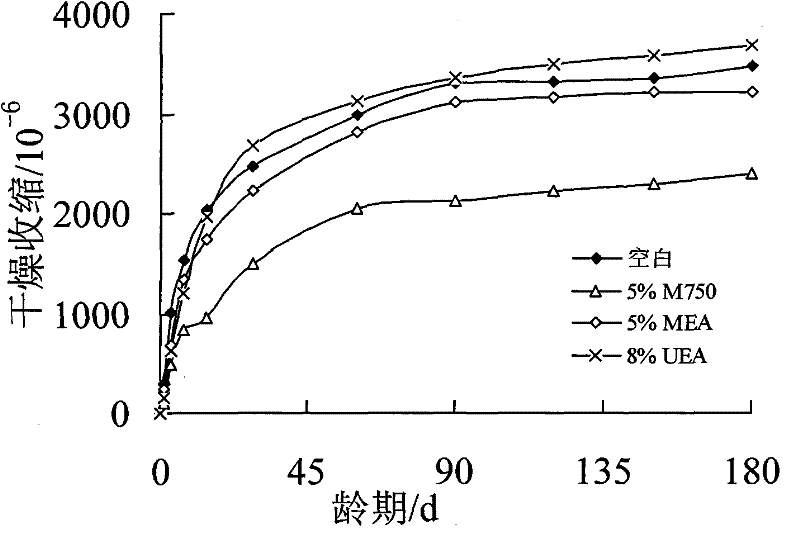

[0014] Use a jaw crusher to crush the magnesite into small particles with a particle size of <2cm; calcinate the crushed magnesite raw ore particles at 750°C, keep it at this temperature for 80min, and cool it to room temperature in the air Then use a ball mill to grind the calcined product to a certain fineness (80um sieve, 3% to 10% of the remainder of the sieve), detect its hydration activity with the citric acid method, detect its MgO content with an X fluorescence analyzer, and test its calcined For details, see Table 1. Then seal it and pack it into concrete expansion agent M750. The product complies with the requirements of JC476-2001 concrete expansion agent industry standard.

preparation Embodiment 2

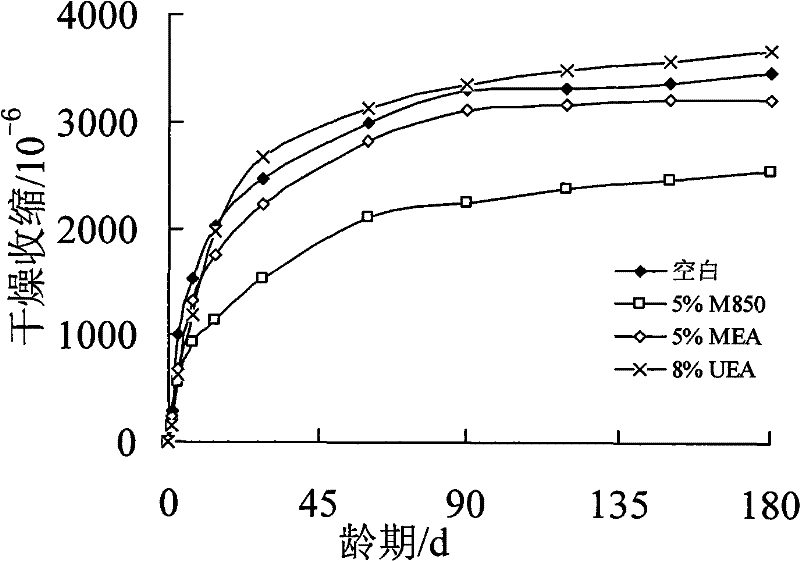

[0016] Use a jaw crusher to crush magnesite into small particles with a particle size of <2cm; calcinate the crushed magnesite raw ore particles at 850°C, keep at this temperature for 50min, and cool to room temperature in the air Then use a ball mill to grind the calcined product to a certain fineness (80um sieve, 3% to 10% of the remainder of the sieve), detect its hydration activity with the citric acid method, detect its MgO content with an X fluorescence analyzer, and test its calcined For details, see Table 1. Then it is sealed and packaged into concrete expansion agent M850. The product complies with the requirements of JC476-2001 concrete expansion agent industry standard.

[0017] Table 1

[0018]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com