Security punching machine capable of realizing jogging control of punching head

A kind of jog control and safety technology, applied in the field of stamping machinery, can solve the problems of physical injury, reduce work efficiency, inconvenient operation, etc., and achieve the effect of high safety, convenient operation and high control precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

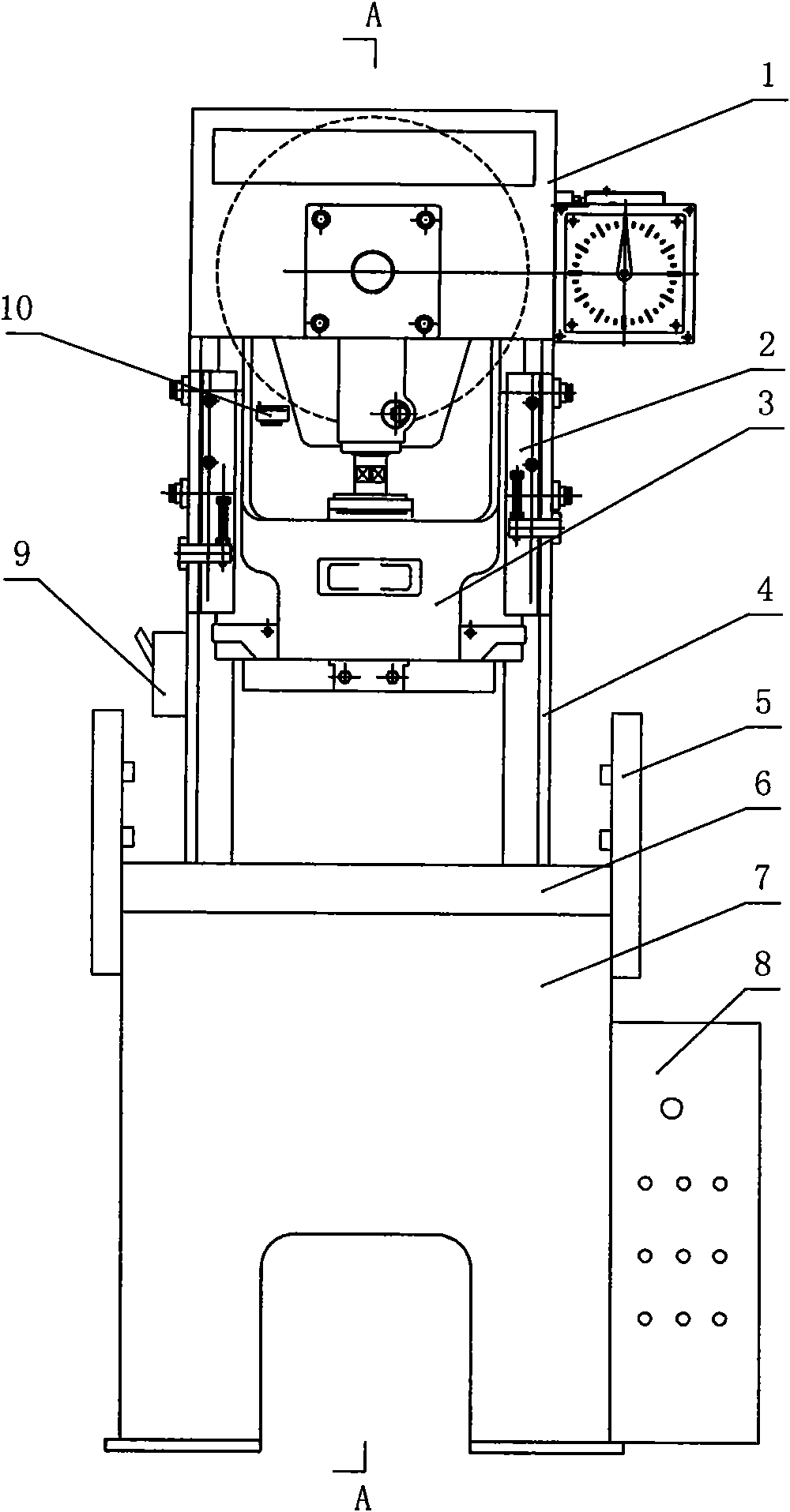

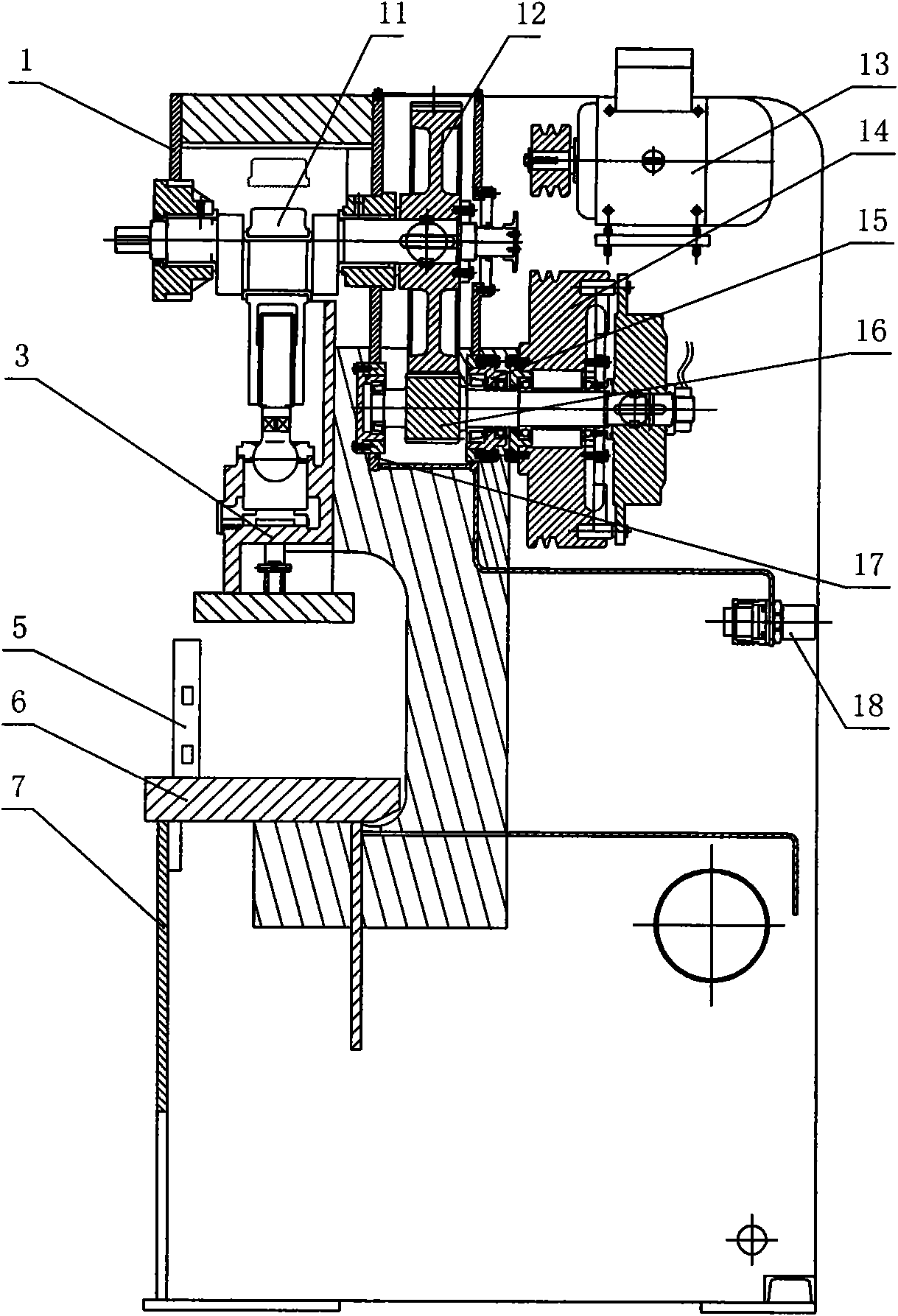

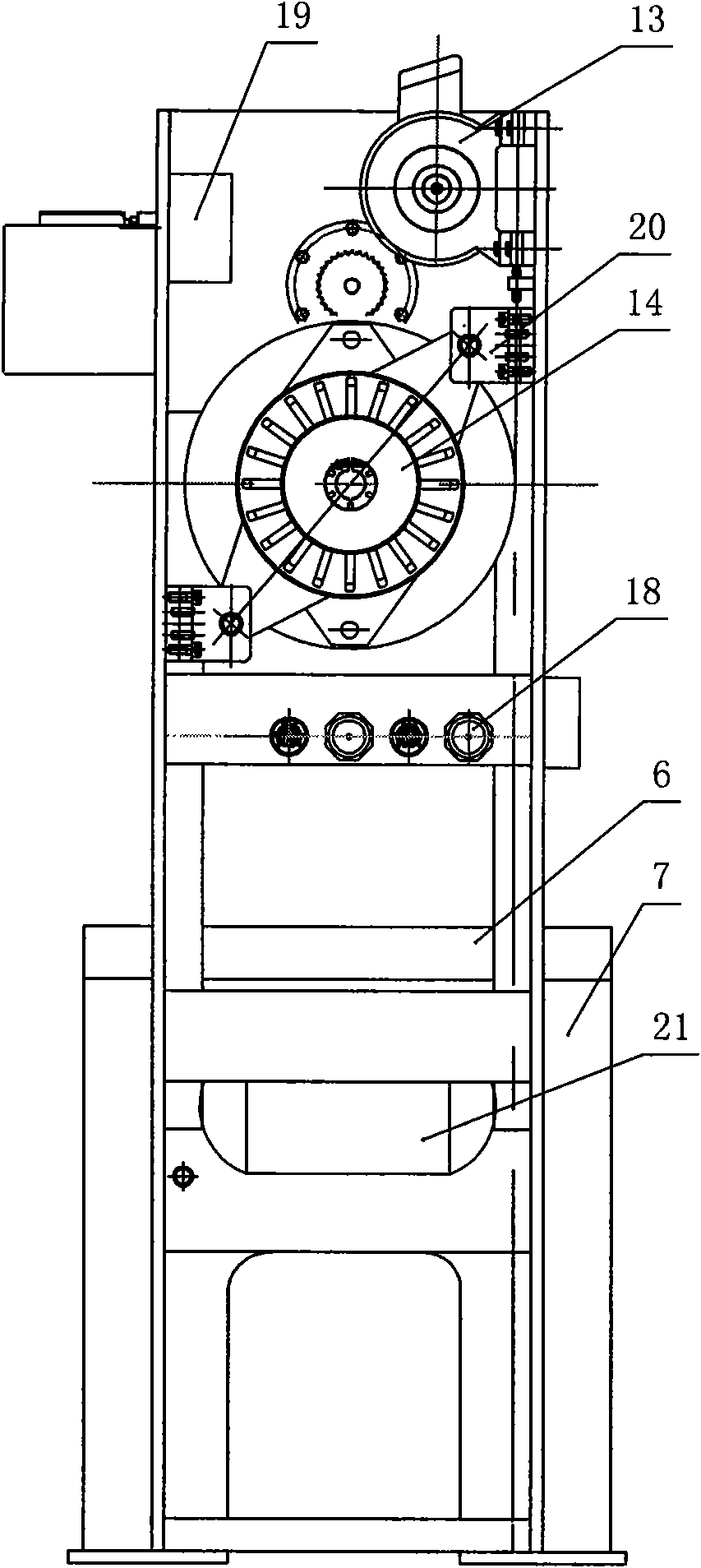

[0020] A safety punching machine capable of realizing punch inching control, consisting of a workbench 6, a frame 4, a punch 3, a crankshaft 11, and a drive motor 13, the workbench is fixed on the upper surface of a base 7, and the upper surface of the base is fixed Install the rack. The vertical lifting movement of the punch is installed on the side plate of the frame at the top of the workbench, and the sliding block both sides of the punch are guided and installed on the frame side plate by the bead 2. Rotate and install a crankshaft on the top plate 1 on the upper part of the frame, the connecting sleeve on the upper part of the punch is fitted on the front end of the crankshaft, and the rear end of the cranks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com