Safe scalpel with assembled steel handle

A scalpel, surgical blade technology, applied in the direction of dissection instruments, etc., to achieve the effect of eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] Embodiment: a kind of safety scalpel with steel handle loading and unloading

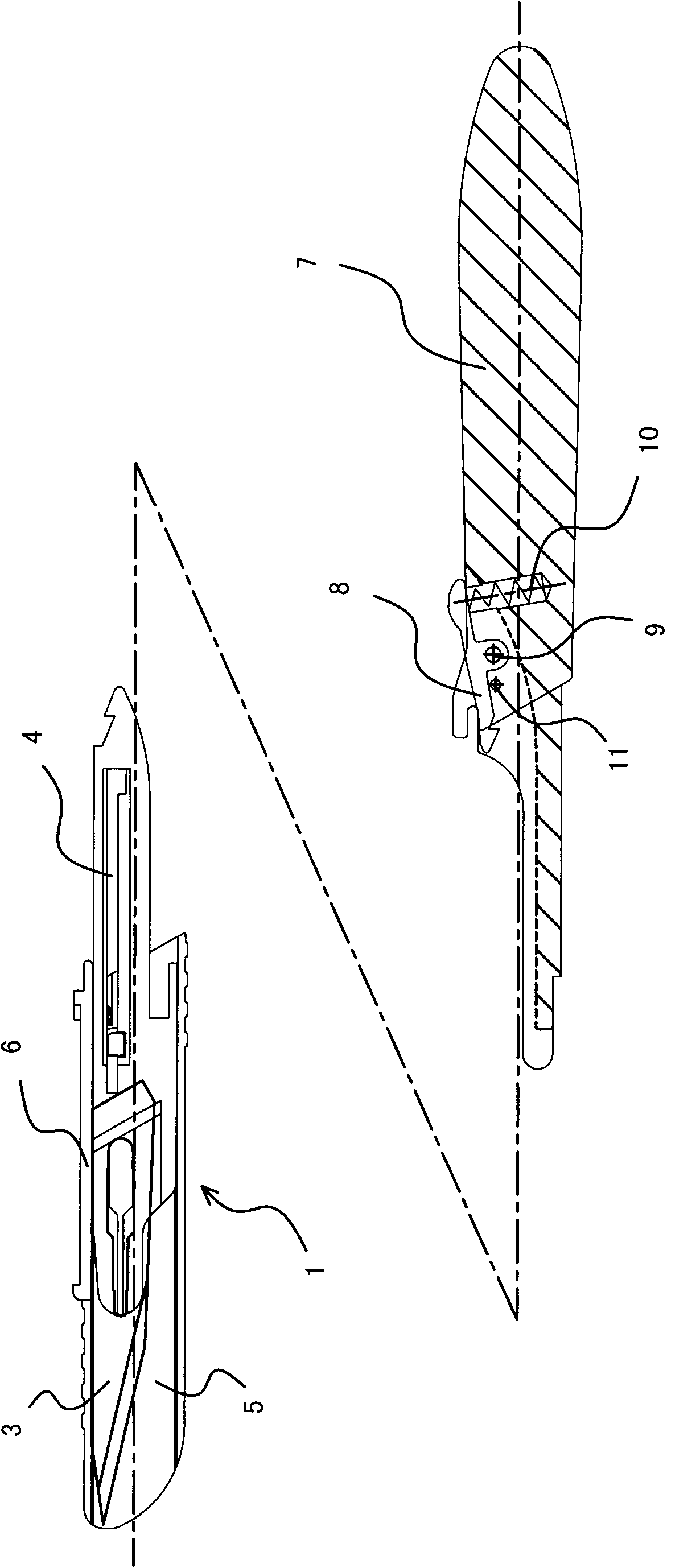

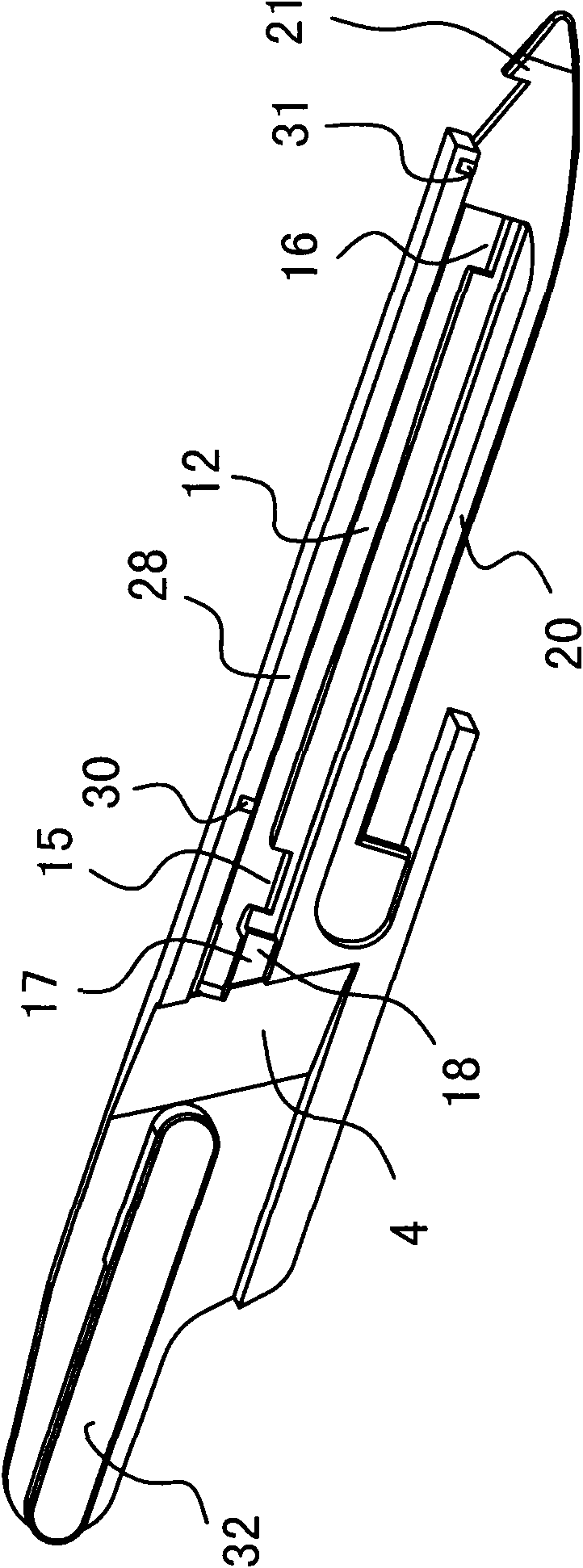

[0048] like figure 1 Shown, this scalpel is made up of guard body assembly 1 and steel handle 7 two parts, and wherein guard body assembly 1 is made up of scalpel 3, adorn knife body 4, knife sheath 5 and safety latch 6. The knife body 4 is a strip-shaped structural part, the surgical blade 3 is fixed on the front of the knife body 4, the knife cover 5 is slidably fitted on the knife body 4, and the main body of the safety latch 6 is a sliding bar structure and is slidably connected to the knife body 4 on.

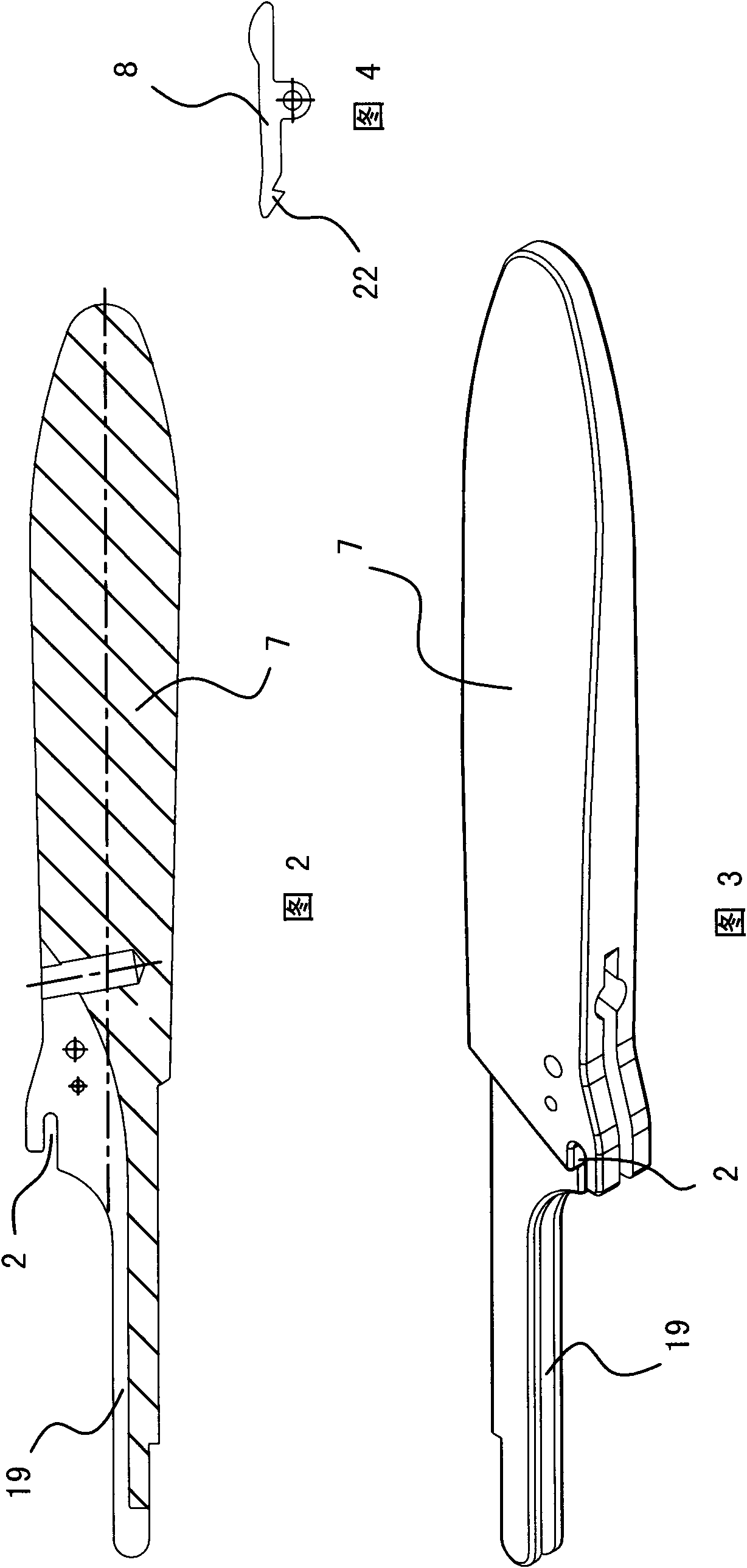

[0049] like figure 2 , image 3 As shown, the steel handle 7 is a scalpel handle that can be assembled and disassembled with the knife guard body assembly 1. The steel handle 7 front portion is provided with a second plug-in structure, and the corresponding second plug-in structure is provided at the knife body 4 rear portion. There is a first plug-in structure, and the first plug-in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com