Mounting method for air spring vehicle chasis and its supporting rod

A technology of air suspension and installation method, which is applied in the direction of suspension, elastic suspension, vehicle parts, etc., which can solve the problems of crushed chassis, cracking of air bag rubber, inconvenient installation and construction, etc. The adjustment is small, the effect of using and adjusting is quick

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the utility model is described in further detail:

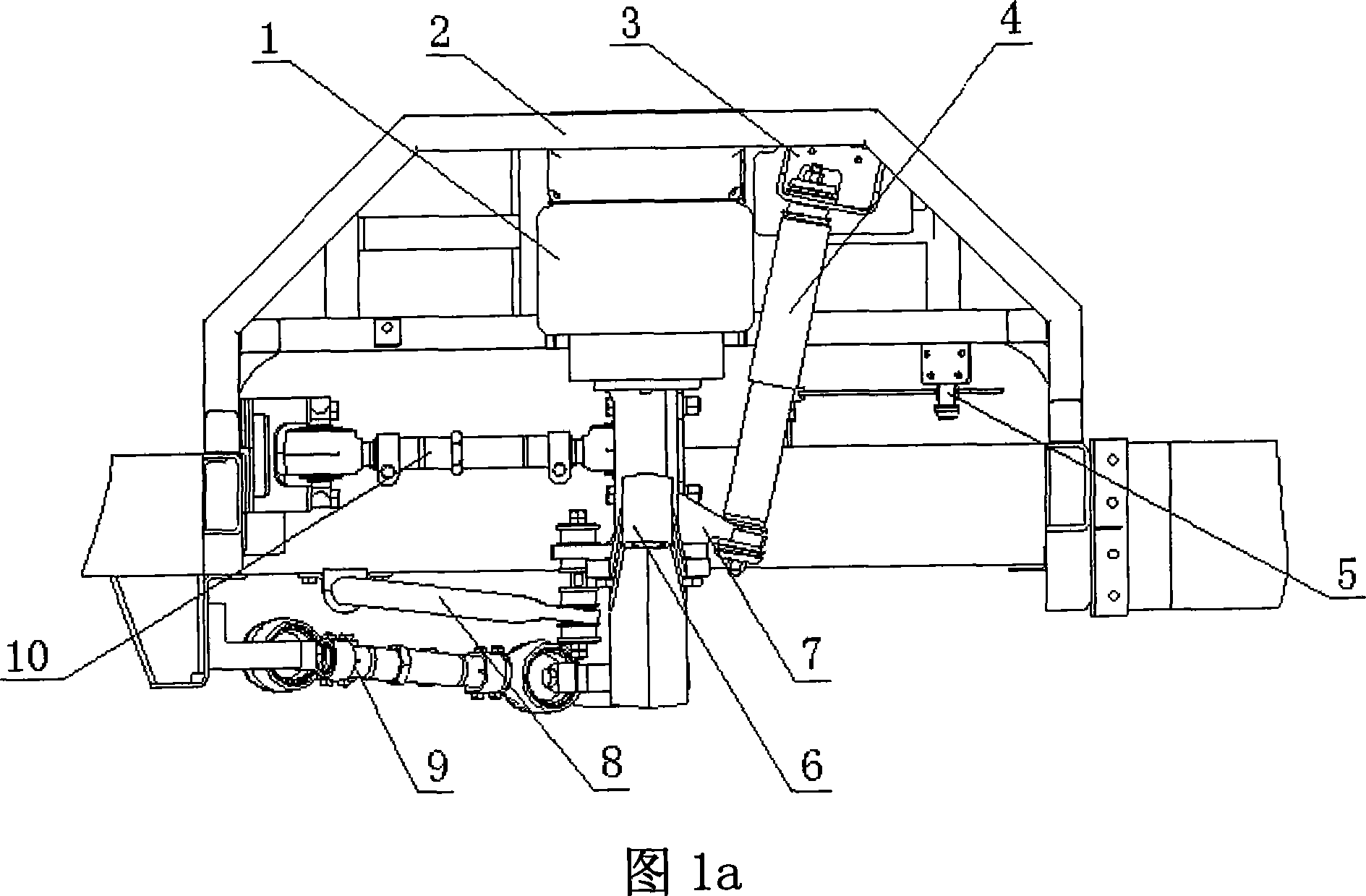

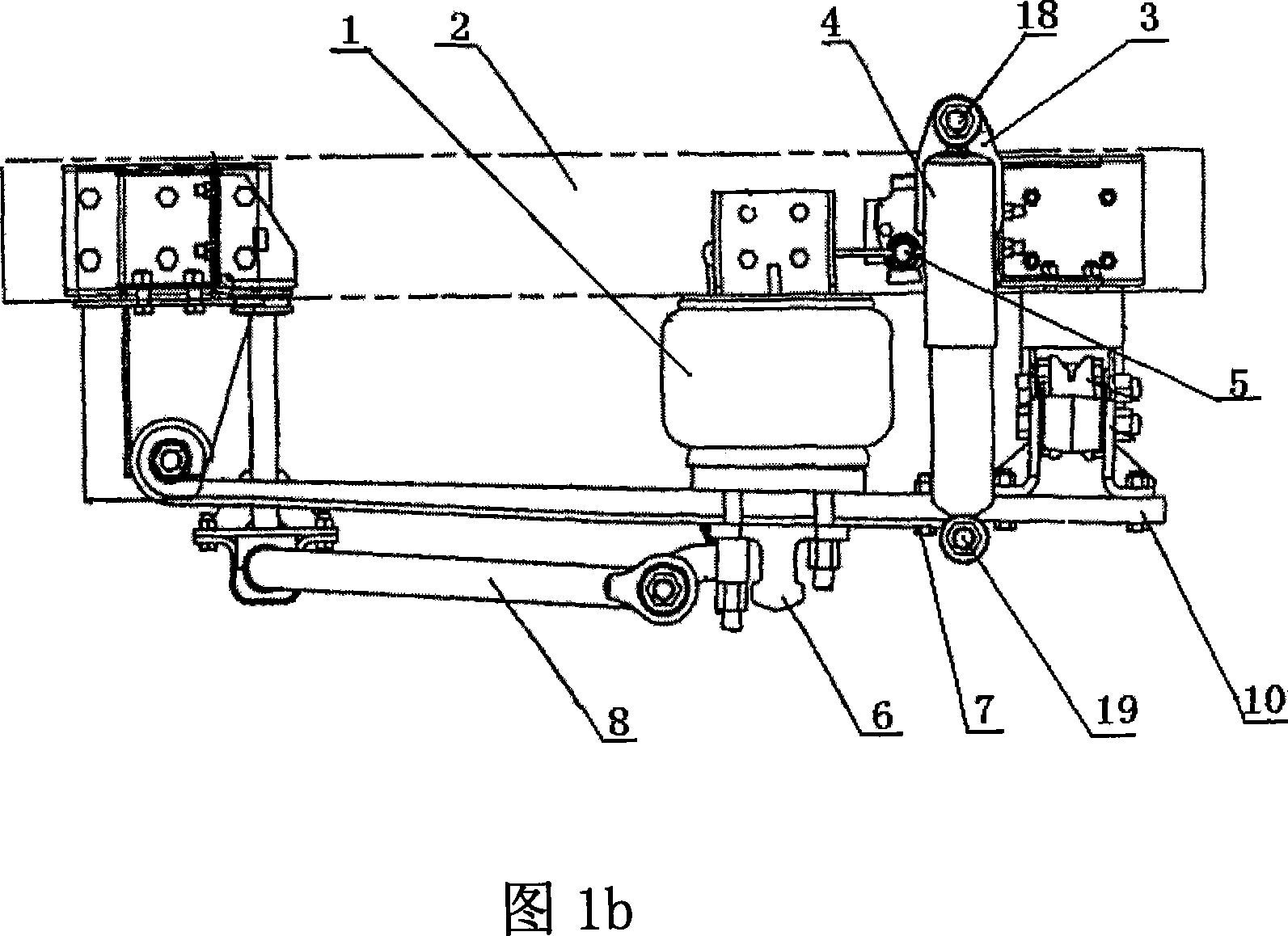

[0020] Referring to Fig. 1a and Fig. 1b, the existing air suspension vehicle chassis is installed by first using a platform to pad the frame 2, pushing the axle 6 underneath, and then installing a stabilizer bar between the frame 2 and the axle 6 8. V-shaped thrust rod 9, longitudinal thrust rod 10, airbag 1, shock absorber 4, height control sensor 5 and various pipelines and other components. After completion, the vehicle chassis is hoisted and transferred to the vehicle assembly production line for vehicle assembly.

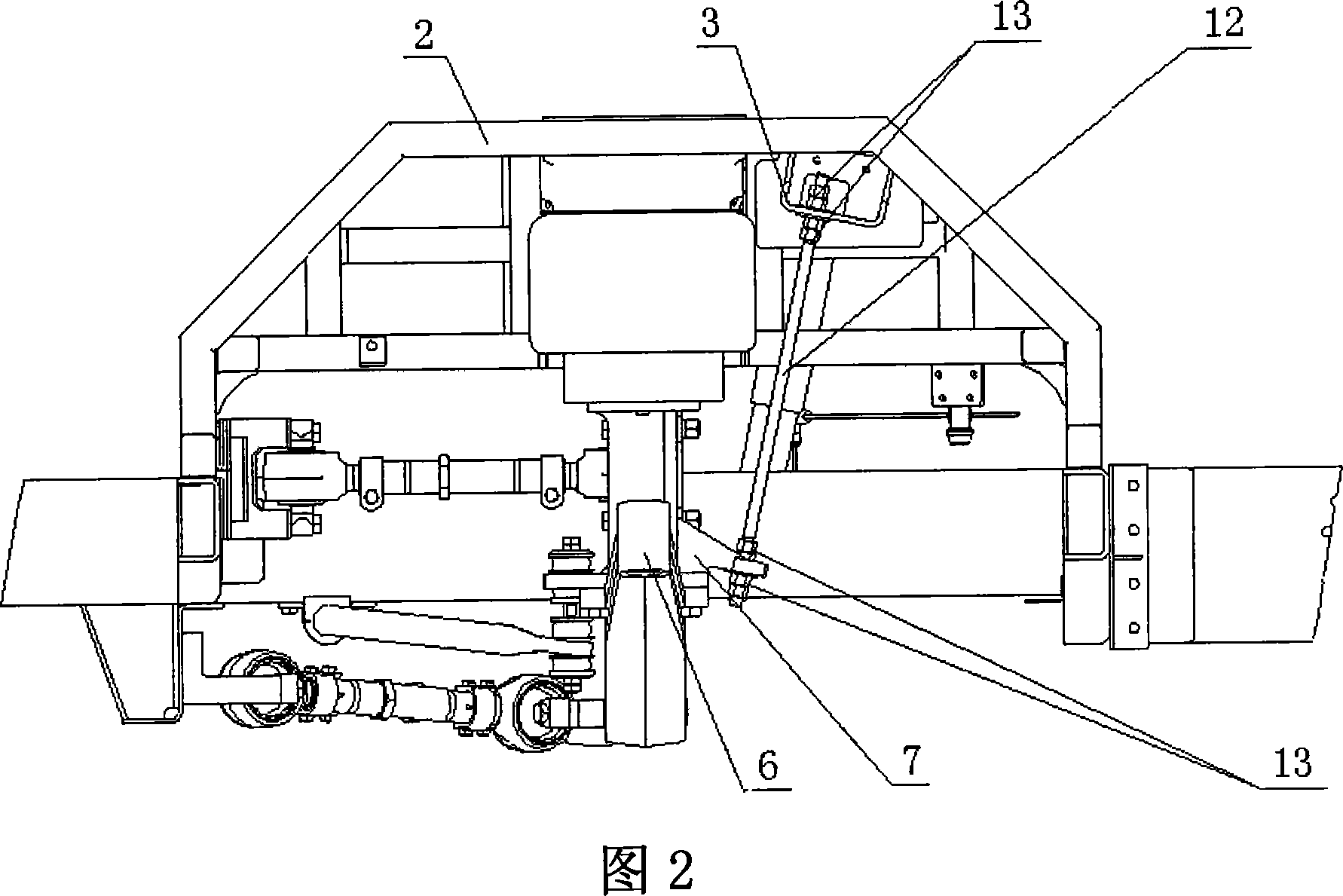

[0021] Referring to Fig. 2 and Fig. 3, the installation method of the air suspension vehicle chassis of the present invention, first lift the vehicle frame 2, install the support rod 11 between the vehicle frame 2 and the vehicle axle 6 below, and adjust the support height of the support rod 11 , so that the vehicle frame 2 is withi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com