Assembly method for forming a seating structure of a vehicle seat, and seating structure

An assembly method and seat technology, applied to vehicle seats, seat frames, special positions of vehicles, etc., can solve problems such as damage and dislocation of stoppers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

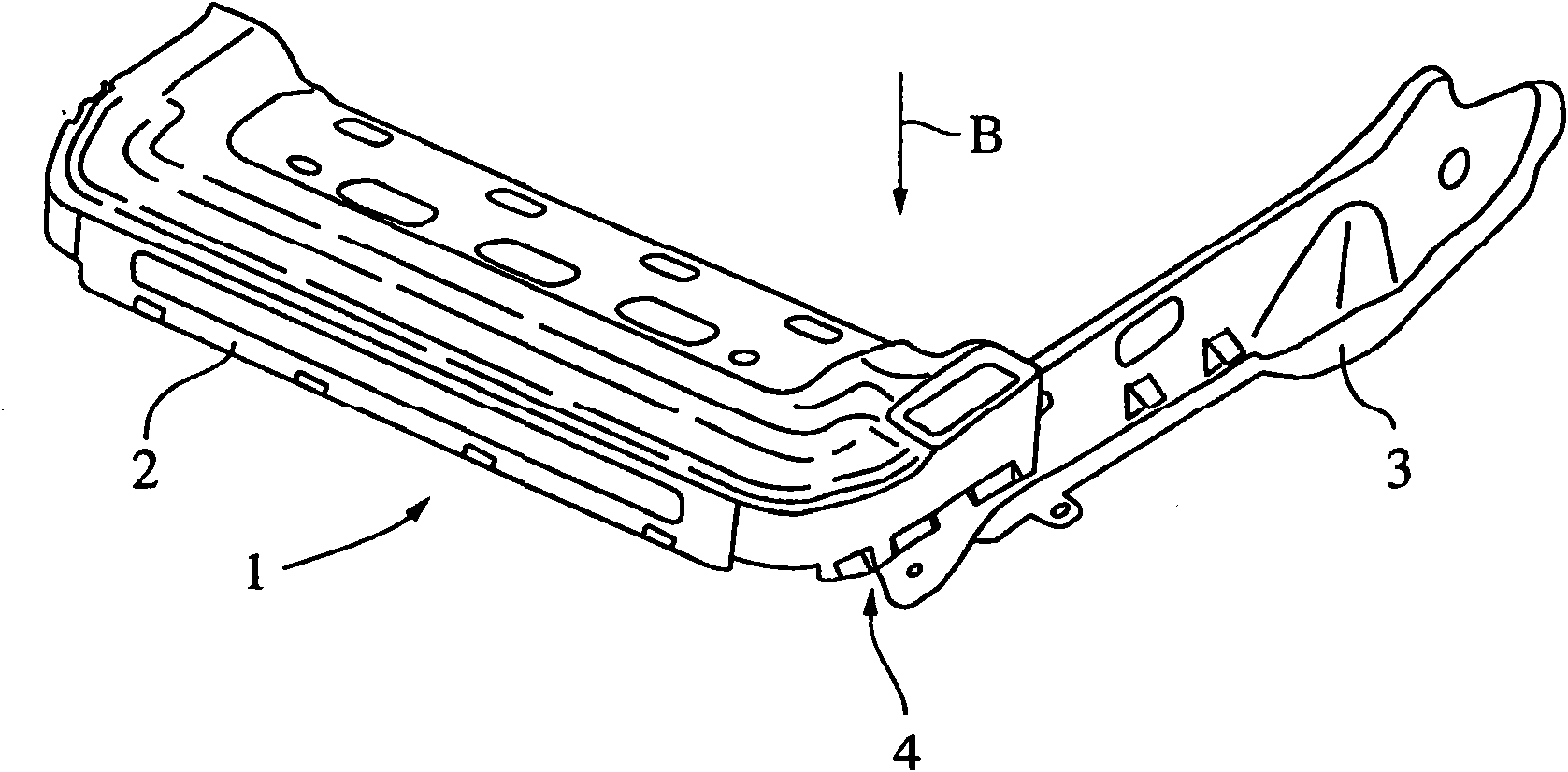

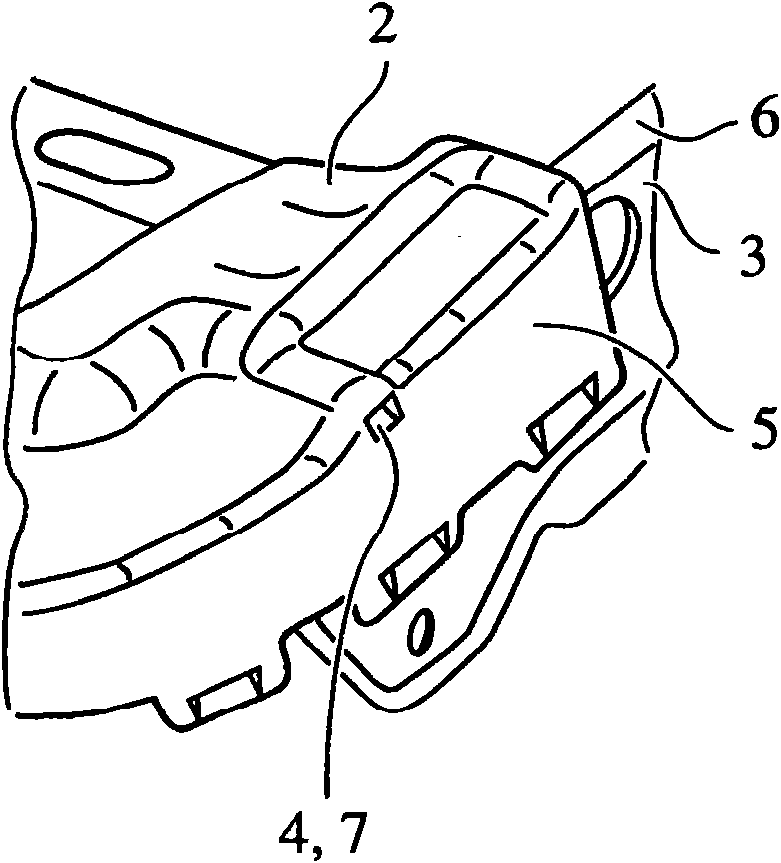

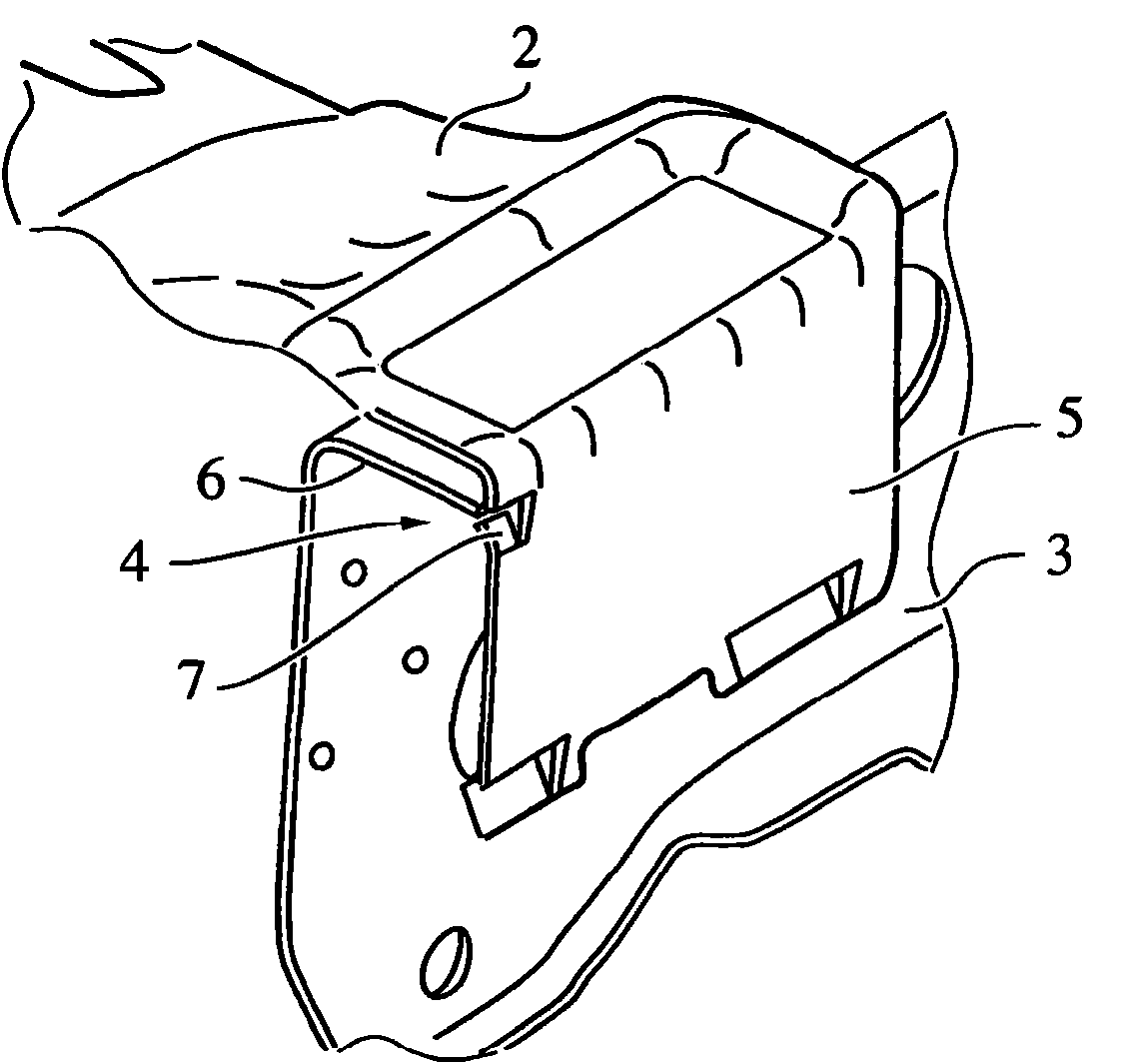

[0029] Figures 1 to 4 A first embodiment of a cross member 2 and a longitudinal member 3 as part of a seat structure 1 for a vehicle seat is schematically shown.

[0030] The seat structure 1 is preferably composed of different frame parts which have a main direction of extension and which are connected to one another to form a frame-shaped structure. In particular, the frame parts are fixed to one another in their final position by material bonding, preferably by welding; however, it is also possible to glue, rivet or screw the frame parts to one another. Prior to this final fastening, it is preferably provided that the frame parts are directly connected to one another in a form-fitting manner, in particular latched together. In the first embodiment, it is specified that a front cross member 2 of the seat structure 1 is configured such that it can be latched by pushing from above (ie in the Z direction of the vehicle) to Stringer 3 on. Through the latch engagement, not on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com