Two-dimensional vertical-cavity surface-emitting laser array with high light beam quality

A vertical cavity surface emission, high-beam technology, applied in lasers, laser components, semiconductor lasers, etc., can solve problems such as complex structures, increased overall device volume, and limited laser power density, to achieve expanded application fields and reliability High, improve the effect of output beam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

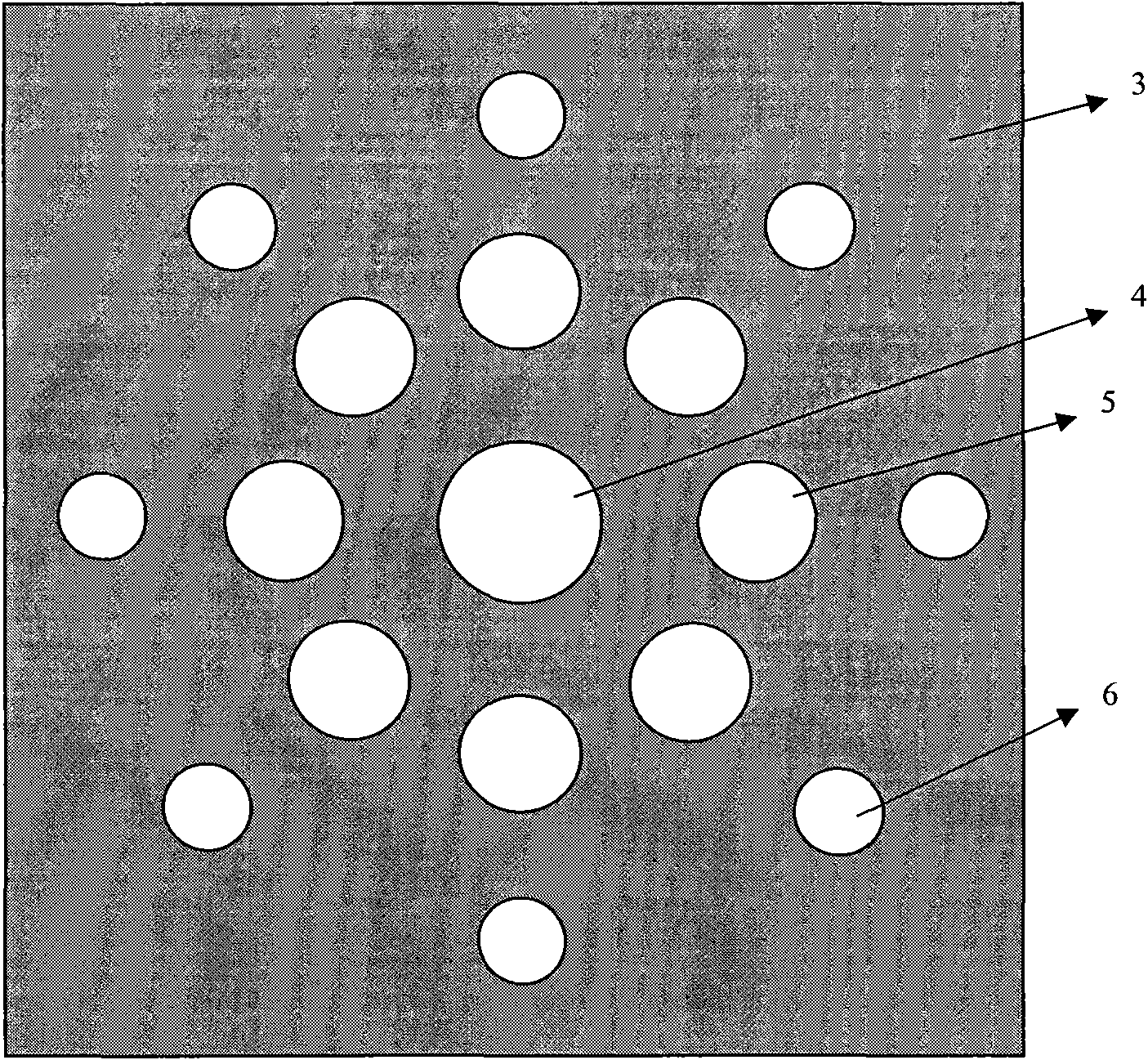

[0011] The invention according to figure 2 The structure shown is implemented, wherein the surface electrode 3 is made by evaporation, the diameter of the light exit hole of the single unit laser device 4 in the central area is 200 μm, and the power is 530 mW, and the diameter of the light exit hole of the first ring unit laser device 5 is 150 μm. The diameter of the light exit hole of the second ring unit laser device 6 is 100 μm, and the power is 100 mW. The distance between the first ring and the single unit laser device 4 in the central area is 300 μm, and the distance between the second ring and the first ring is 250 μm. Firstly, a set of photolithography masks required is fabricated according to the structure, and then the traditional oxidation-limited vertical cavity surface emitting laser process flow is used to fabricate the two-dimensional vertical cavity surface emitting laser array with high beam quality. The unit laser devices in this technical solution all use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com