High-temperature metallurgical furnace and method for making compound insulation structure used for high-temperature metallurgical furnace

A technology of high temperature treatment and composite heat preservation, which is applied in the field of heat insulation materials, metallurgical furnaces and high temperature treatment furnaces, can solve the problems of poor heat insulation effect of heat preservation structure and high manufacturing cost, achieve good heat insulation effect and reduce energy consumption , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

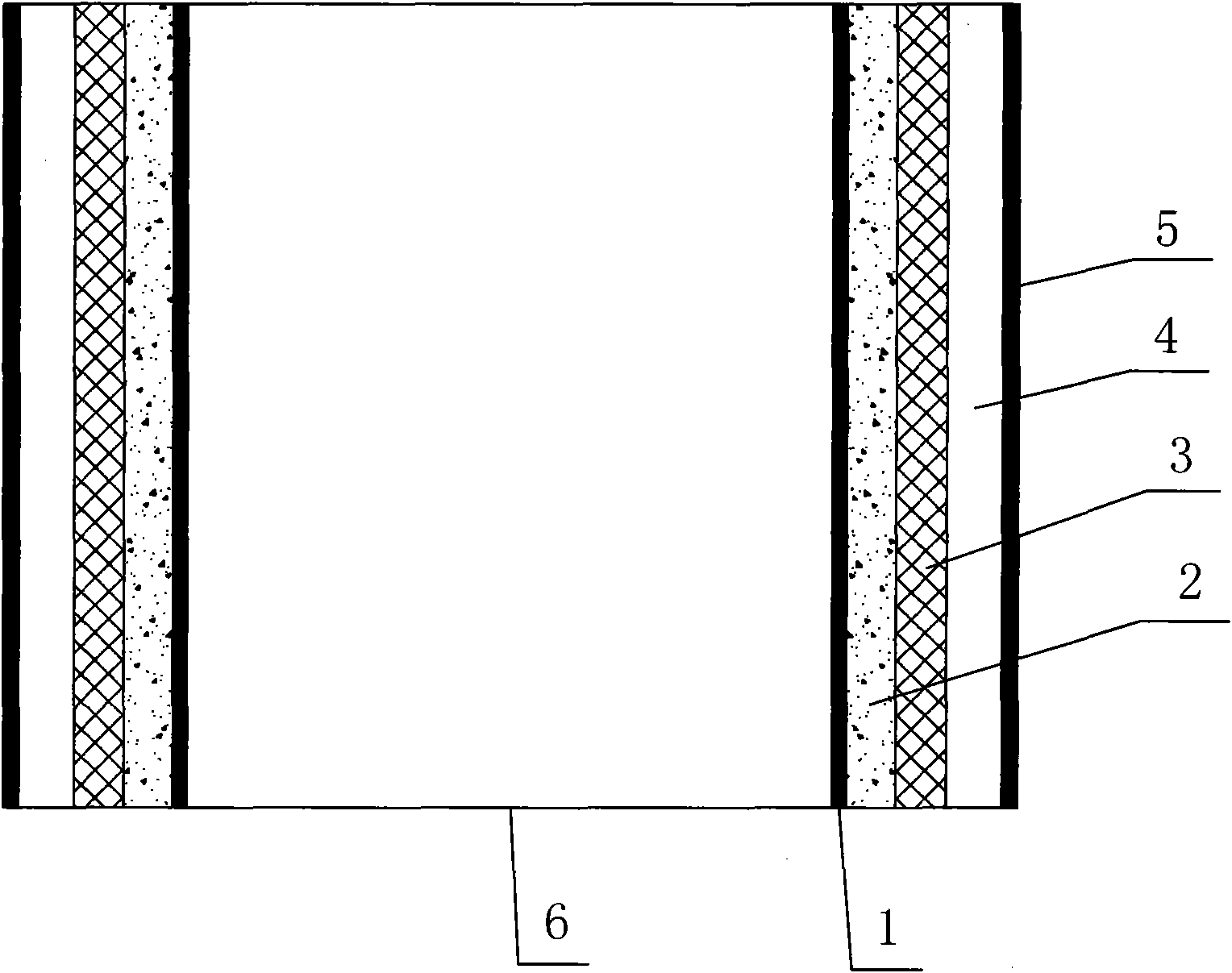

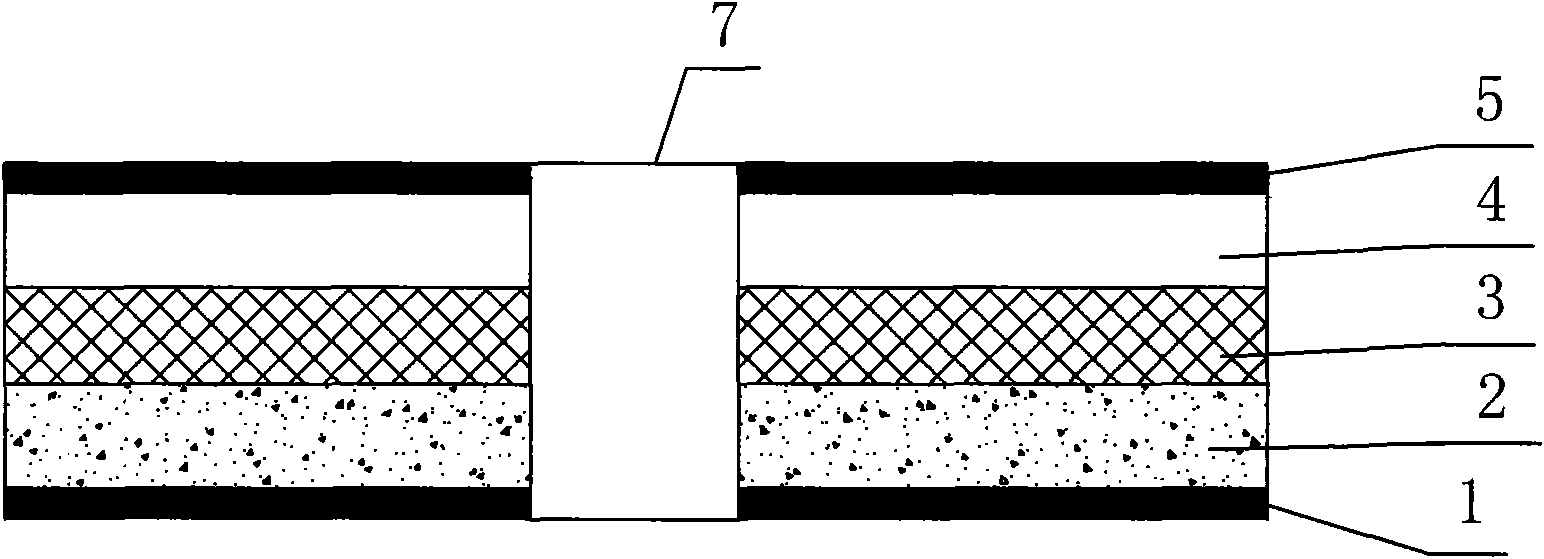

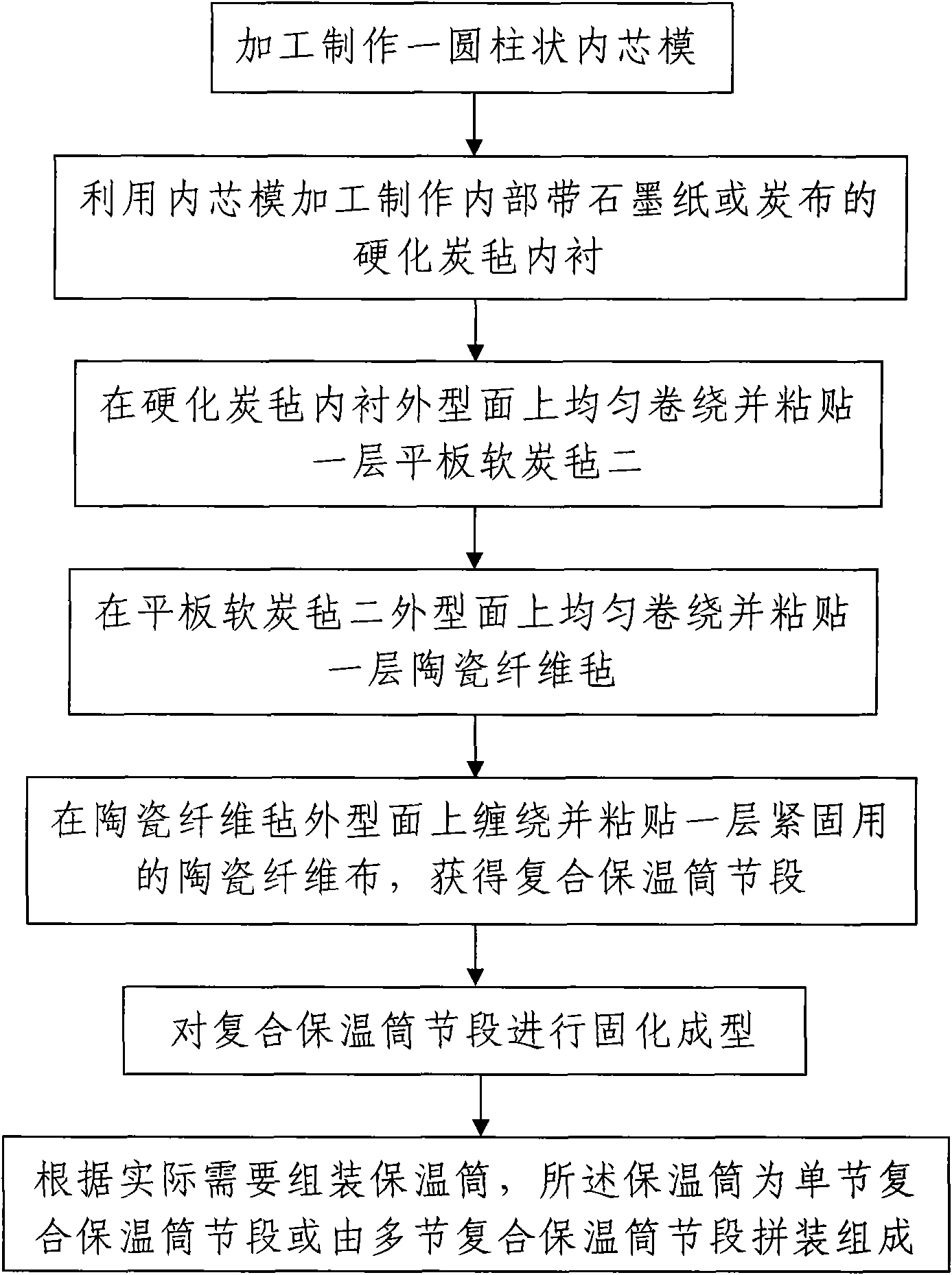

[0038] Such as figure 1 , figure 2As shown, the heat preservation structure made by the present invention includes a cylindrical heat preservation cylinder 6 and a heat preservation cover 7 and a heat preservation bottom plate buckled at the upper and lower openings of the heat preservation cylinder 6. The heat preservation cover 7 and the heat preservation bottom plate are both circular and both The structure is the same. Such as image 3 As shown, the manufacturing method of the high-temperature metallurgical furnace and the high-temperature treatment furnace composite insulation structure of the present invention comprises the following steps:

[0039] Step 1, making the insulation cylinder 6, the insulation cylinder 6 is a single-section insulation cylinder segment or is composed of multiple insulation cylinder segments with the same structure, the inner diameter of the insulation cylinder 6 is 300-2000mm, and the outer diameter is 360-2500mm and a height of 500-4000mm...

Embodiment 2

[0065] In this embodiment, in step 102, the graphite paper 1 is first wound on the steel mandrel, and then the flat soft carbon felt impregnated with phenolic resin is evenly wound on the outer surface of the graphite paper 1, and then the steel mandrel is wrapped. The mandrel, together with the graphite paper 1 and the flat soft carbon felt wound on it in turn, are placed in a carbonization furnace as a whole and carbonized at a temperature of 1000°C to make a density ≥ 0.2g / cm 3 1. A cylindrical hardened carbon felt lining 2 with an inner diameter of 1000 mm and a thickness of 40 mm. The raw materials in the high-temperature adhesive described in steps 103 and 202 are phenolic resin, SiC and SiO 2 The weight ratio is 9:1:1.5, and the thickness of the flat soft carbon felt 2 3 is 40mm. The thickness of the ceramic fiber felt 4 in steps 104 and 203 is 60 mm. The thickness of the ceramic fiber cloth 5 in steps 105 and 204 is 5 mm. In step 106, place the segment of the compos...

Embodiment 3

[0069] In this embodiment, in step 102, the graphite paper 1 is first wound on the steel mandrel, and then the flat soft carbon felt impregnated with phenolic resin is evenly wound on the outer surface of the graphite paper 1, and then the steel mandrel is wrapped. The mandrel, together with the graphite paper 1 and the flat soft carbon felt wound on it in turn, are placed in a carbonization furnace as a whole and carbonized at a temperature of 1200°C to make a density ≥ 0.2g / cm 3 1. A cylindrical hardened carbon felt lining 2 with an inner diameter of 2000 mm and a thickness of 60 mm. The raw materials in the high-temperature adhesive described in steps 103 and 202 are phenolic resin, SiC and SiO 2 The weight ratio is 12:2:3, and the thickness of the flat soft carbon felt 2 3 is 100mm. The thickness of the ceramic fiber felt 4 in steps 104 and 203 is 100mm. The thickness of the ceramic fiber cloth 5 in steps 105 and 204 is 8mm. In step 106, place the segment of the composi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com