Shift fork of shoe with tolerance balancing

A technology for shift forks and sliding seats, which is applied to components with teeth, belts/chains/gears, mechanical control devices, etc., and can solve problems such as inappropriate assembly of sliding seats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

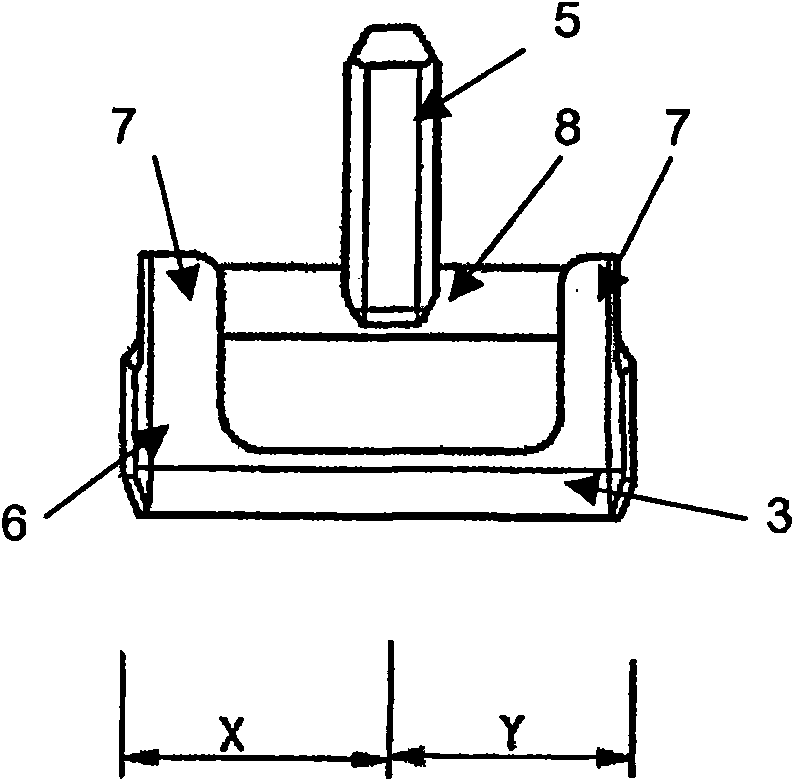

[0036] figure 1 The front view of the shift fork system 1 with the shift fork 2 and the assembled carriage 3 is shown. The selector fork 2 here has a substantially V-shaped and U-shaped cross section with two arms 4 . The two arms 4 spread out a parallel to figure 1 The plane of the drawing plane orientation. On the outer end of each arm 4 on the inside of the selector fork 2 , more precisely on the inside of the arm 4 , a slide 3 is arranged in the fastening section A, the slide 3 resting on the selector fork 2 In the installed state, it fits into a groove of a shift sleeve (not shown), which is arranged between the two arms 4 and the sliding seat 3 .

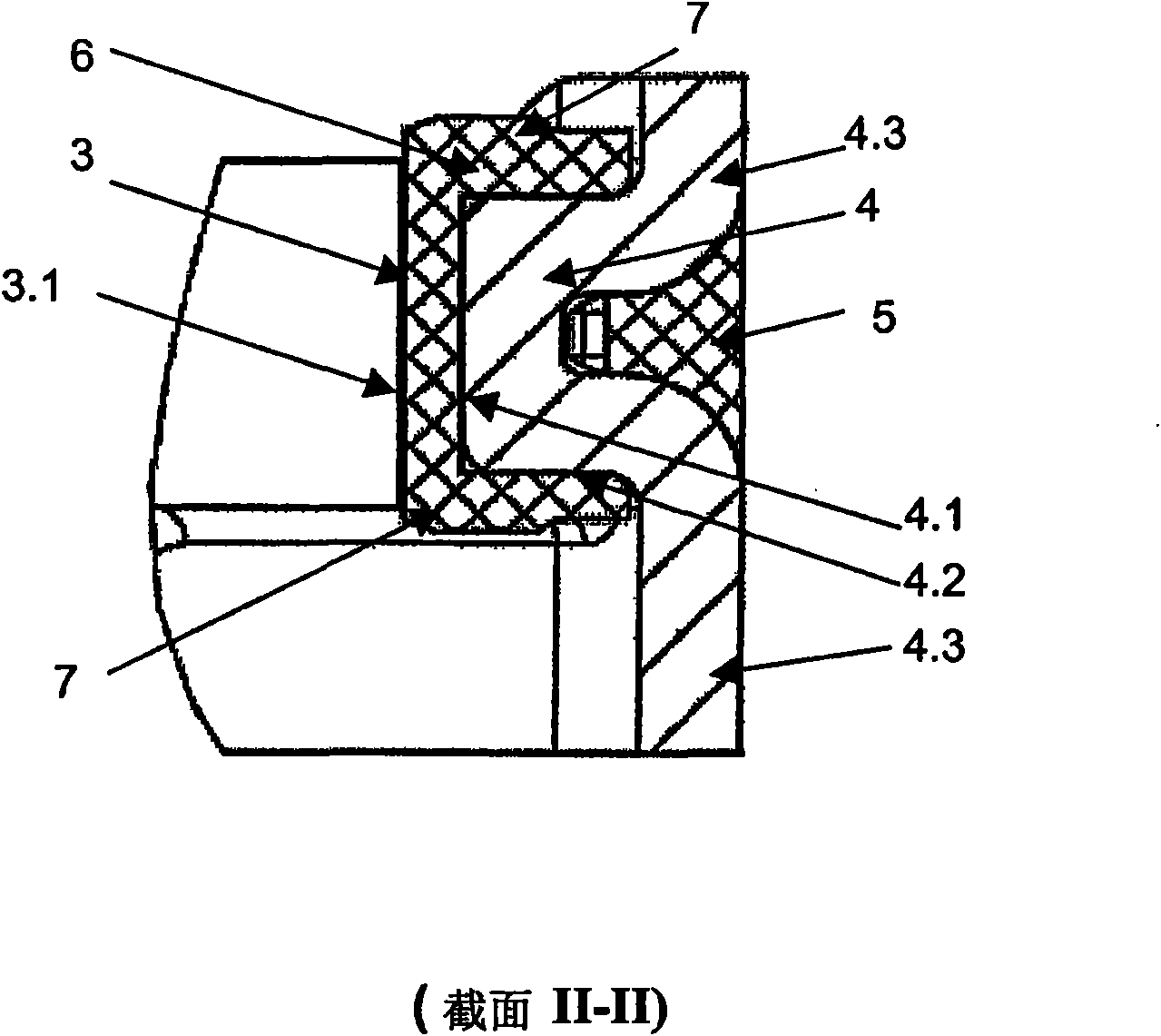

[0037] figure 2 show figure 1 Plan view of the section II-II of the selector fork 2 with fastening section A. At least in this fastening section A, the arm 4 of the selector fork 2 is formed in the shape of a sheet metal. This means that the length extension of the material of the arm 4 is designed to be greater than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com