Double-sheet side guard plate for inner side of joint of two vehicles or compartments

A connection, two-piece technology, applied in the direction of railway car body, railway car body parts, material-based railway technology, etc., can solve the problems of complex structure, expensive price and expensive materials of the inner wall guard plate, and achieve simple structure, Low cost and the effect of protecting the safety of passengers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

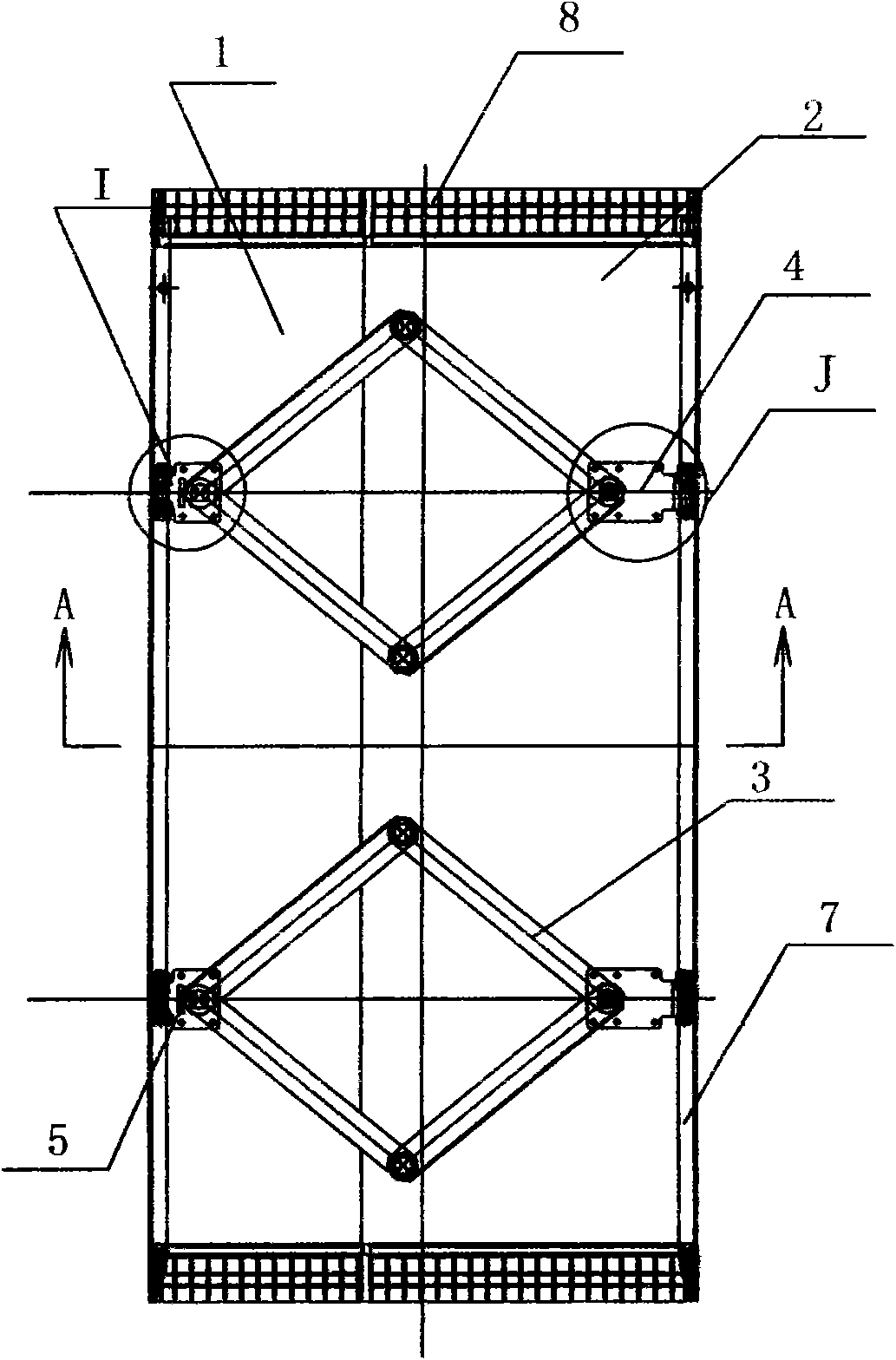

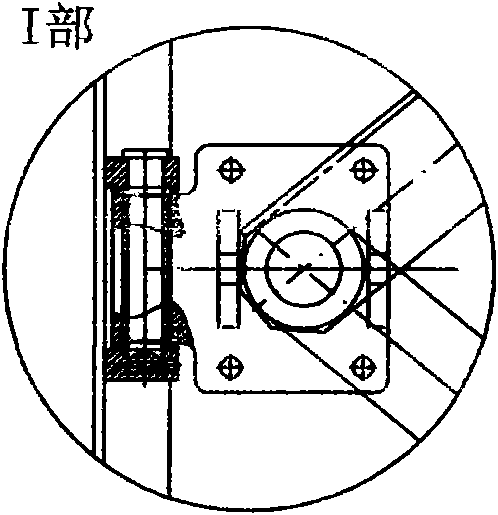

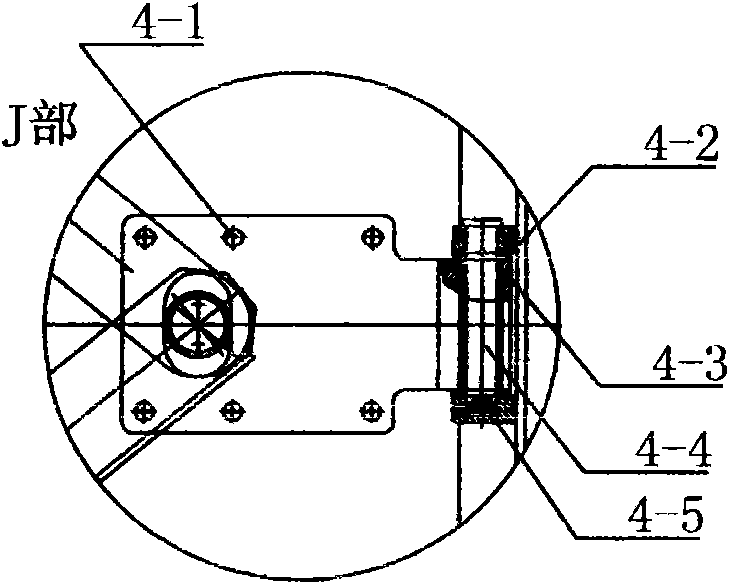

[0010] refer to Figure 1-5 , the specific embodiment adopts the following technical scheme: it is made up of two guard plates 1, 2, connecting rod mechanism 3, hinge mechanism 4, 5, support block 6, mounting frame 7 and elastic cover plate 8, guard plate 1, 2 are overlapped with each other and arranged on the mounting frame 7, the link mechanism 3 is connected with the hinge mechanisms 4, 5 and the support block 6, the hinge mechanisms 4, 5 are respectively connected with the mounting frame 7, and the elastic cover plate 8 is set on the guard plate 1 , 2 both ends. The link mechanism 3 can realize stretching, compression and longitudinal displacement; the hinge mechanism 4 can realize the swing of the guard plate 1 along the vertical axis; the hinge mechanism 5 can realize the swing of the guard plate 2 along the vertical axis and within a certain range along the horizontal axis. Rotate; the support block 6 makes the guard plate as a whole bear the pressure from the outside....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com