Pressurizing locking die and slideway type die opening and closing device for two-template injection molding machine

A technology for opening and closing molds and injection molding machines, which is applied in the field of plastic machinery. It can solve problems such as high energy consumption, stuck movable templates, and increased production costs, and achieves balanced mold opening and closing, large clamping force, and reliable clamping force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

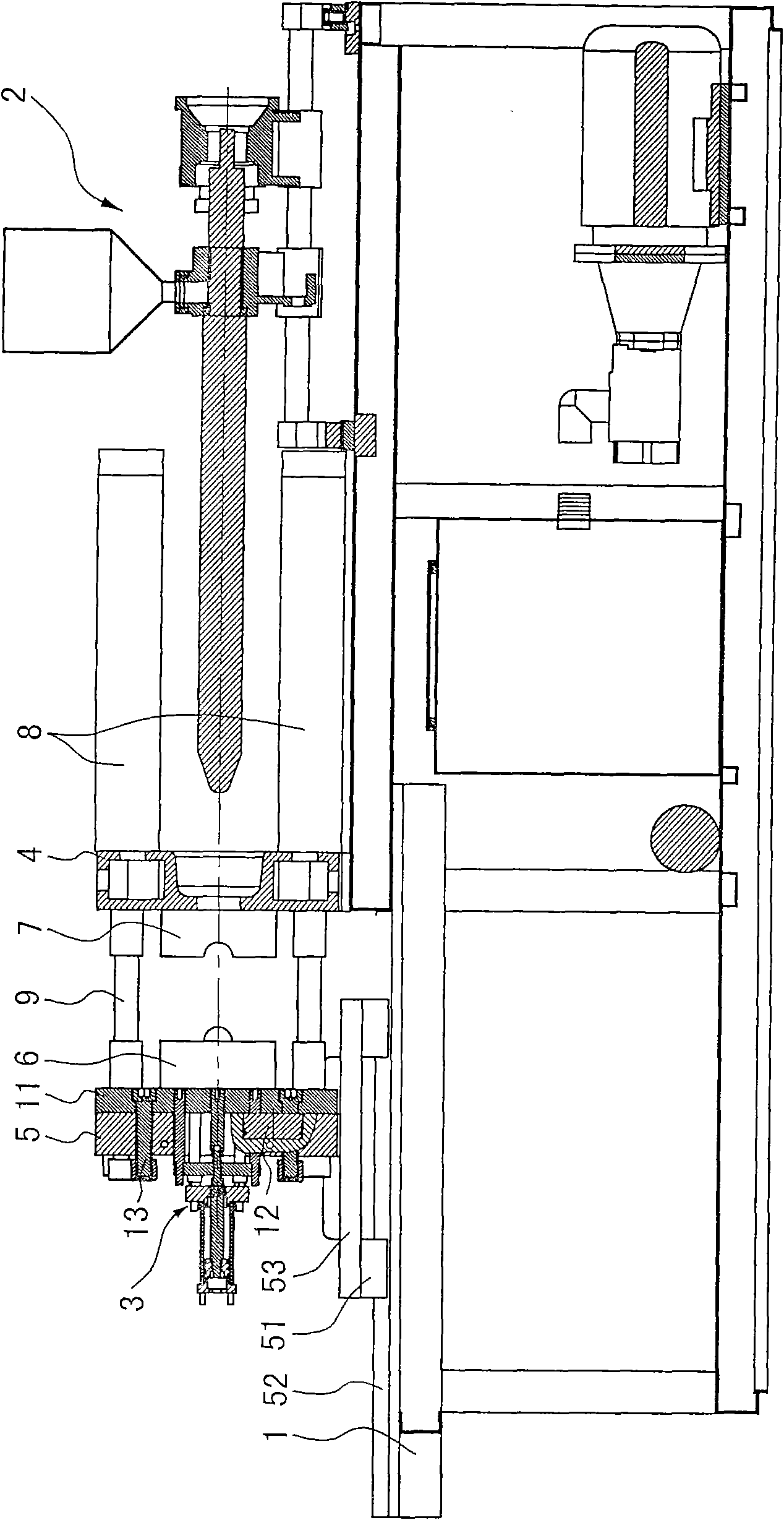

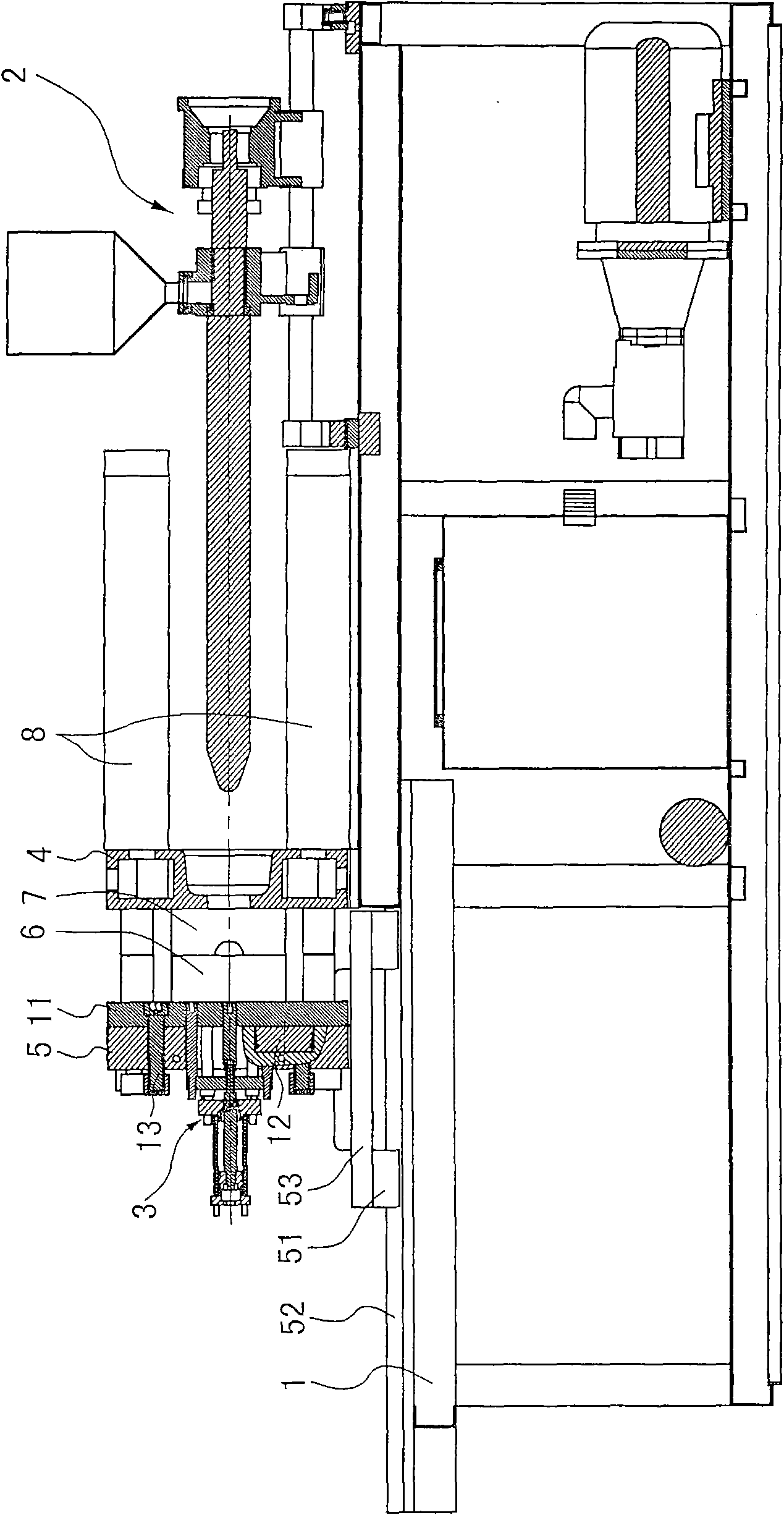

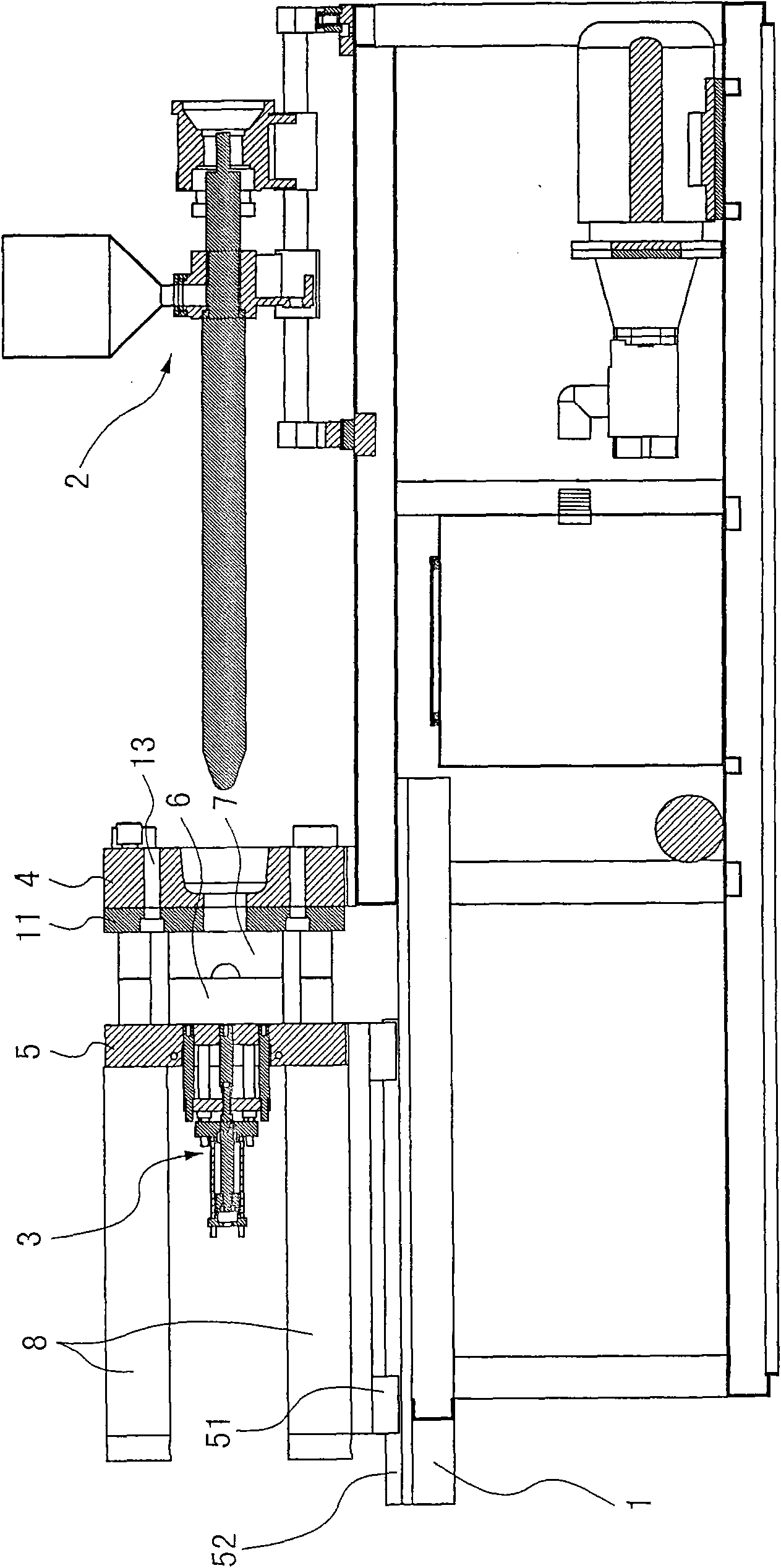

[0011] The invention relates to a pressurized mold clamping and slide rail type mold opening and closing device for a two-platen injection molding machine, such as Figure 1-Figure 4 Shown, comprise frame 1, injection device 2, mold opening and closing device, mold clamping device and ejector device 3 are installed on the frame, described mold opening and closing device comprises fixed template 4 and movable template 5, respectively in each template The molds 7 and 6 are installed, and the opening and closing mold cylinder 8 is symmetrically installed on one of the two templates with the center of the template, and the opening and closing mold cylinder 8 piston rod 9 is connected to the other template in the two templates, which is characterized in that Slide block 51 is installed at the bottom of movable formwork 5, and slide rail 52 is installed on frame 1, and slide block 51 cooperates with slide rail 52, and described clamping device comprises the booster plate 11 that is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com