Clamping mechanism

A technology of clamping mechanism and clamping block, which is applied in the direction of chuck, manipulator, drilling equipment, etc., can solve the problems of narrow pipe diameter range, insufficient clamping force, insufficient strength, etc., and achieve improved stress state, simple structure, The effect of small bending moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

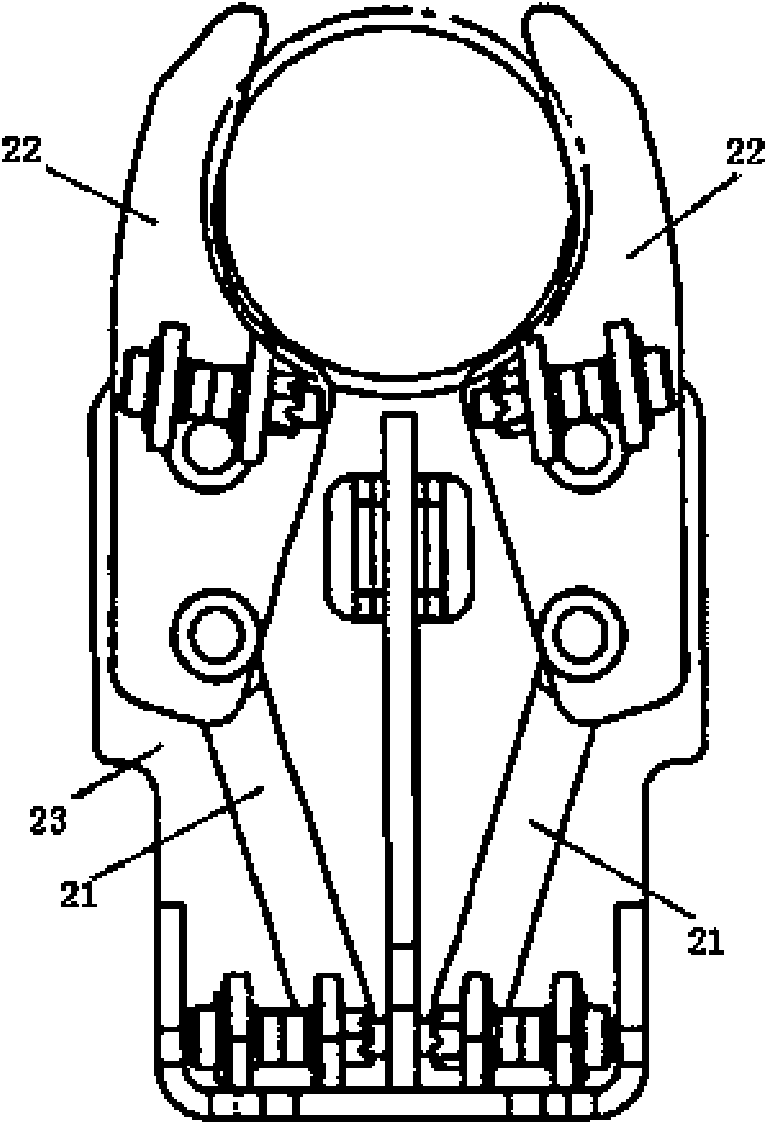

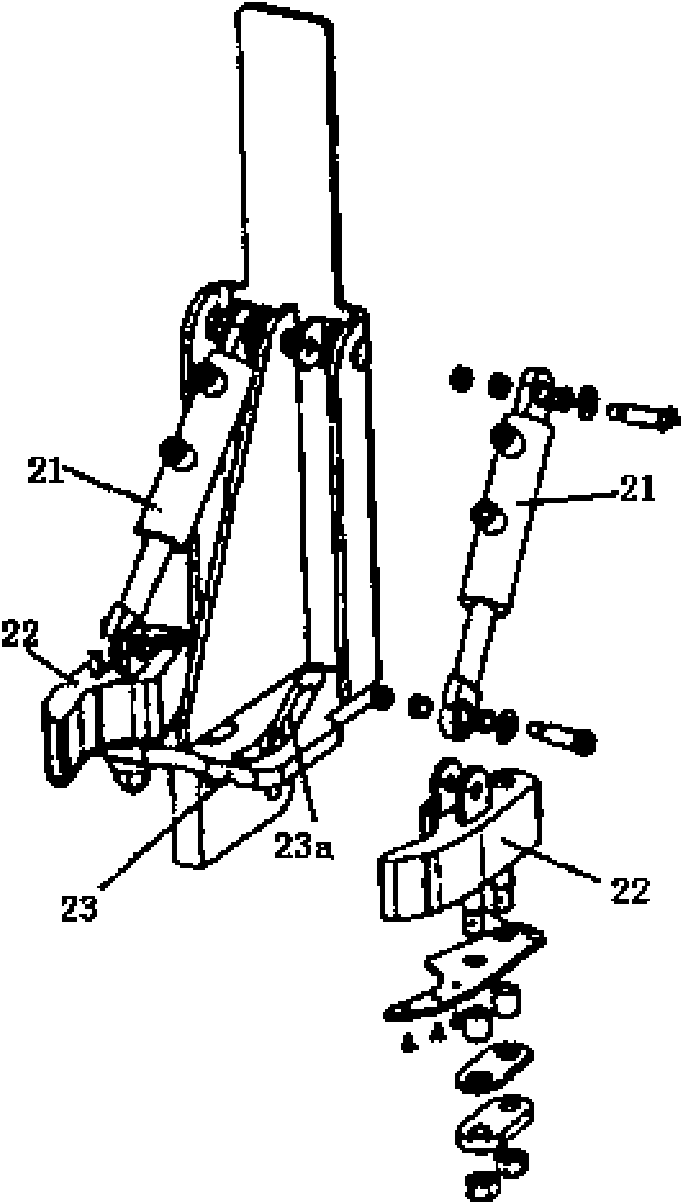

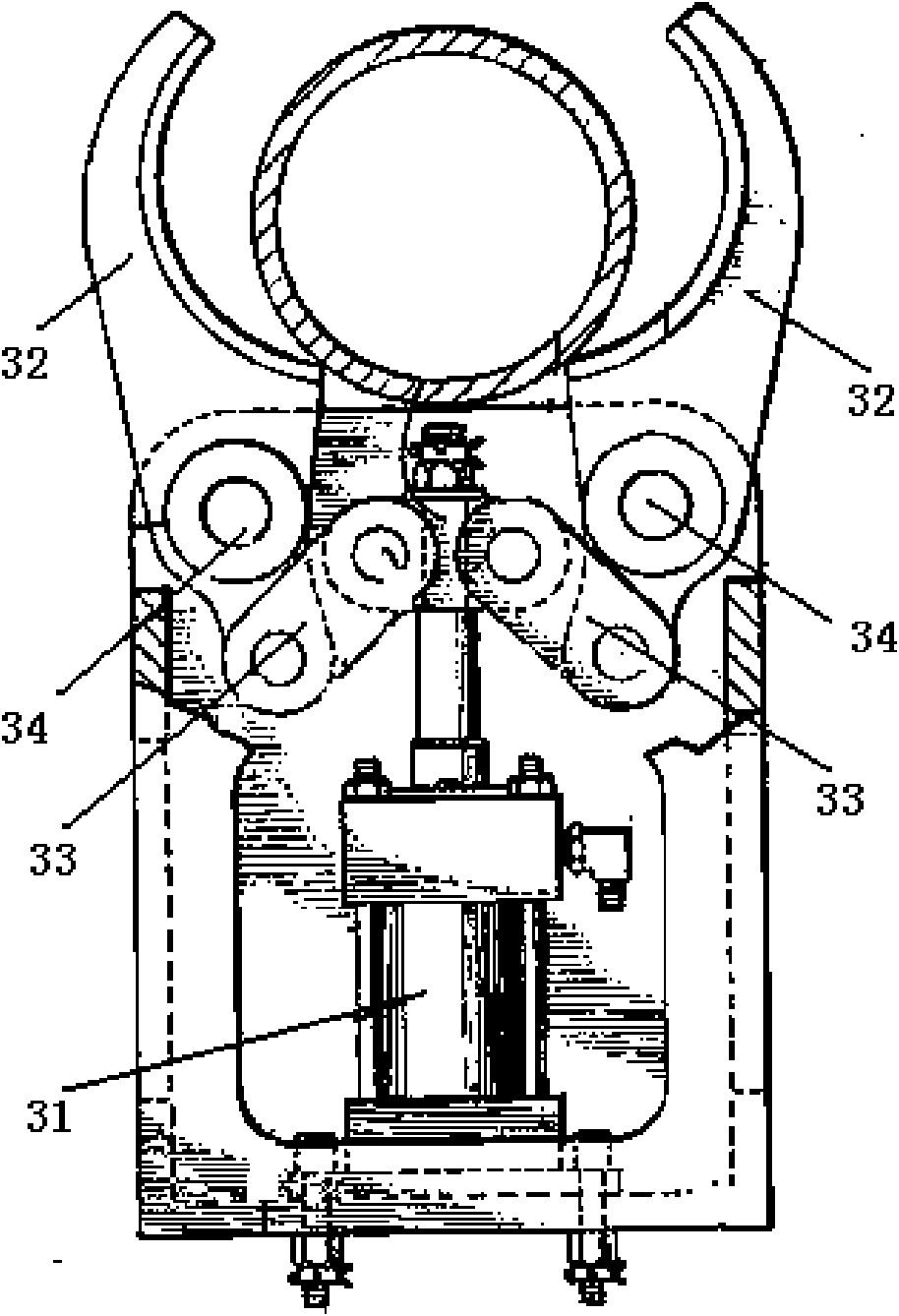

[0033] Such as Figure 4 to Figure 6 As shown, a clamping mechanism mainly consists of a housing 1, an oil cylinder 2 clamping block 3, a connecting plate 4, a fixed block 5, a first tooth plate 6, a second tooth plate 7, a pulley 8 and pins. Wherein, the housing 1 is welded by two cover plates 11 on the upper and lower ends, two side plates 12 on the left and right sides, and a bottom plate 13. The two cover plates 11 and the two side plates 12 are symmetrically arranged respectively, and the two side plates 12 are shorter than The two cover plates 11 form openings on both sides of the front portion of the two cover plates 11, the bottom plate 13 closes the rear end of the housing 1, and two ear plates 14 with hinged holes are fixed on the outer surface of the bottom plate 13. Housing 1 is equipped with an oil cylinder 2, the cylinder barrel of oil cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com