Cylindrical backwash purifying device

A purification device and backwashing technology, which is applied to chemical instruments and methods, fixed filter element filters, filtration separation, etc., can solve the problems of low filtration efficiency, small filtration area, and small effective filtration area, so as to improve work efficiency, The effect of increasing the filtration area and ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

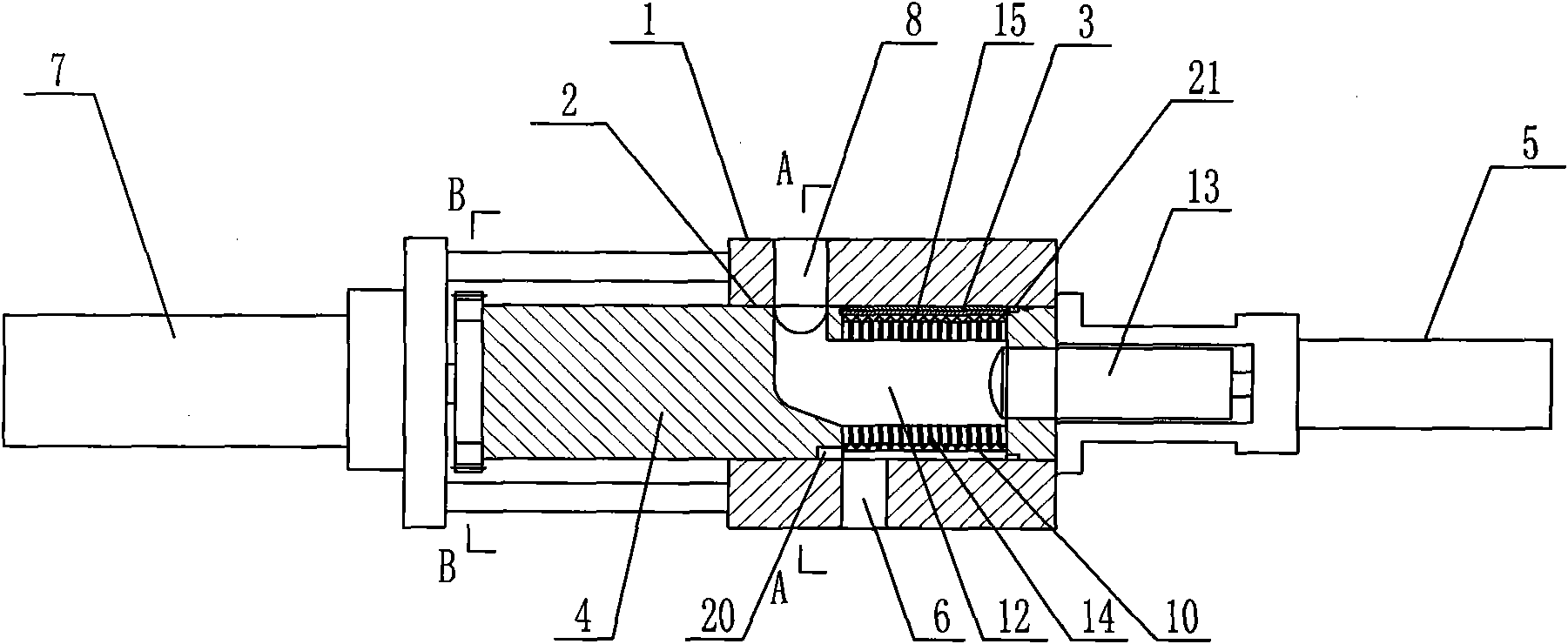

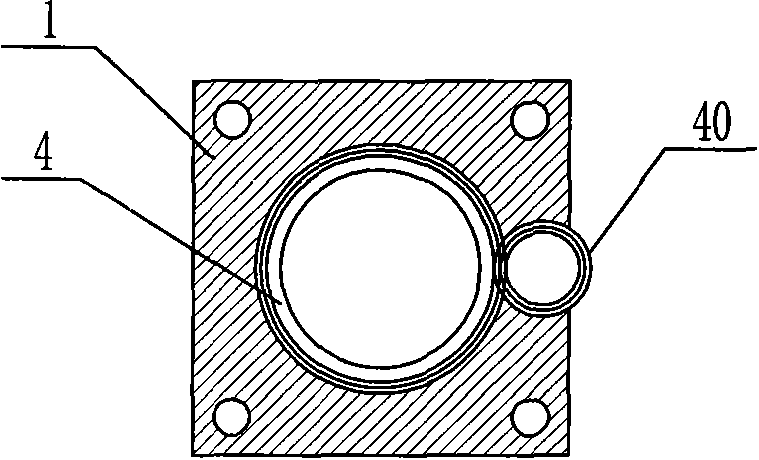

[0026] Such as figure 1 , figure 2 As shown, the cylindrical backwash purification device of the present invention includes a main body 1, a cylindrical through hole 2 is arranged in parallel in the main body 1, and a plunger 4 that is closely matched with it and can be axially slidably connected is arranged in the through hole 2 , the length of the plunger 4 is greater than the length of the through hole 2, and the front and rear of the main body 1 are respectively provided with a feed channel 6 and a discharge channel 8 connected with the through hole 2. The outer circle of the front part of the plunger 4 is concave inward and forms an annular cavity 10 with the inner wall of the through hole 2 respectively. The annular cavity 10 is connected with the feed channel 6. An "L"-shaped hole 12 connected to the discharge channel 8, in the "L"-shaped hole 12, a piston 13 slidingly connected to it is provided in front of the annular cavity 11, the piston 13 protrudes from the plun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com