Engine oil purifying device for removing volatile contaminants from engine oil

A technology for volatile pollutants and purification devices, which is used in engine lubrication, evaporation, mechanical equipment, etc., can solve problems such as poor installation adaptability and high requirements for installation angles of purification devices, achieve efficient operation, and increase the surface area of evaporation film formation. , the effect of improving evaporation/distillation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

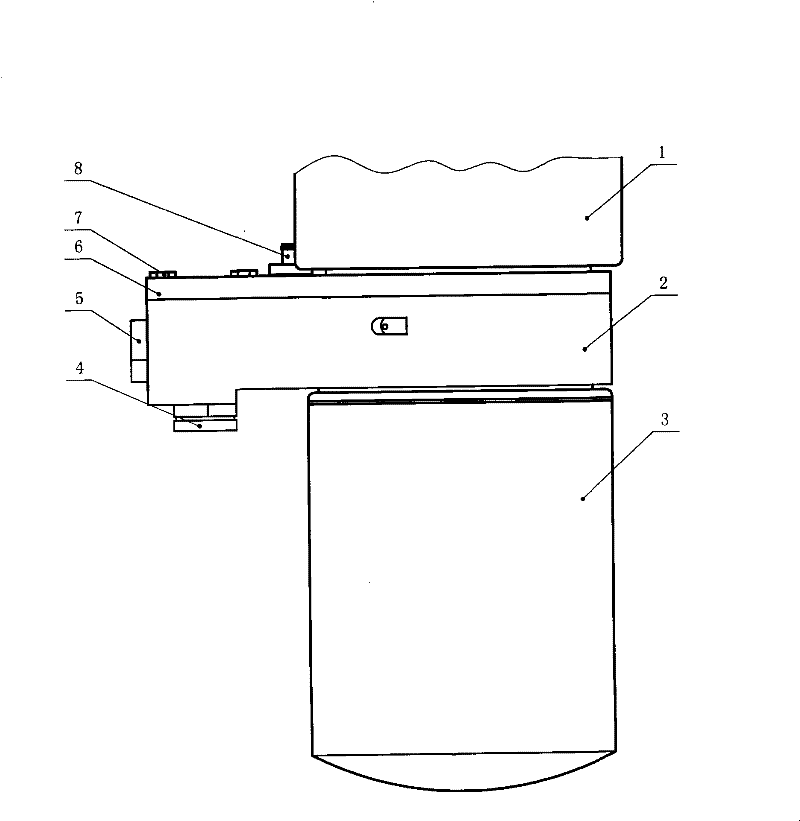

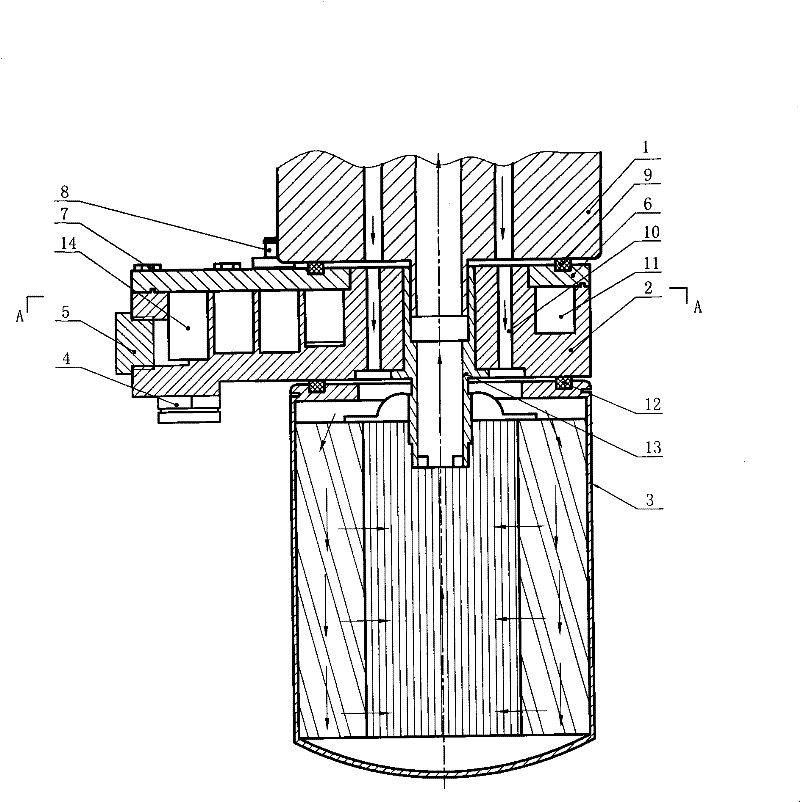

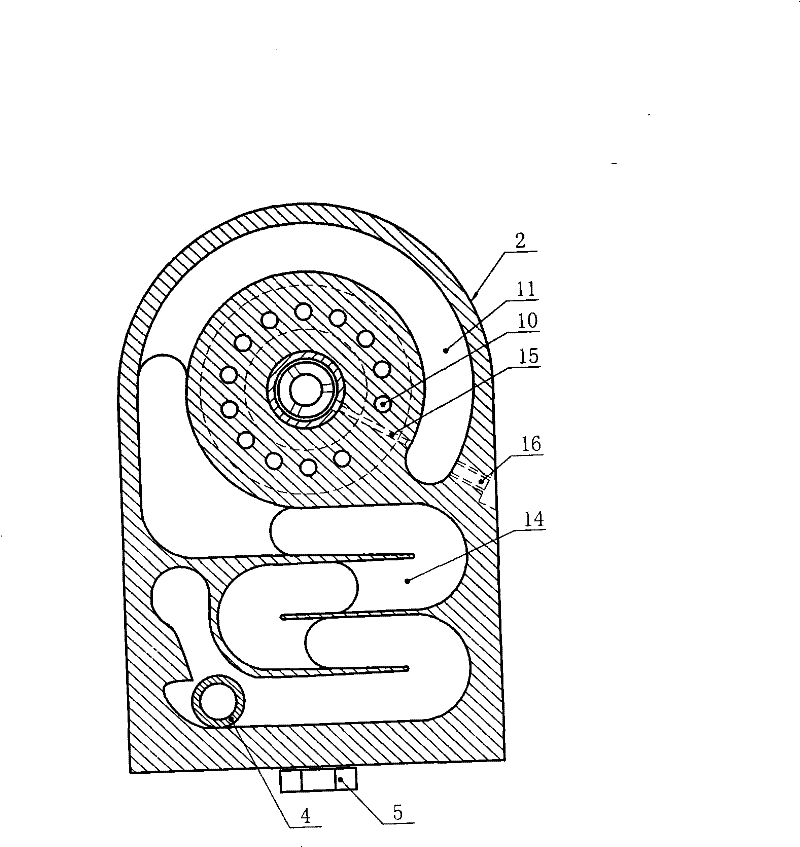

[0024] An engine oil purification device for removing volatile pollutants in engine oil is composed of an evaporation tank 2 , an end cover 6 and a connecting pipe 13 . The evaporator is made with an axial center flow hole, and a connecting pipe for connecting the liquid source 1 and the filter 3 to both sides of the evaporator is inserted in the center flow hole, and a set of Bypass flow holes 10 . The evaporating tank is made with an annular groove type evaporation chamber 11 having a starting end and an ending end, and an end cover is sealed on the annular groove type evaporation chamber. A through microhole 15 is radially formed on the connecting pipe between the central flow hole and the evaporating chamber and the ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com