Maxillary bone repair stent and manufacturing method thereof

A manufacturing method and jawbone technology, applied in bone implants, medical science, prostheses, etc., can solve the problems of inability to achieve large-area maxillary defect shape and function repair, application limitations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

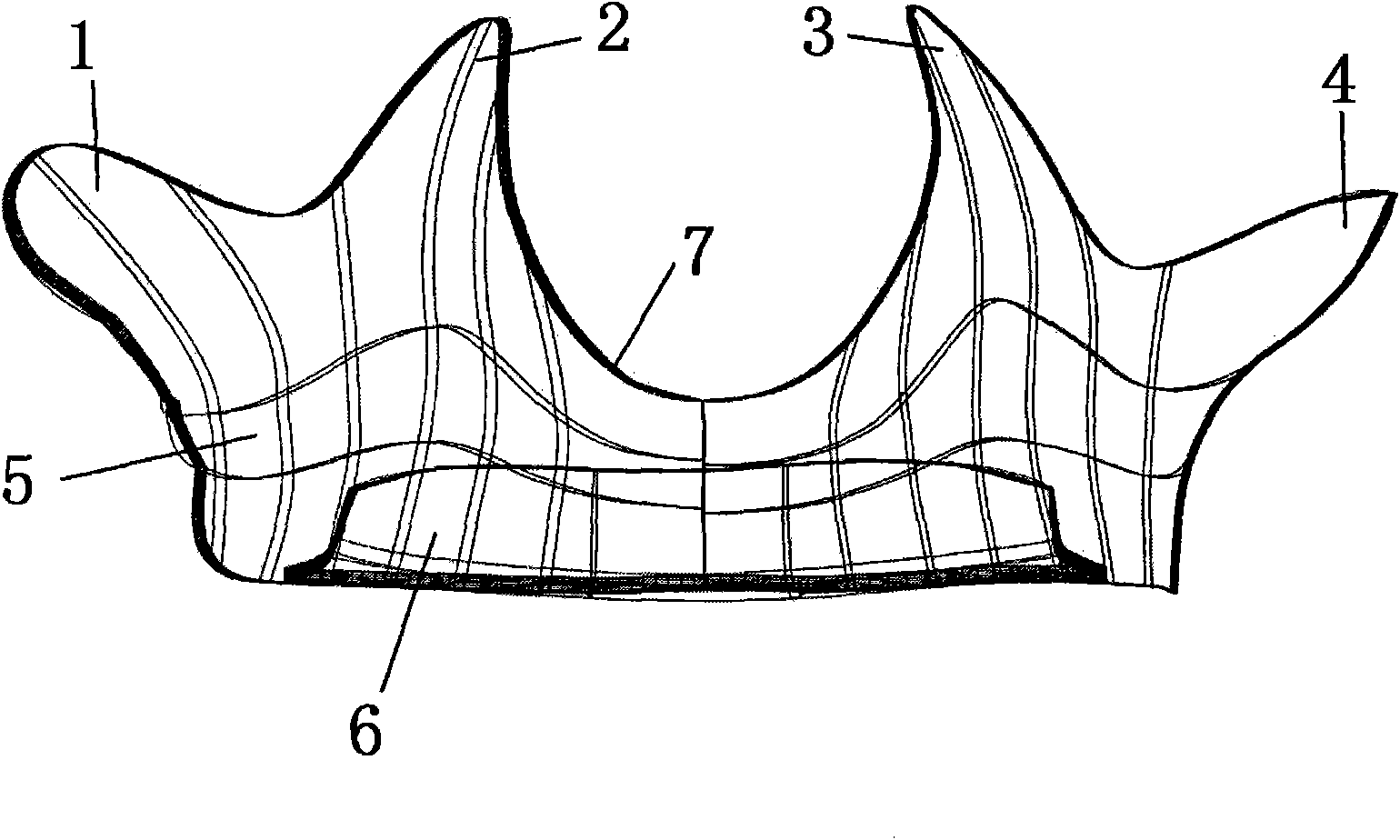

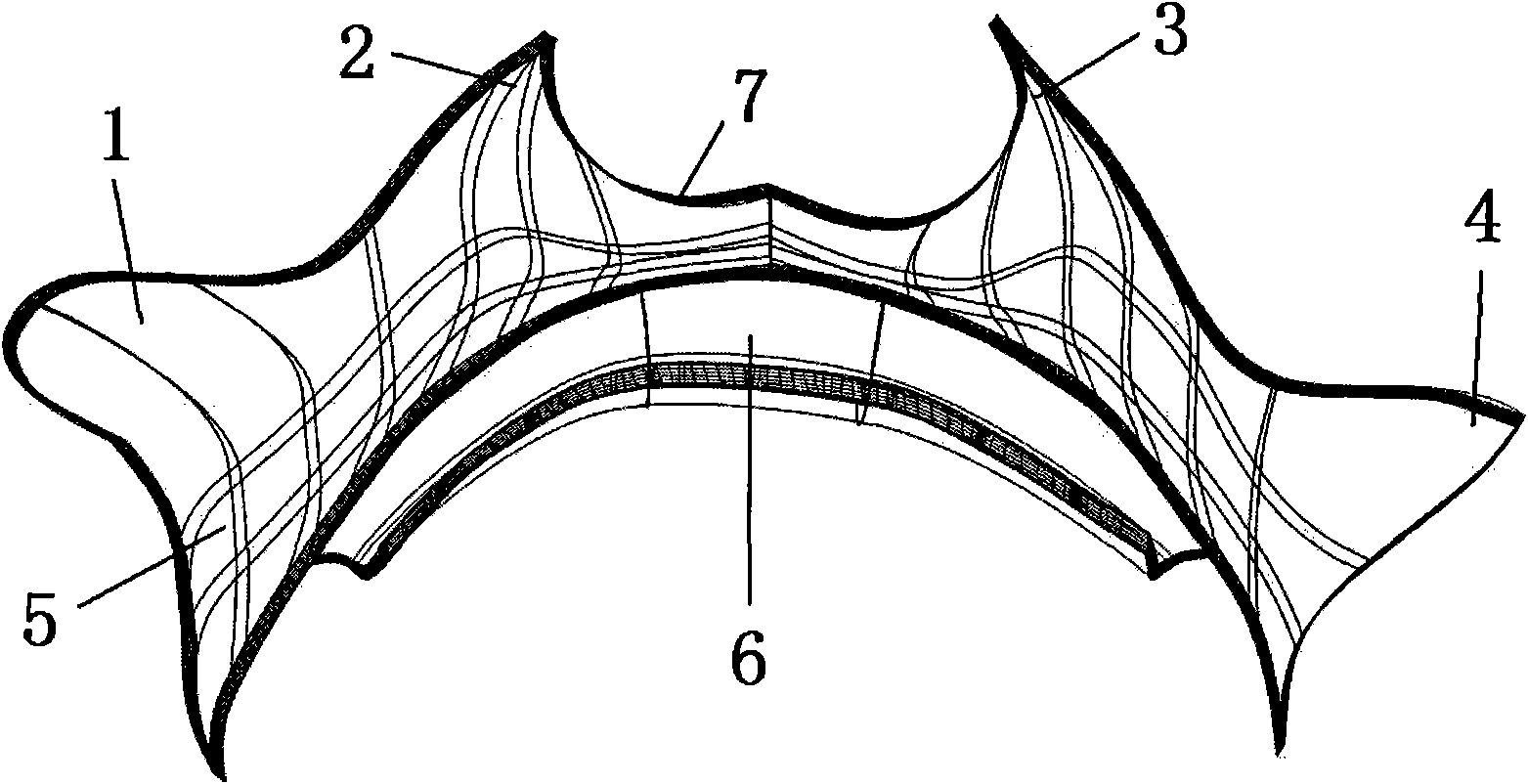

[0029] Below in conjunction with the attached drawings ( Figure 1-Figure 3 ) Describe the present invention.

[0030] figure 1 It is a schematic diagram of the structure of the maxillary repair bracket of the present invention, figure 2 Yes figure 1 Top view. Such as figure 1 with figure 2 As shown, the maxillary repair stent includes a maxillary-shaped stent body. On the upper edge of the maxillary-shaped stent body, four protruding connection areas each with a counterbore array structure are sequentially distributed: the right zygomatic connection area 1. Right pear-shaped hole connecting area 2, left pear-shaped hole connecting area 3, and left cheekbone connecting area 4; between the right pear-shaped hole connecting area 2 and left pear-shaped hole connecting area 3 Between the pear-shaped hole shape restoration area 7; on the lower edge of the maxillary stent body is distributed a maxillary bone graft area 6; between the upper and lower edges of the maxillary stent body...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com