Integrated hydraulically-driven permanent magnet synchronous generator

A permanent magnet synchronous and integrated technology, applied in variable displacement engines, reciprocating piston engines, machines/engines, etc., can solve problems such as external leakage, large weight and space occupation, and unsatisfactory control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

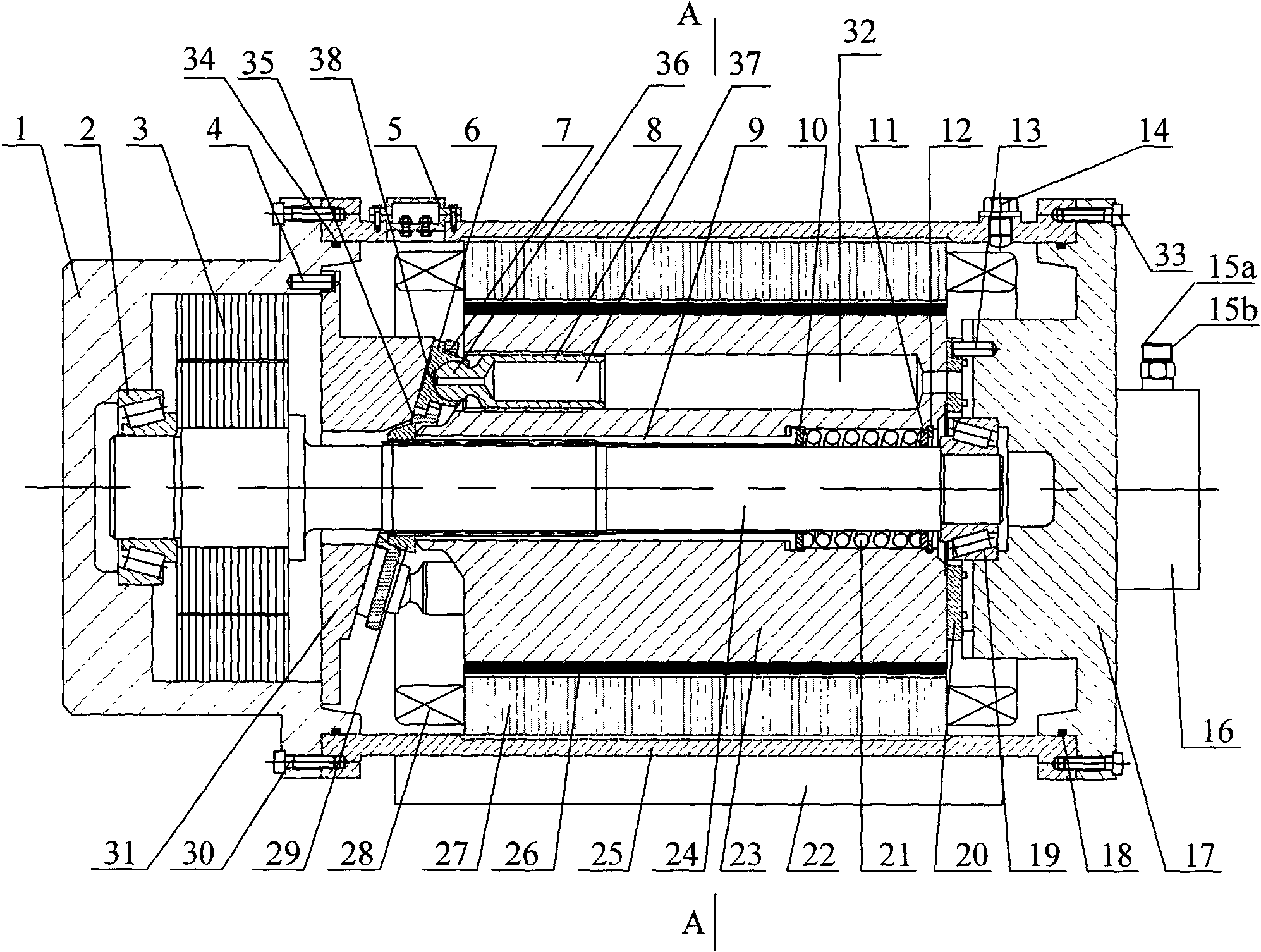

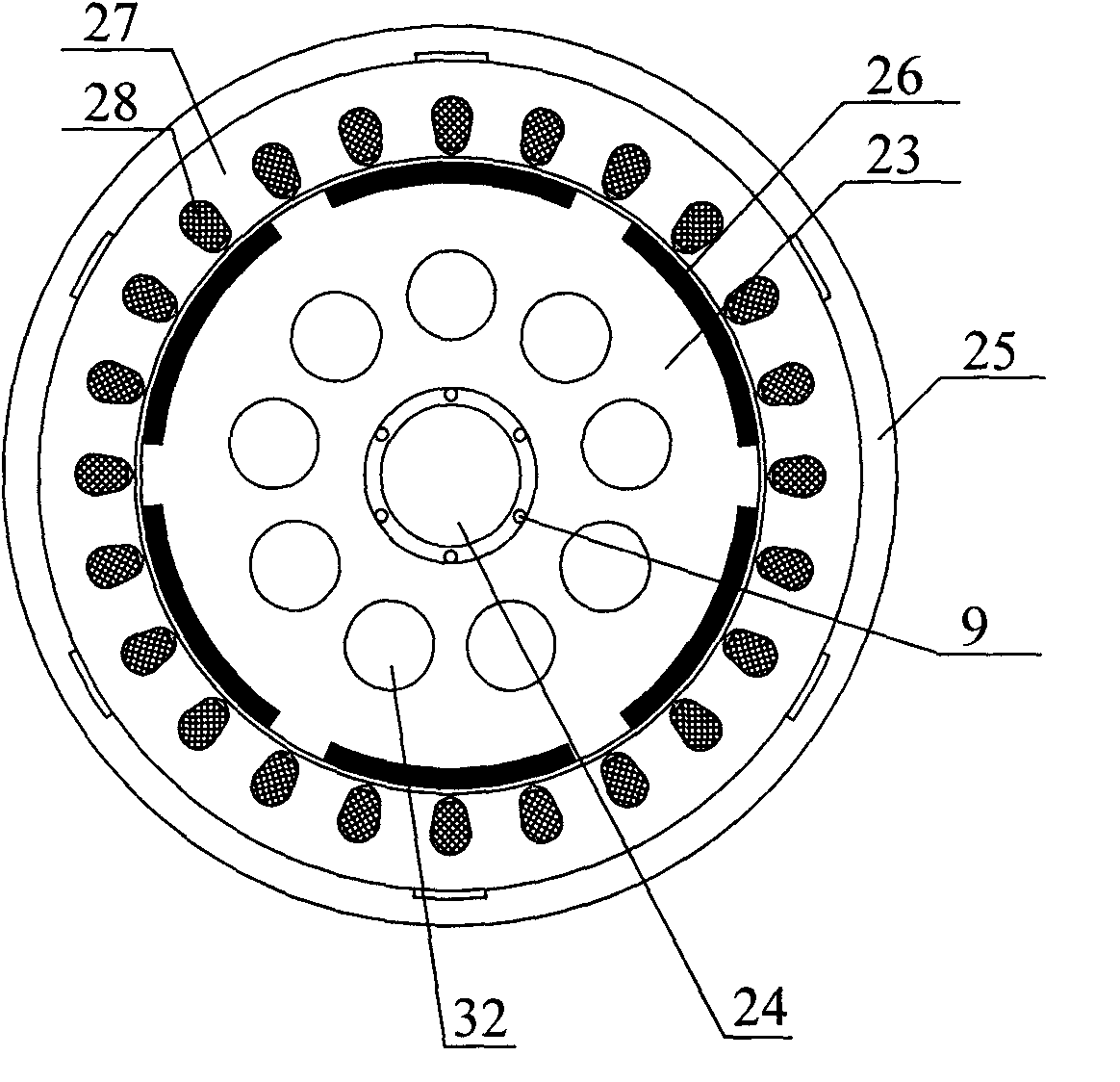

[0017] Figure 1 ~ Figure 2 In combination, an integrated hydraulically driven permanent magnet synchronous generator is provided, including a base 22 and a motor housing 25 arranged on the base 22, and the left end cover 1 and the motor housing 25 are respectively fixed on both sides. Right end cover 17; cylinder body 23, rotating shaft 24, swash plate 31, oil distribution plate 20, etc. are respectively provided in motor housing 25. A junction box 5 is provided on the motor housing 25 , and an oil drain port 14 is also provided on the motor housing 25 .

[0018] The left end cover 1 is fixedly connected with the motor housing 25 through screws 30, and a sealing ring 34 is arranged between the left end cover 1 and the motor housing 25; the right end cover 17 is fixedly connected with the motor housing 25 through screws 33, and the right end cover A sealing ring 18 is arranged between 17 and the motor housing 25 . An oil inlet passage and an oil outlet passage are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com