Ex-situ component recovery

An ex-situ, component technology, used in electrical components, semiconductor/solid-state device manufacturing, thin material processing, etc., can solve problems such as processing equipment not being available for manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

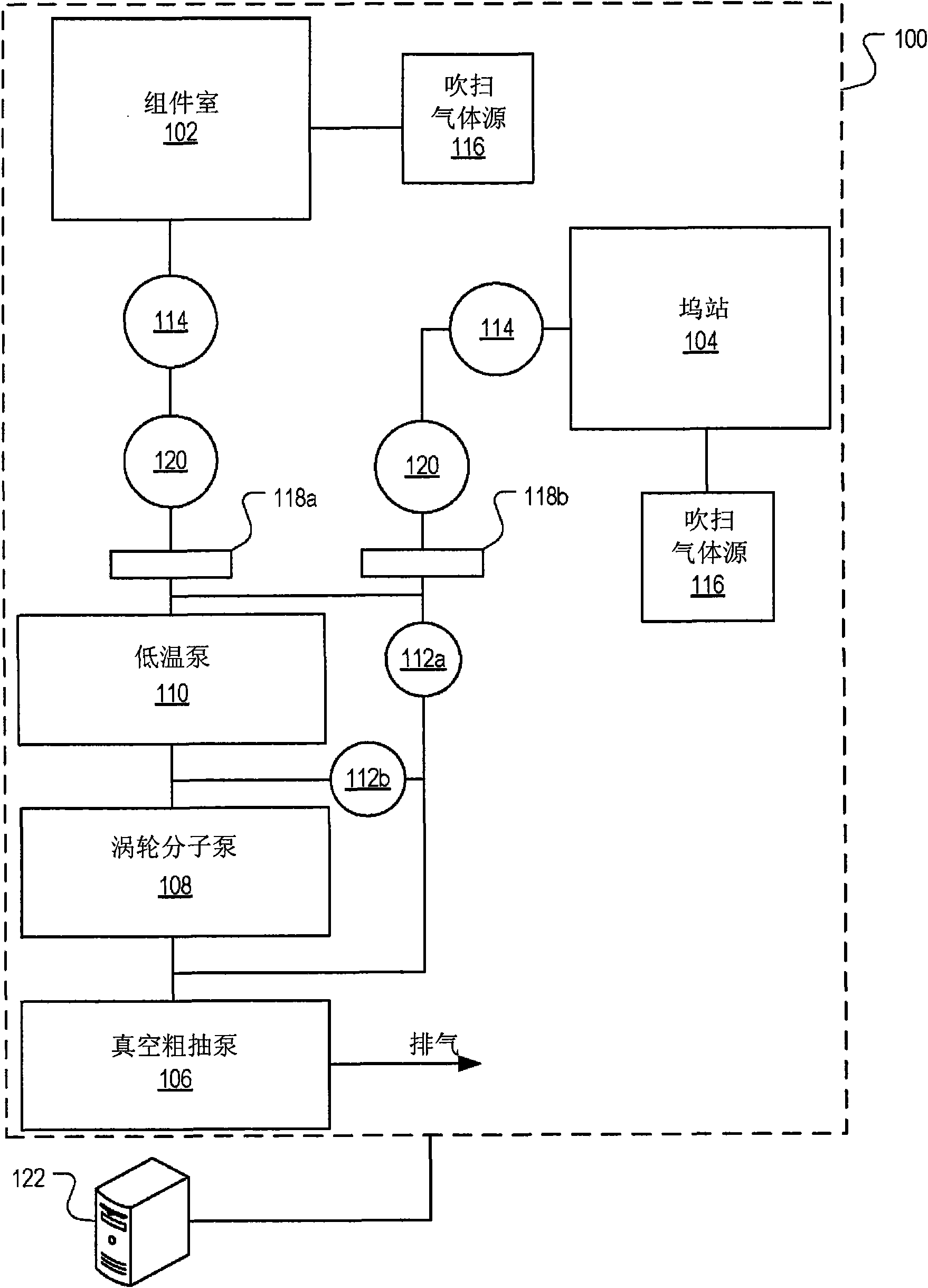

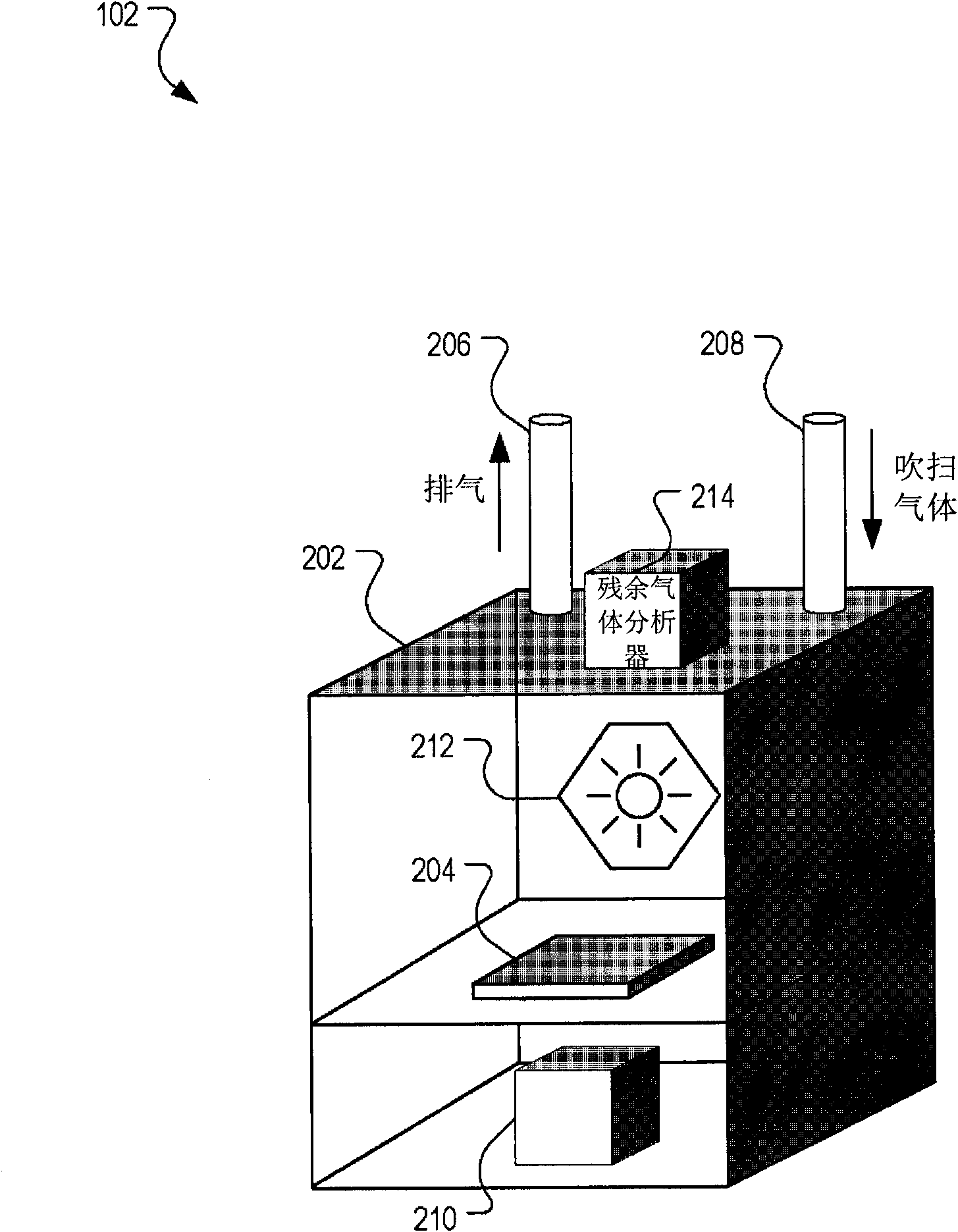

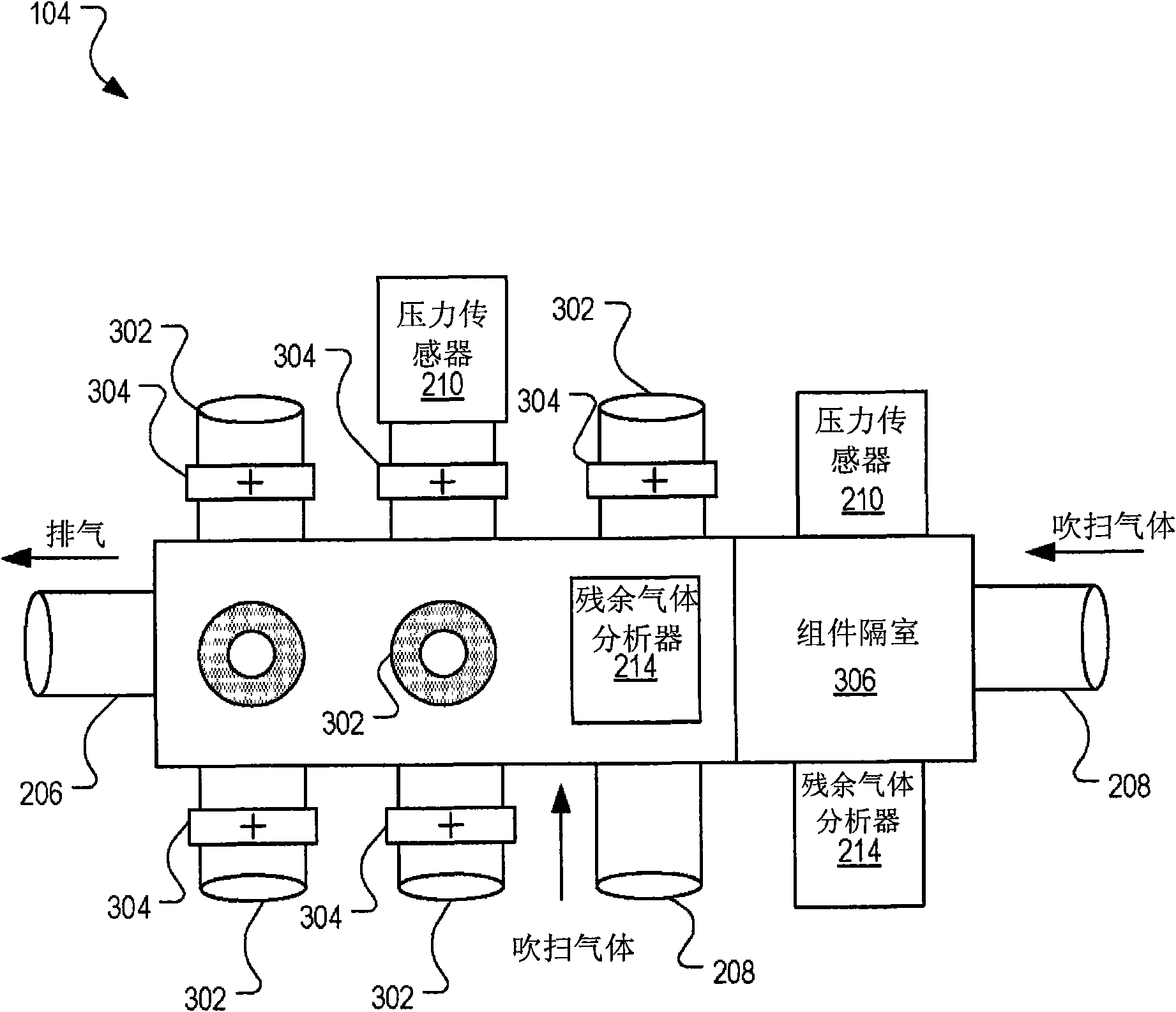

[0012] Manufacturing throughput can be increased by performing ex situ recovery of processing system components. Ex situ recovery may be performed by desorbing, degassing, or removing contaminants (eg, moisture, oxygen, air, etc.) from components of the treatment system in the recovery system. In certain embodiments, the recovery system can be independent of (eg, separate from) the treatment system itself. The recovery system may include a docking station and / or a heated vacuum chamber. The heated vacuum chamber may be used to desorb or degas components that may be located, for example, inside a processing system, such as a turntable, while the docking station may be used to desorb components that may be connected to, for example, a processing system (e.g. valves) for desorption or degassing. Treatment system components may be placed under pressure by a recovery system to desorb or degas contaminants and remove false leaks (eg, physically trapped contaminants). The recovery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com