Processing method of equipment vibration signal

A technology of vibration signal and processing method, which is applied in the direction of machine gear/transmission mechanism testing, measuring devices, instruments, etc., can solve the problems of affecting the accuracy of hidden troubles of diagnostic equipment, difficult to implement, and cannot be obtained at the same time, and achieves effective wavelet transform realization. Method, frequency component accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiment of the method for processing the vibration signal of the equipment of the present invention. This embodiment is used to process the vibration signal of the low-speed and heavy-duty gearbox under variable working conditions. This embodiment includes the following steps:

[0024] Step (1), the step of measuring the vibration signal of the equipment, specifically:

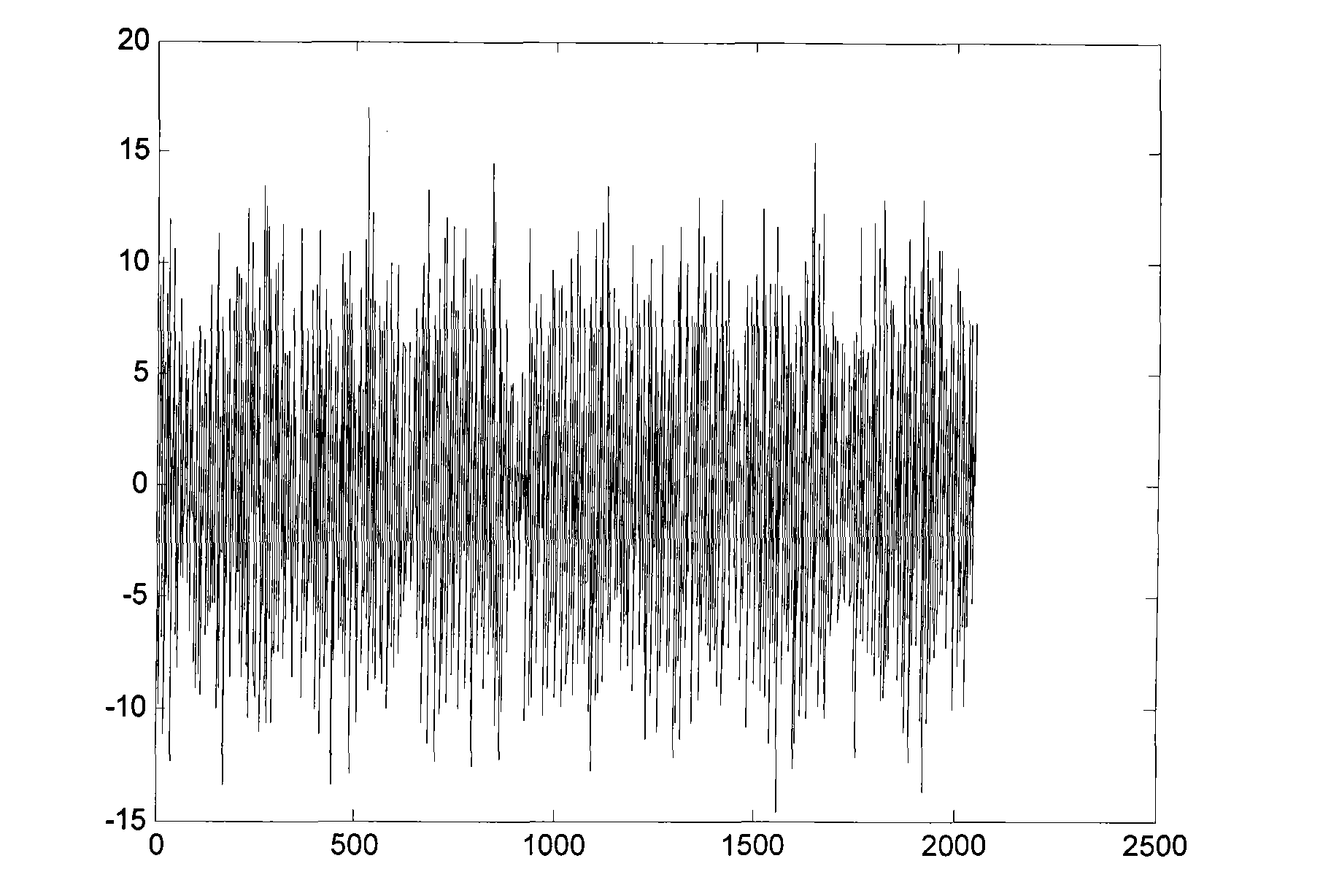

[0025] Fix the SRI50 acoustic emission on the casing of the gearbox. The position of the acoustic emission is as close as possible to the main bearing of the gearbox. The output of the acoustic emission is input to the computer through A / D conversion, and the sampling frequency is f s is 1000Hz, the time-domain waveform of the vibration signal obtained by the computer is as follows figure 1 As shown, the time-domain waveform cannot be directly used to diagnose potential equipment failures.

[0026] Step (2), the step of processing the equipment vibration signal, specifically:

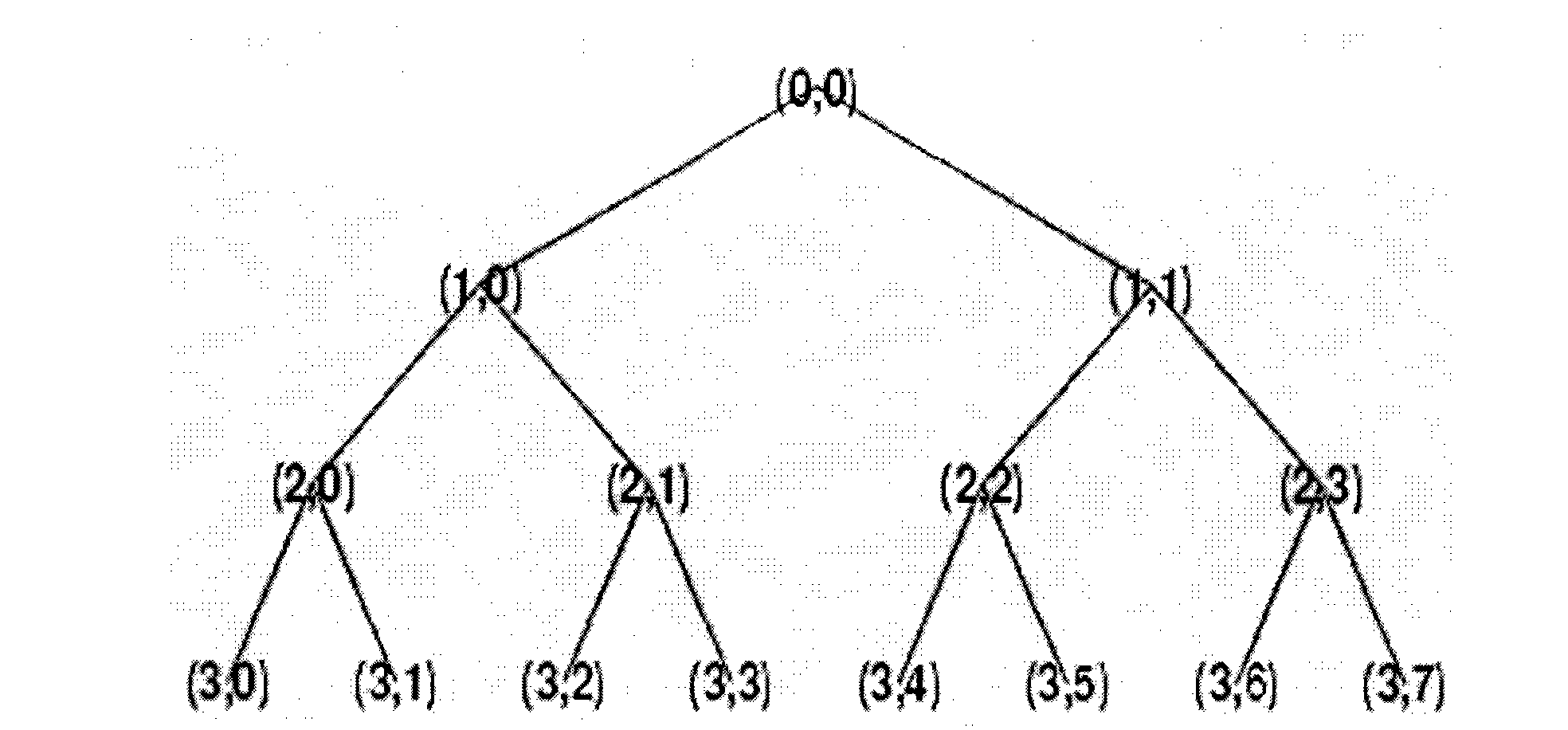

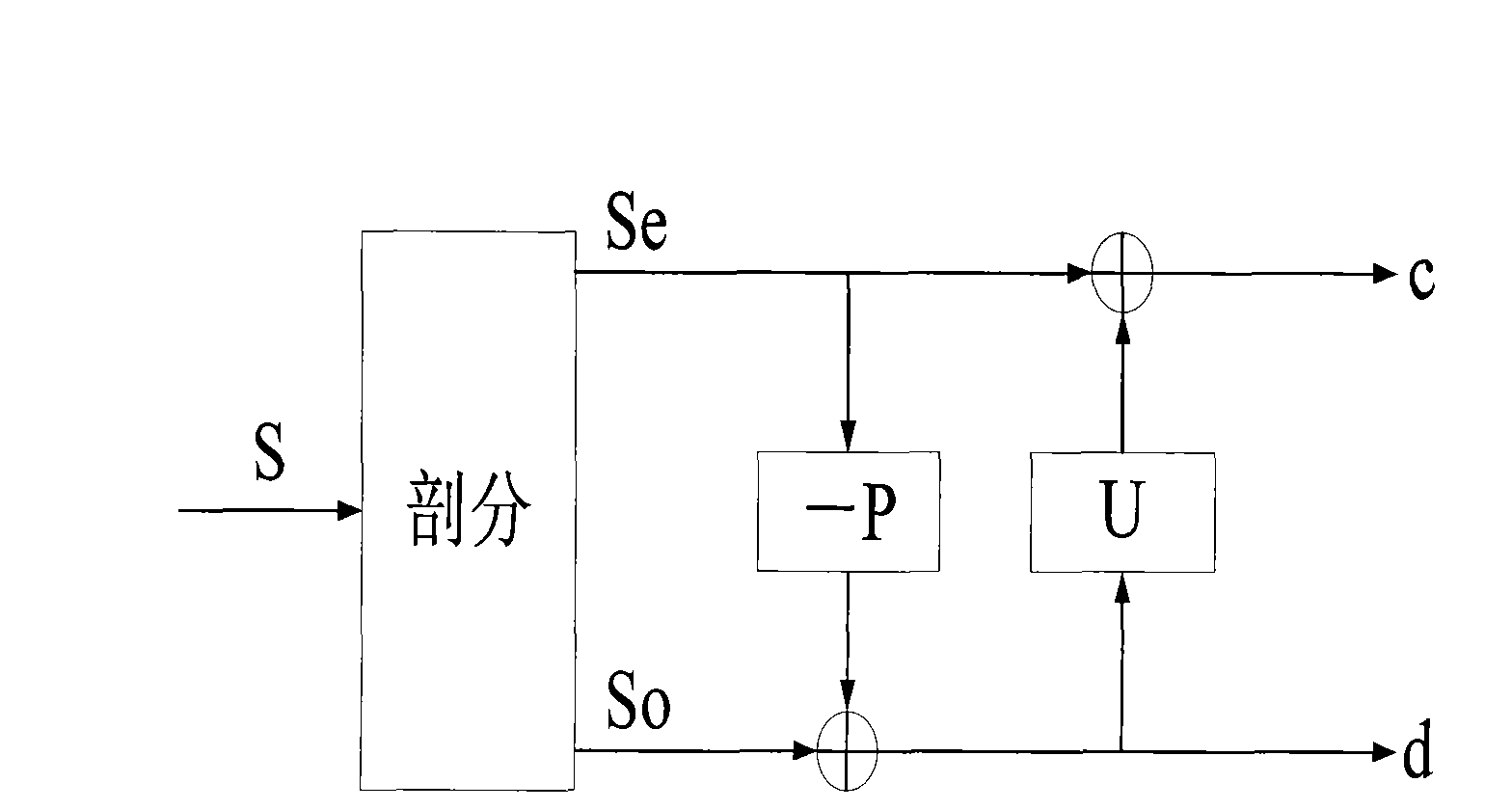

[0027] Step (2.1), d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com