Self-falling self-producing coal-mining method suitable for coal bed at inclined angle over 45 degrees

A coal seam and self-falling technology, applied in surface mining, earth-moving mining, underground mining, etc., can solve problems such as low efficiency, hidden dangers, high workload and difficulty in digging wells, and achieve the effect of good safety and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

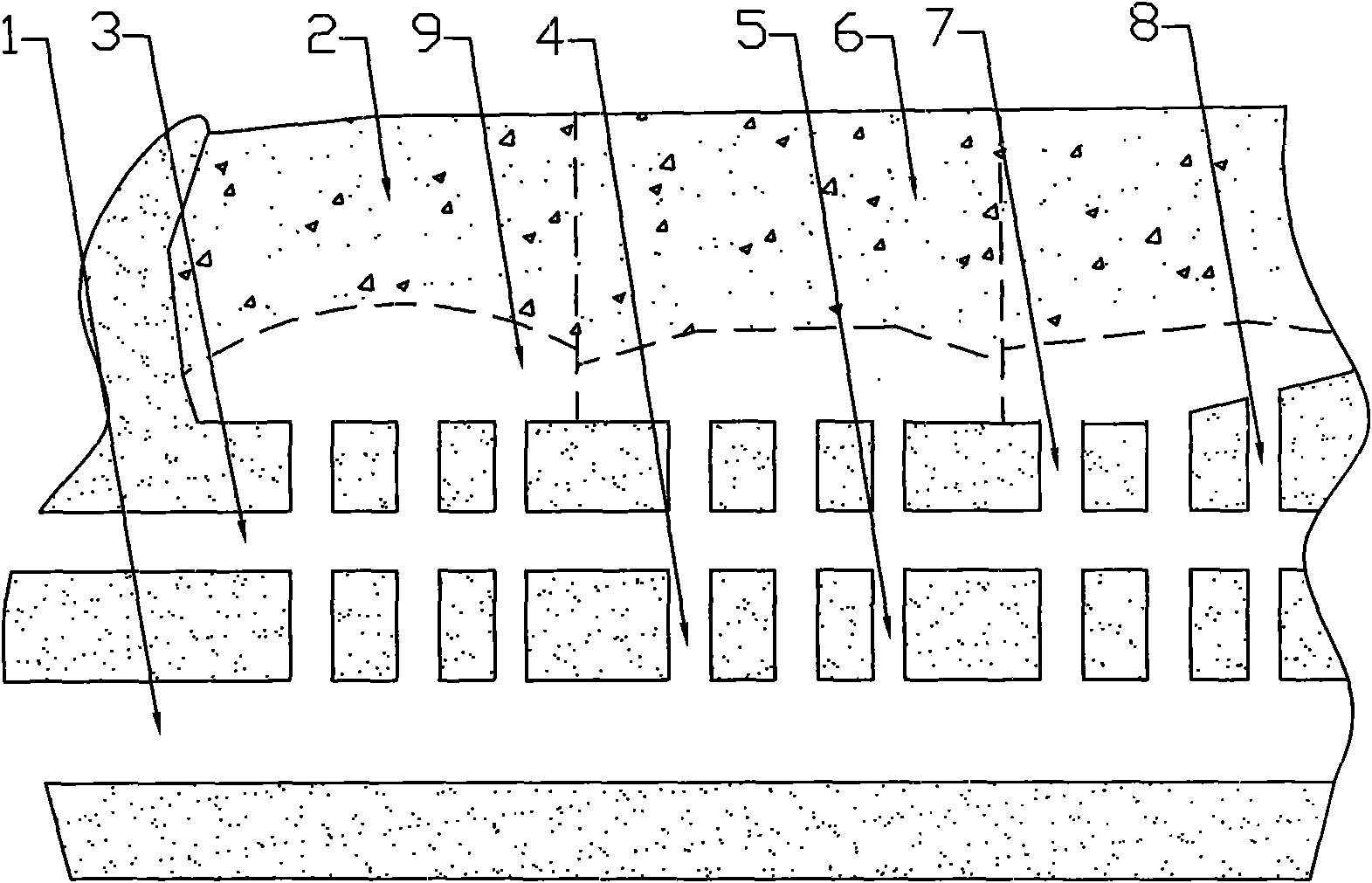

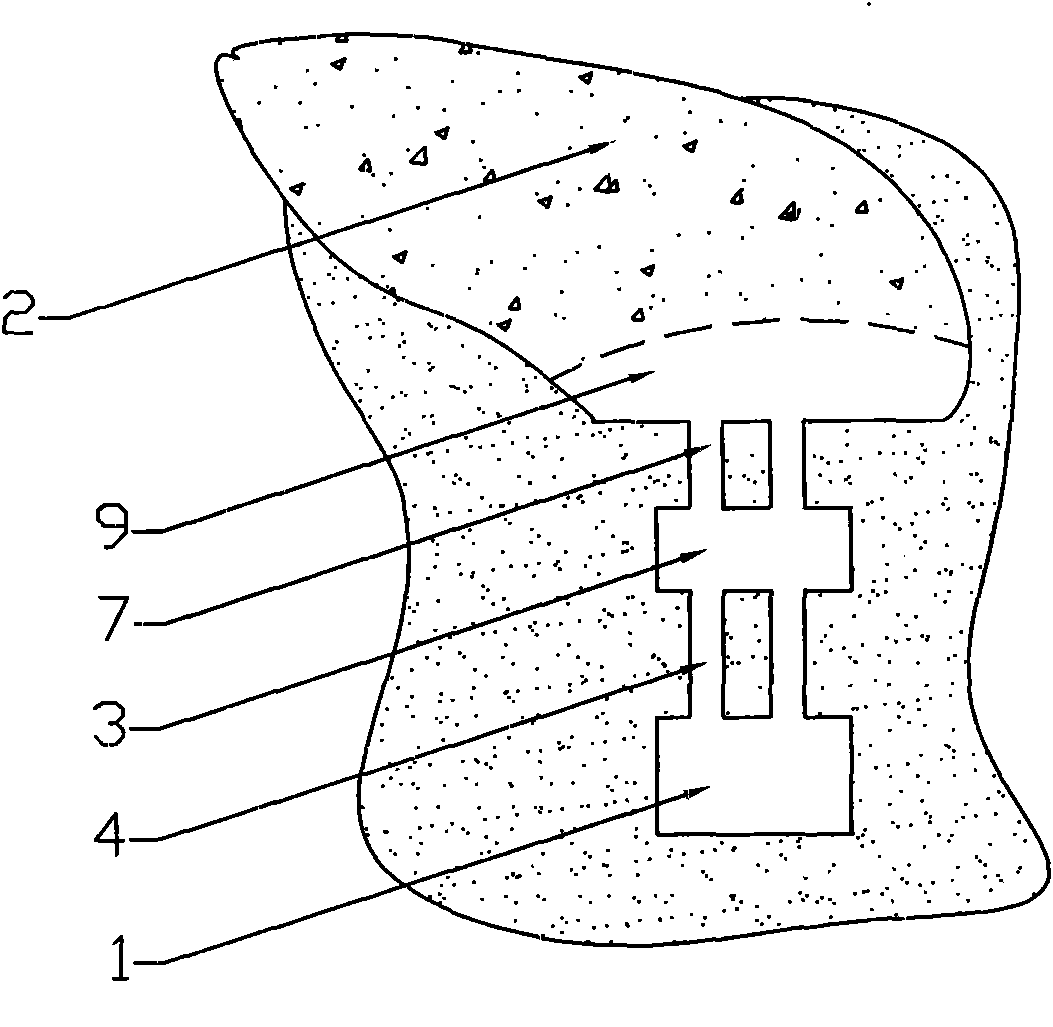

[0017] While presenting this method, see figure 1 with figure 2 , among which, 1-transportation alley; 2-coal seam; 3-monitoring lane; 4-down coal eye I; 5-sidewalk I; cavity. The mining steps of this self-falling and self-exiting coal mining method are:

[0018] (1) Excavation of transportation lane 1: about 10 to 15 meters away from the coal seam floor, excavate a horizontal transportation lane 1 along the direction of coal seam 2. The transportation lane 1 is used for coal transportation, ventilation and pedestrians; It falls into the transportation lane and is transported out by belts or vehicles; therefore, the size of the transportation lane is determined by the amount of coal dropped and the method of coal output (that is, how the coal is transported out). Usually, the width and height of the cross-section of the transportation lane vary. Less than 10~15×3~5 meters;

[0019] (2) Excavation monitoring lane 3: Excavate a monitoring lane 3 parallel to the transportati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com