Double-division auxiliary static-pressure bearing and turning worktable of machine tool

A technology of rotary table and hydrostatic support, used in manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of large wear of tapered sliding bearings, affecting the machining accuracy of gears, and reducing the machining accuracy of the whole machine. The effect of stable operation, simple and reasonable structure, and easy processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

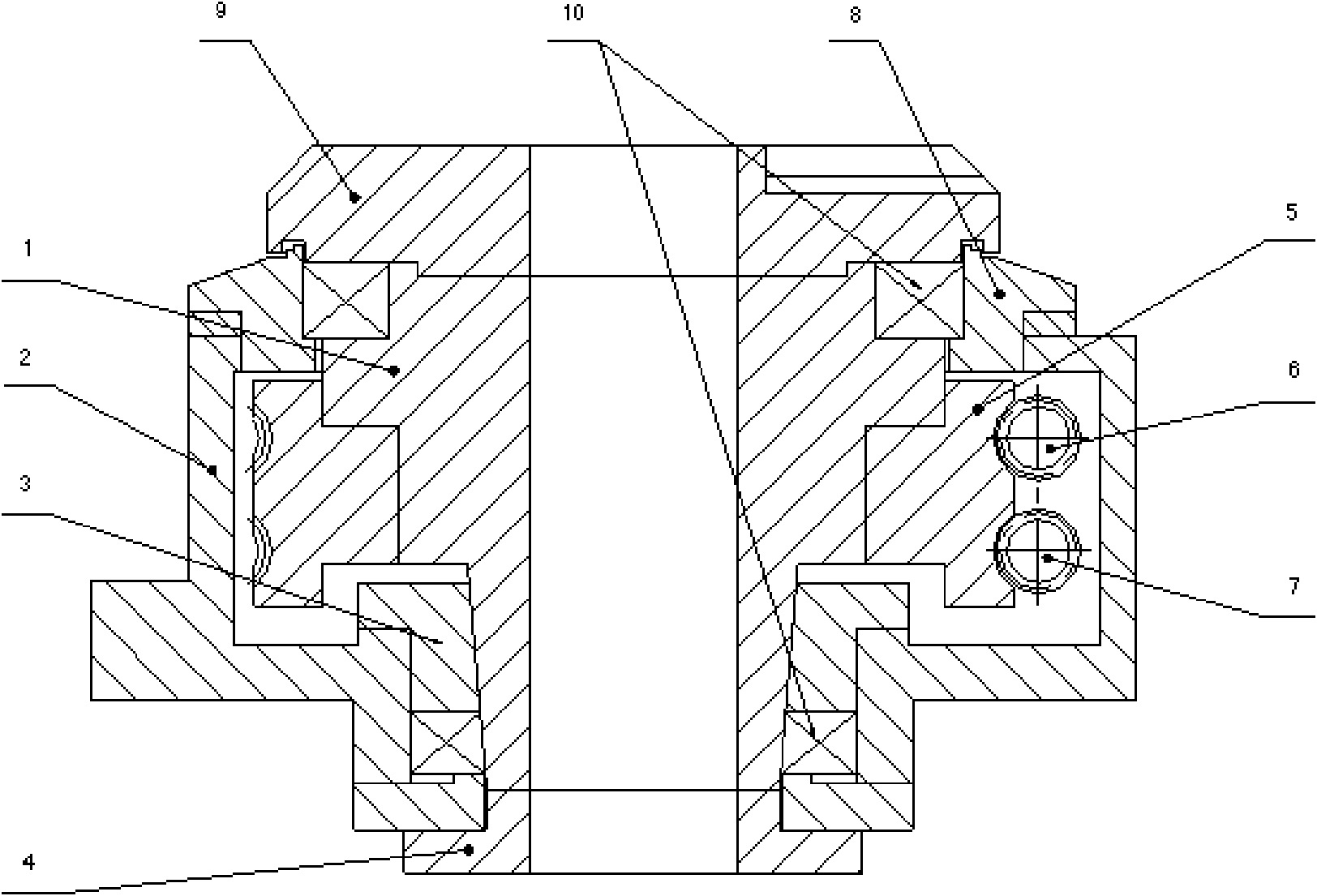

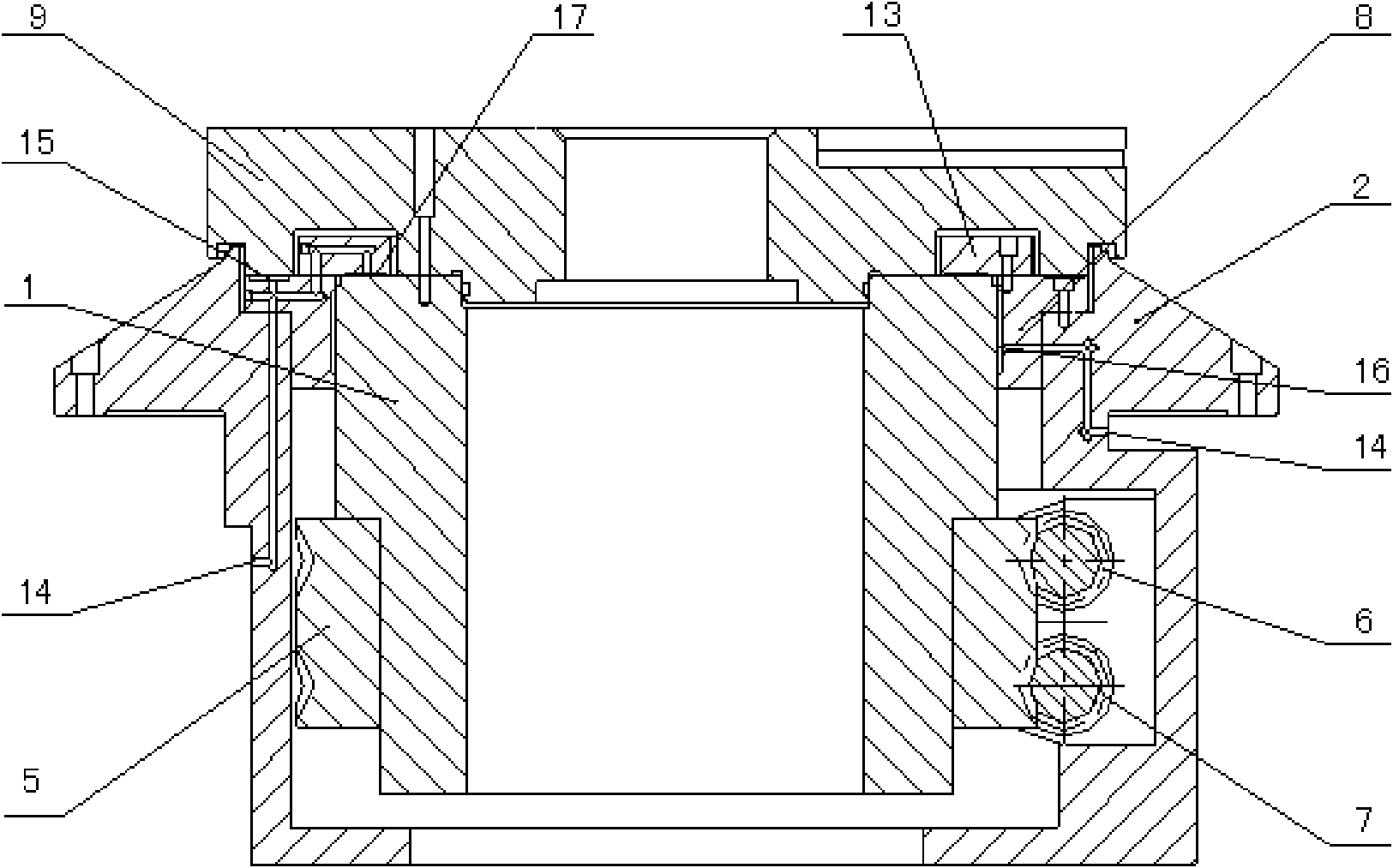

[0010] See attached figure 2 , the present invention --- a double indexing auxiliary hydrostatic support rotary table for machine tools, including a box body 2, a support ring 8, a mandrel 1, a driving worm 6, a damping worm 7, a worm wheel 5, and a table 9, the The support ring 8 is fixedly installed on the upper end surface of the box body 2, the worm gear 5 is sleeved on one end of the mandrel 1, and the other end of the mandrel 1 is inserted into the central through hole of the support ring 8 and passed through The screw is integrated with the table top 9, and a ring groove is provided between the table top 9 and the contact surface of the mandrel 1, and the ring pressure plate 13 fixedly connected with the support ring 8 is installed in the groove, so that The driving worm 6 and the damping worm 7 are supported in the box body 2 through bearings and engaged with the worm wheel 5, and 4-20 of the support ring 8 and the contact surface of the table 9 are evenly distributed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com