Sputtering target material and sputtering target obtained by using the sputtering target material

A sputtering target and sputtering target technology, applied in the field of sputtering targets, can solve the problems of reducing arcs, unable to fully suppress target cracks and cracks, etc., so as to reduce the generation of arcs and inhibit the generation of cracks or cracks. , the effect of preventing rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0060] Hereinafter, the present invention will be specifically described based on examples, but the present invention is not limited by these examples.

[0061] In addition, evaluation was performed according to the following evaluation items using the obtained sputtering target.

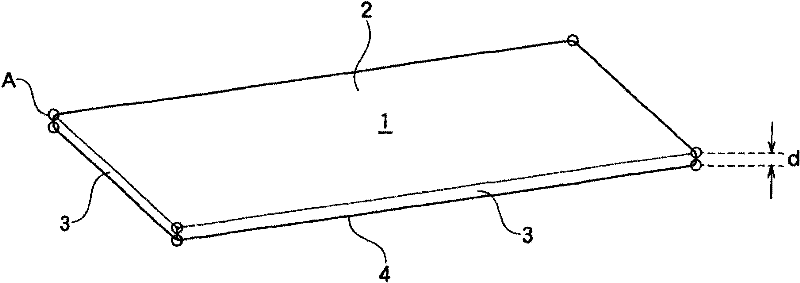

[0062] > The obtained sputtering target material was bonded (bonded) to a back plate made of oxygen-free copper using a bonding material (pure In). This sputtering target material was peeled off from a backing plate, and it bonded again using the adhesive material (pure In). After repeating this bonding ten times, it was checked whether or not a chip was formed on the sputtering target. ◯: Notch was not generated at all in the entire edge portion of the adhesive surface. Δ: 1 to 3 chippings occurred in all the edge portions of the bonding surface. ×: Four or more chippings occurred in all the edge portions of the adhesive surface.

[0063] > During the folding process, packaging process, or load...

Embodiment 2

[0070] [Example 2] An ITO sputtering target composed of the materials shown in Table 1 was manufactured, and C0.3 chamfering treatment was implemented on the four corners A of the sputtering surface 2, and on the bonding surface C0.5 chamfering is applied to the edges and corners.

[0071] Then, in the same manner as in Example 1, a sputtering target was produced, and various evaluations were performed. The obtained results are shown in Table 1.

Embodiment 10

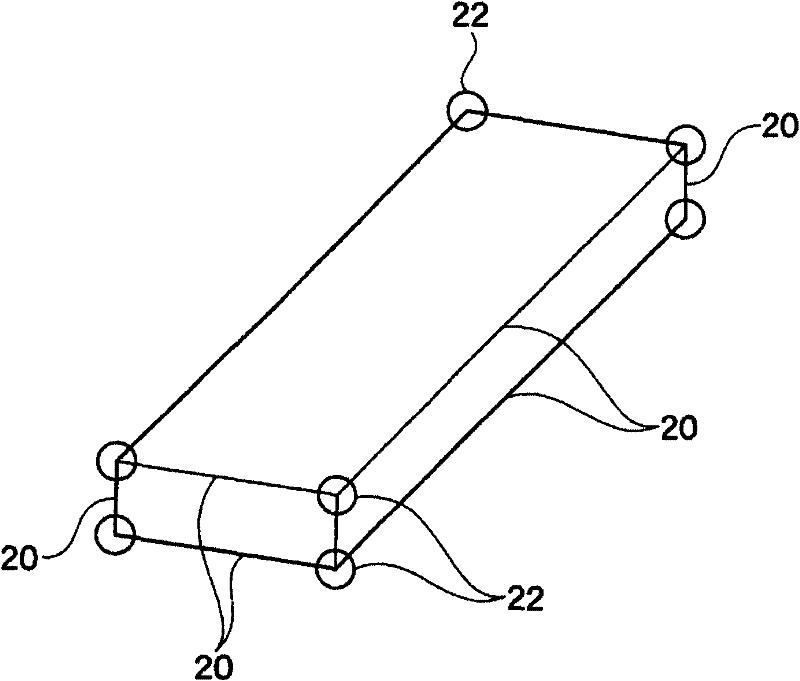

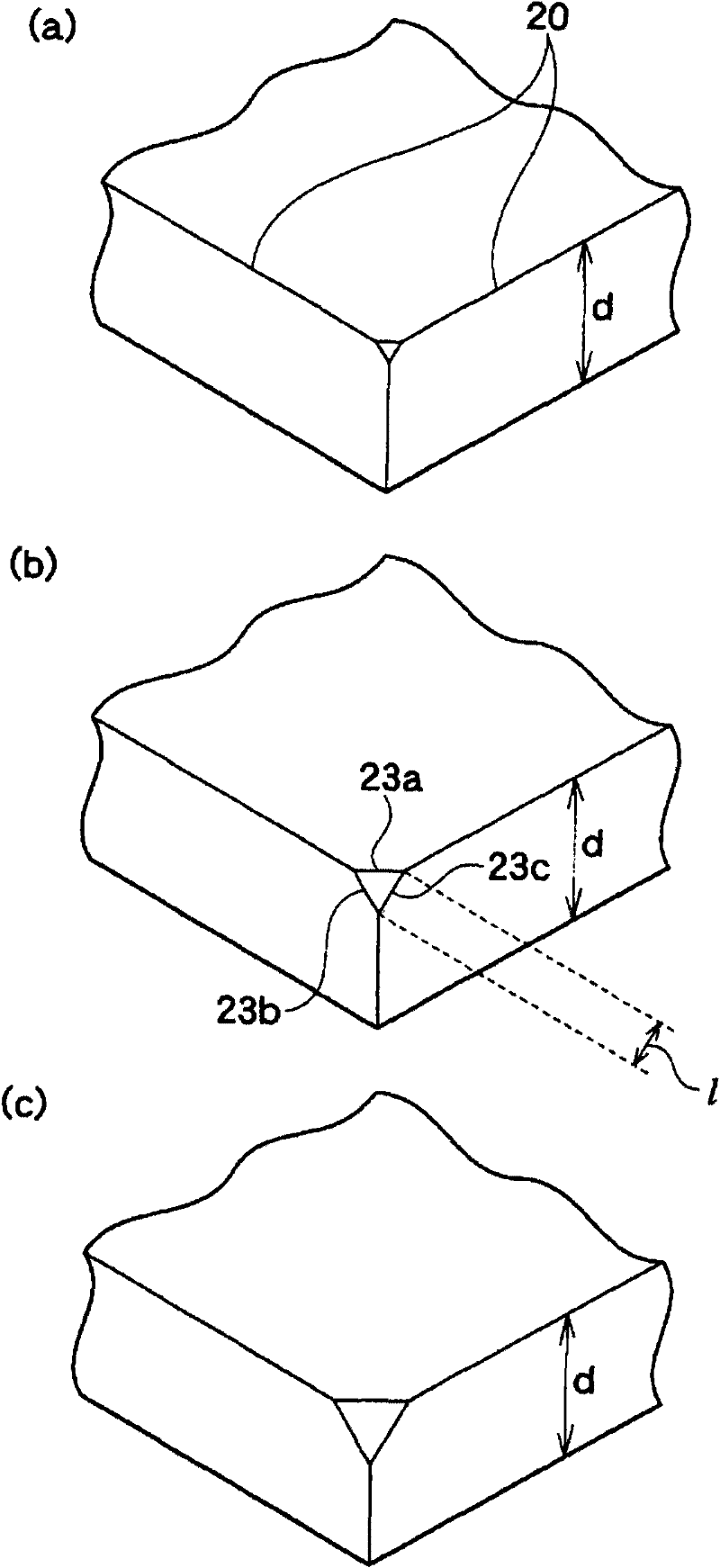

[0076] [embodiment 10] two wide 150mm * long 635mm * thick 10mm approximate plate-shaped ITO sputtering targets (SnO 2 =10% by weight, the relative density is 99.7%), R1 chamfering treatment was performed on the edge parts 45a-45c, and C3 chamfering treatment was performed on the edge part and corner part located on the bonding surface.

[0077] Then, these two sputtering targets were bonded to the back plate using the above-mentioned adhesive material, thereby producing a multi-segmented sputtering target in which the two sputtering targets were arranged side by side. The two sputtering targets were arranged such that their respective long sides were aligned in parallel with an interval of 0.3 mm. With respect to the sputtering surface, the chamfering process of R1 was given to the corner part B, and the chamfering process was also given to the corner part A located in the divided part where two sputtering targets oppose each other. Using the obtained multi-split sputtering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com