Optimization method for distance between headstock bearings of large ship used crankshaft lathe

A crankshaft lathe and bearing spacing technology, applied in metal processing equipment, etc., can solve the problems of late start, short time, time-consuming and laborious, etc., and achieve the effect of shortening the optimization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The simulation analysis method of the present invention will be further described below in conjunction with the accompanying drawings.

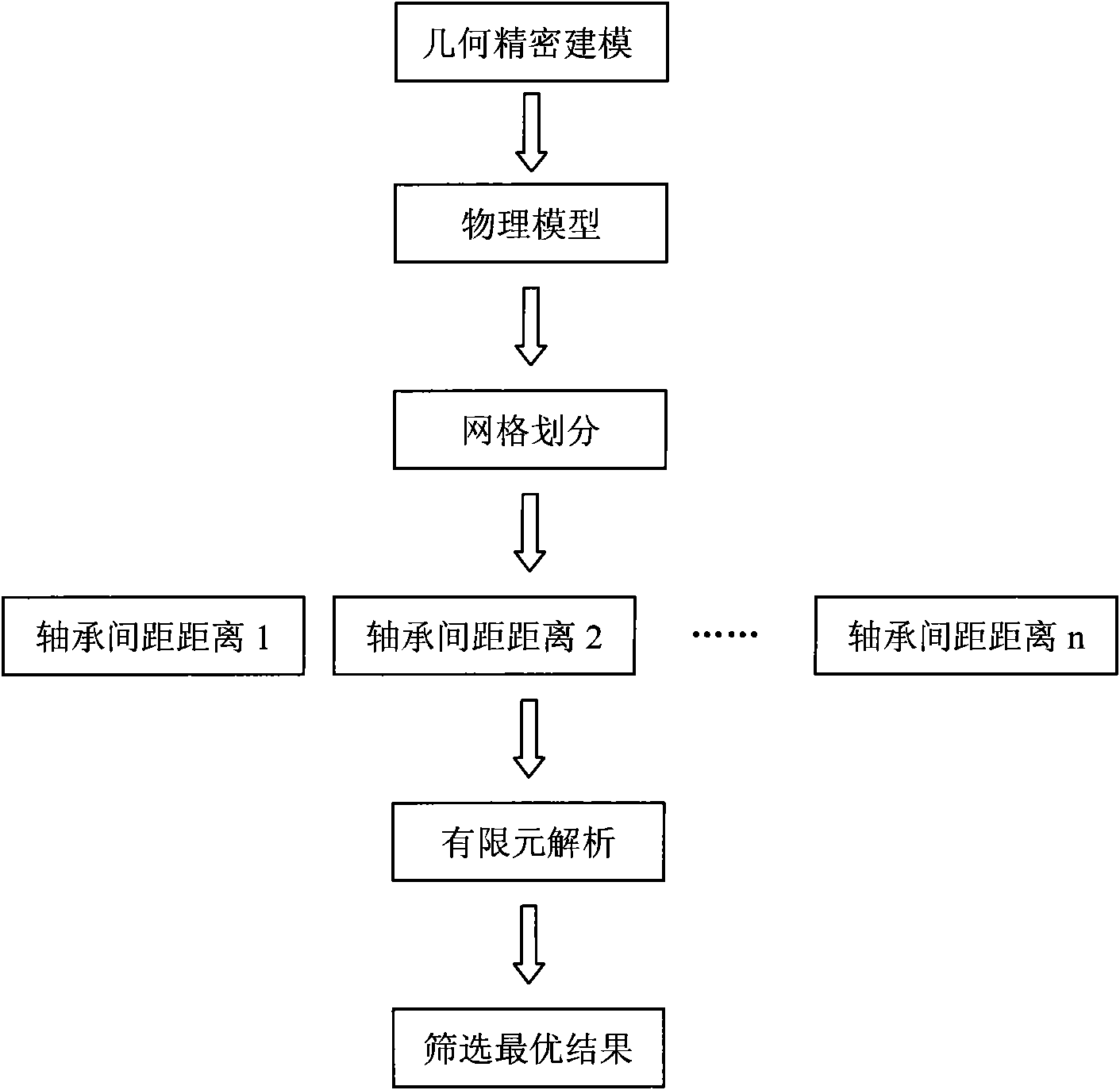

[0023] Taking static analysis as an example, the specific steps are as follows figure 1 Shown:

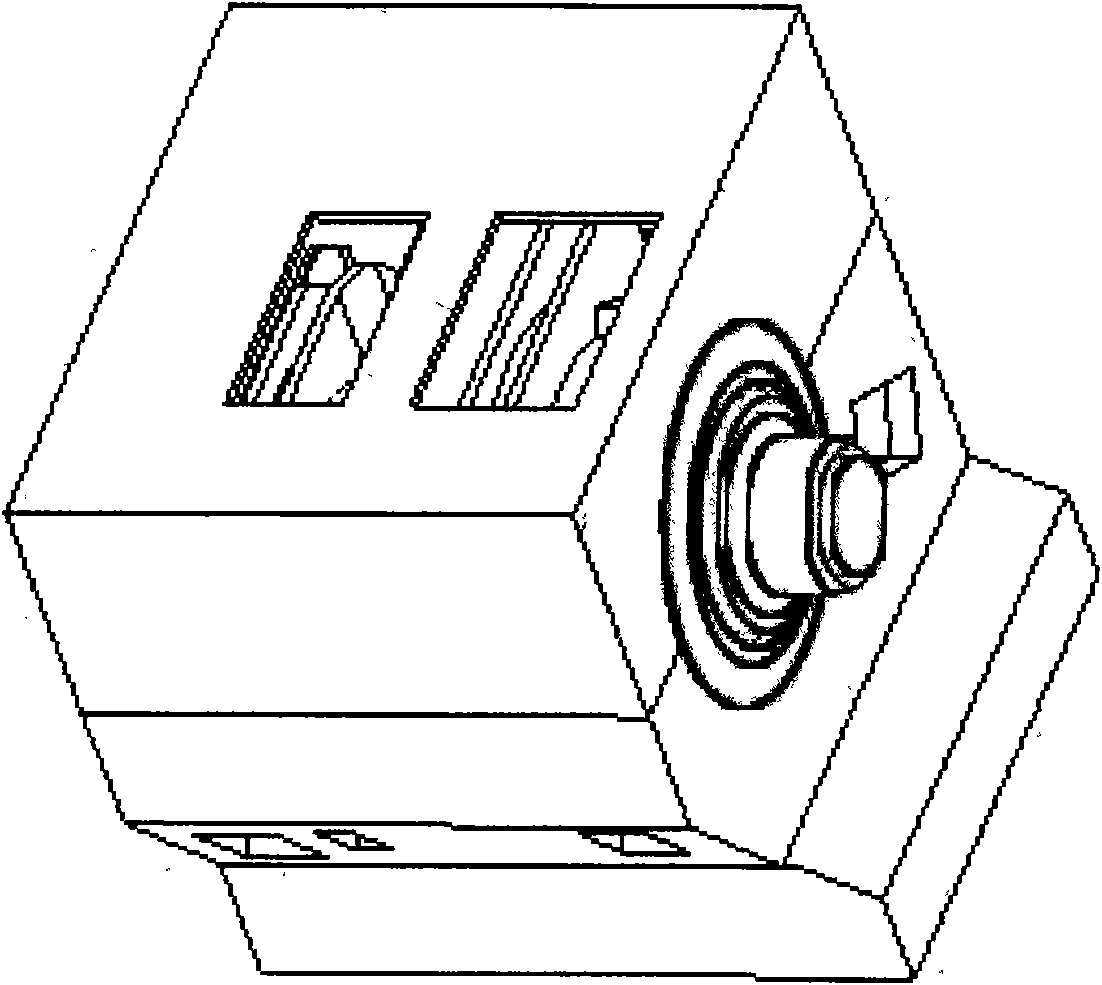

[0024] 1. Use PRO / ENGINEER for precise 3D geometric modeling

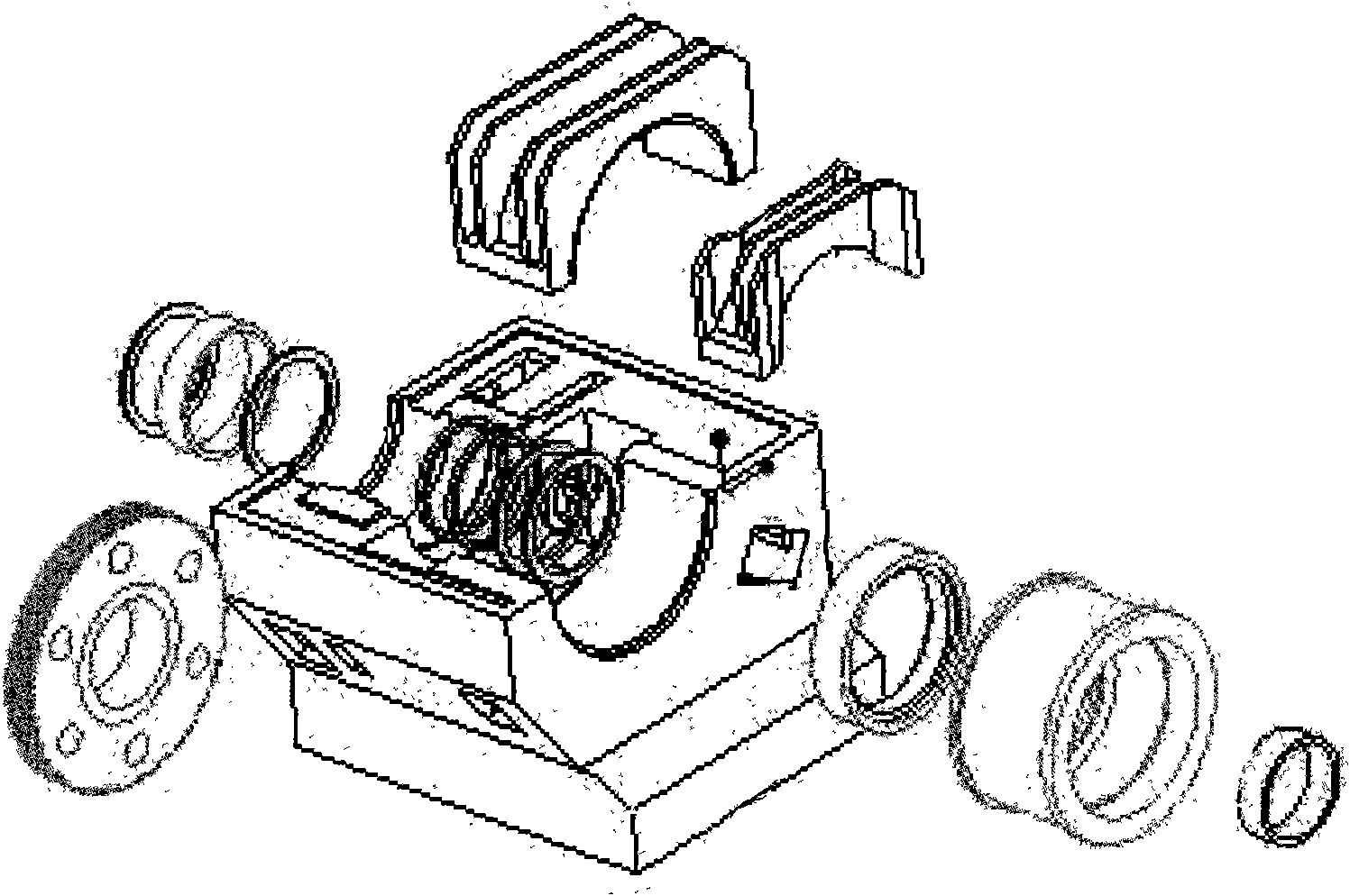

[0025] Use PRO / ENGINEER for precise modeling and assemble the model, such as figure 2 shown. image 3 is an exploded representation of the parts of the assembly drawing, showing that the model accurately simulates the actual physical model.

[0026] 2. Enter the PRO / ENGINEER sub-module PRO / MECHANICA, and impose physical constraints and various loads.

[0027] Set the physical characteristics of the model, various loads, boundary conditions and contact areas.

[0028] 3. Set the stiffness of the bearing

[0029] In various crankshaft lathes, there are various bearings, and the rigidity performance of each bearing is also different. Therefore, it should be set differently ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com