Mixed refrigerant re-circulated liquefaction process for precooling coalbed methane (CBM) by residual pressure of pressure swing adsorption (PSA)

A technology of mixed refrigerants and pressure swing adsorption, which is applied in refrigeration and liquefaction, liquefaction, chemical industry, etc., can solve the problems of reduction and insignificant energy saving effect of coalbed methane, and achieve the effect of reducing the power consumption of liquefaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

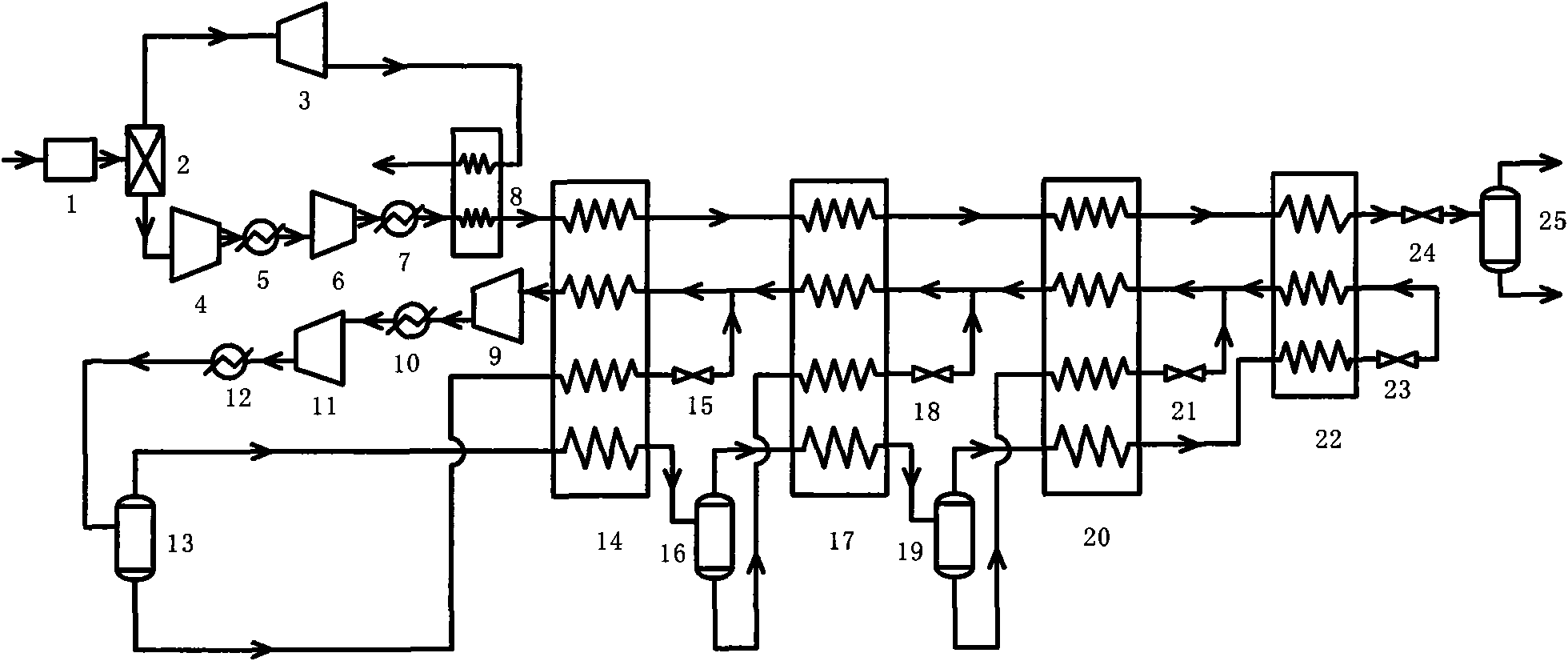

[0020] Implementation Option 1: If figure 1 As shown, the coalbed methane mixed refrigerant circulation liquefaction process using pressure swing adsorption residual pressure precooling in the four-stage cooling process when the temperature after precooling of coalbed methane is greater than 0 ° C includes the following steps:

[0021] 1. Water, acid gas and heavy hydrocarbon impurities are removed in the pre-purification system 1 of the pressurized normal-temperature coalbed methane raw material gas;

[0022] 2. The pre-purified coalbed methane is concentrated in the adsorber 2 through the pressure swing adsorption process, and the concentrated coalbed methane with residual pressure nitrogen and normal pressure is separated;

[0023] 3. The concentrated coalbed methane is compressed to a medium pressure of 0.6-0.8 MPa by the primary methane compressor 4 and compressed by the secondary methane compressor 6 to be greater than or equal to 4.5 MPa, and is respectively cooled in t...

Embodiment approach 2

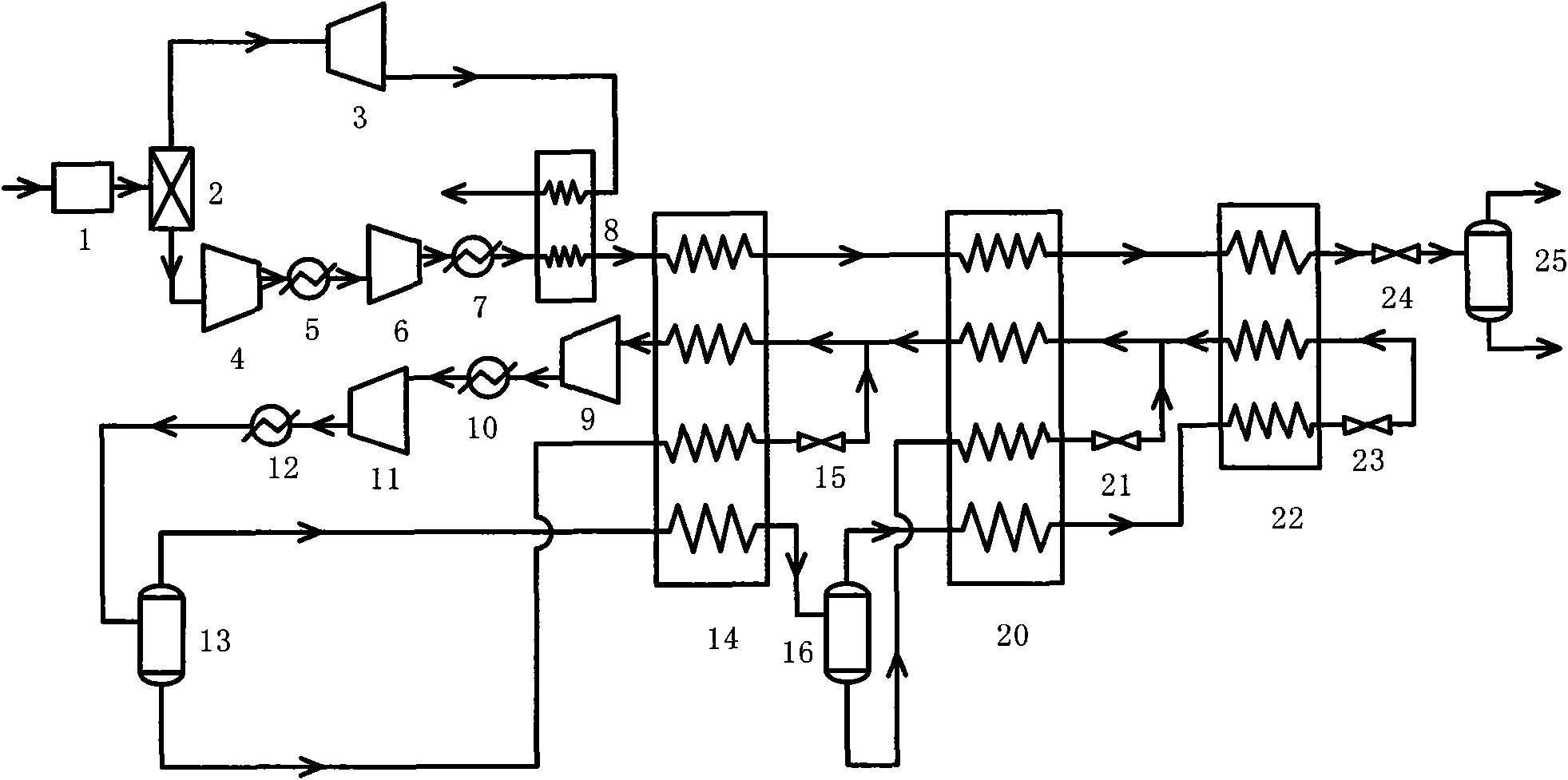

[0027] Implementation Option 2: If figure 2 As shown, the coalbed methane mixed refrigerant circulation liquefaction process using pressure swing adsorption residual pressure precooling in the three-stage cooling process when the temperature after precooling of coalbed methane is -60 ~ 0 ° C includes the following steps:

[0028] Step 1, step 2, step 3 and step 4 are respectively the same as step 1, step 2, step 3 and step 4 in embodiment 1;

[0029]5. The pre-cooled concentrated coalbed methane is cooled to -60°C by the second heat exchanger 14, cooled to -130°C by the fourth heat exchanger 20 and cooled to -155°C by the fifth heat exchanger 22 to become a low-temperature coal seam The cooling capacity in these three heat exchangers is provided by the mixed refrigerant cycle. The above-mentioned mixed refrigerant cycle is as follows: a certain amount of mixed refrigerant at normal temperature and pressure is compressed to a medium pressure of 0.8-1.0 MPa by the primary refr...

Embodiment approach 3

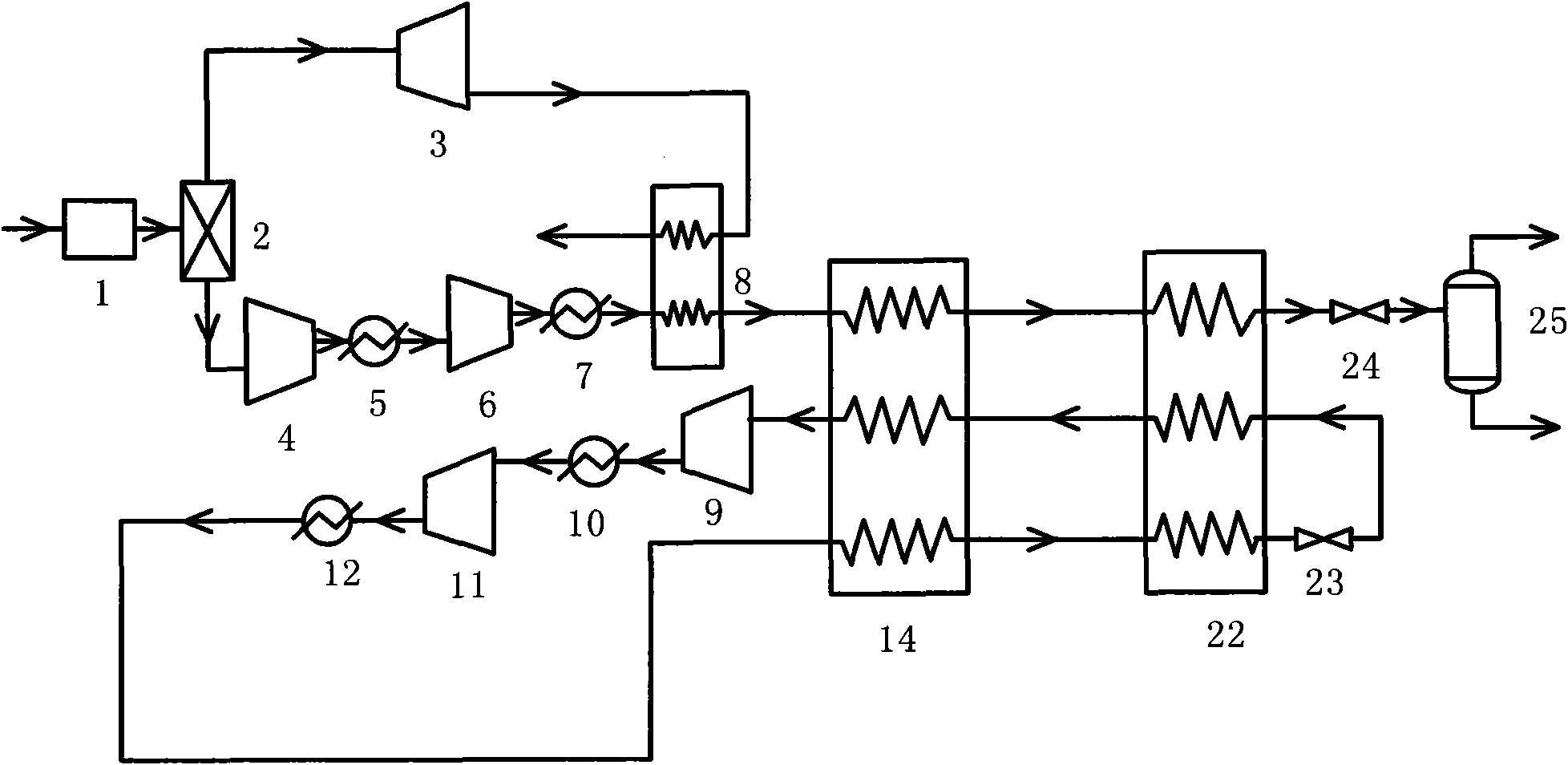

[0031] Implementation Option 3: If image 3 As shown, the coalbed methane mixed refrigerant cycle liquefaction process using pressure swing adsorption residual pressure precooling in the secondary cooling process when the temperature of coalbed methane precooling is lower than -60 ° C includes the following steps:

[0032] Step 1, step 2, step 3 and step 4 are respectively the same as step 1, step 2, step 3 and step 4 in embodiment 1;

[0033] 5. The pre-cooled concentrated coalbed methane is cooled to -130°C by the second heat exchanger 14 and cooled to -155°C by the fifth heat exchanger 22 to become low-temperature coalbed methane. The cooling capacity of these two heat exchangers Provided by the mixed refrigerant cycle; the above mixed refrigerant cycle is: a certain amount of mixed refrigerant at normal temperature and pressure is compressed to a medium pressure of 0.8-1.0 MPa by the primary refrigerant compressor 9 and compressed by the secondary refrigerant compressor 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com