Corrugating machine capable of quickly changing roll

A corrugating machine, fast technology, applied in the direction of machining/deformation, etc., can solve the problems of time-consuming and labor-intensive, long time for roll change, etc., to achieve the effect of wide adjustment range, stable pressure, and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

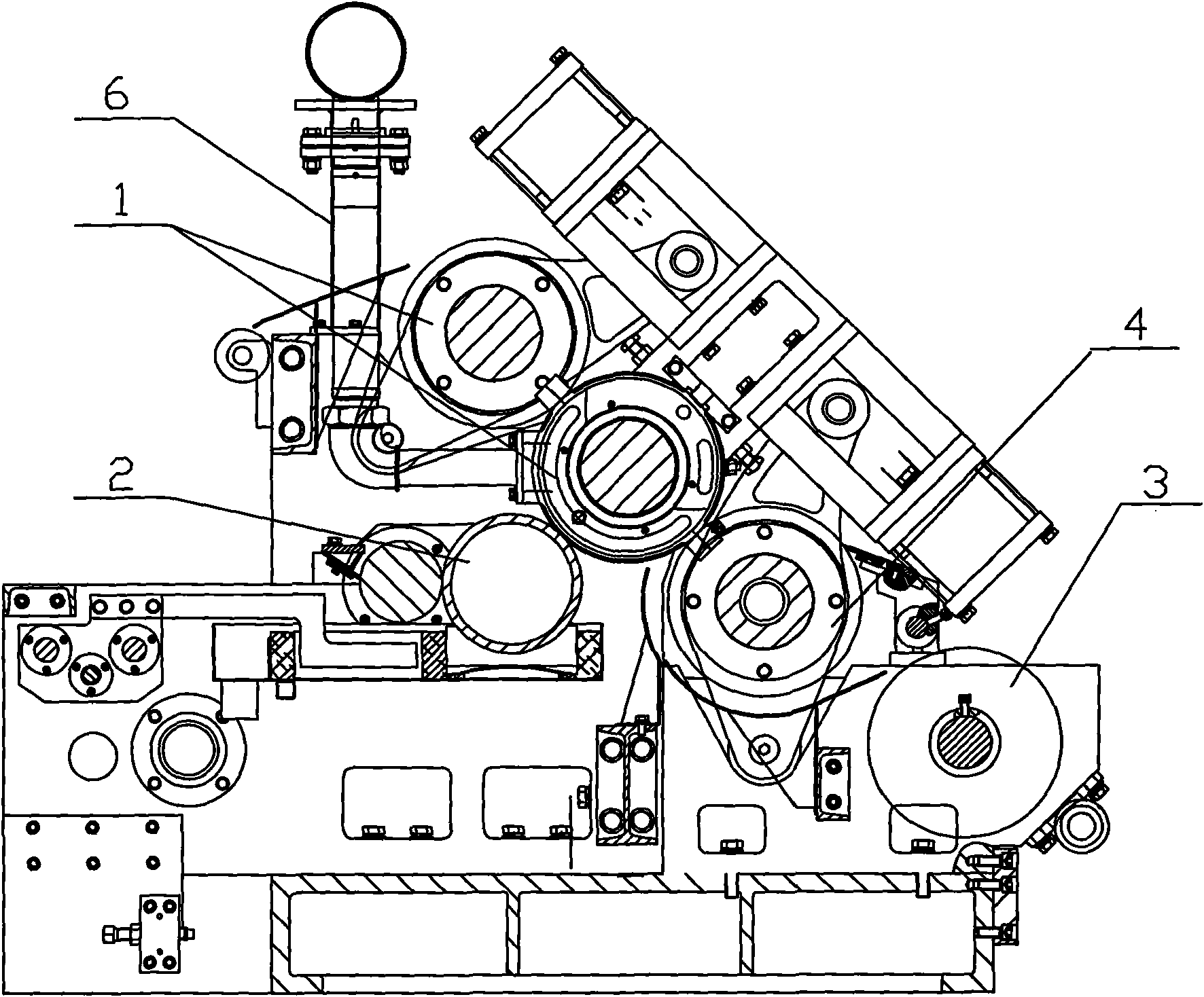

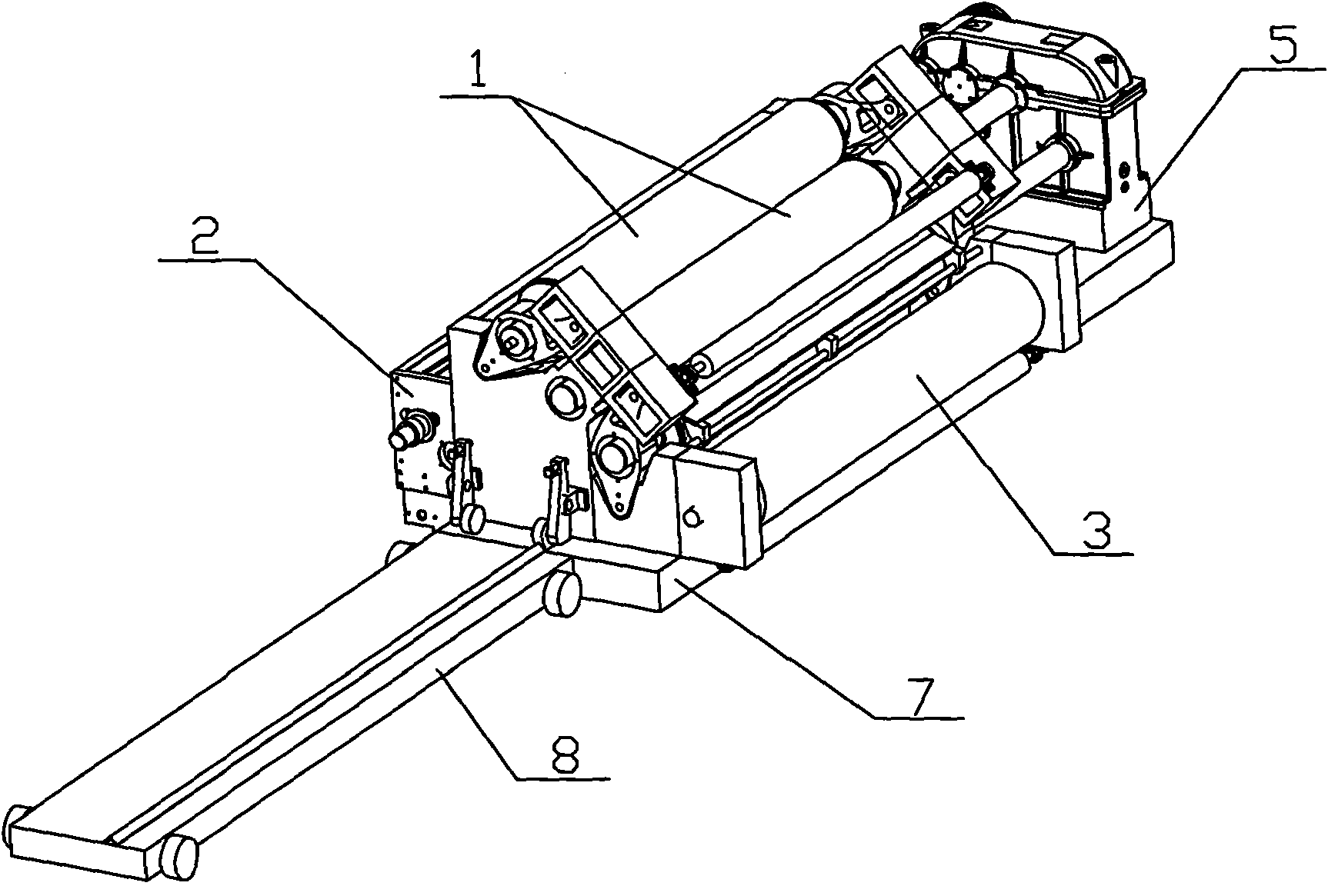

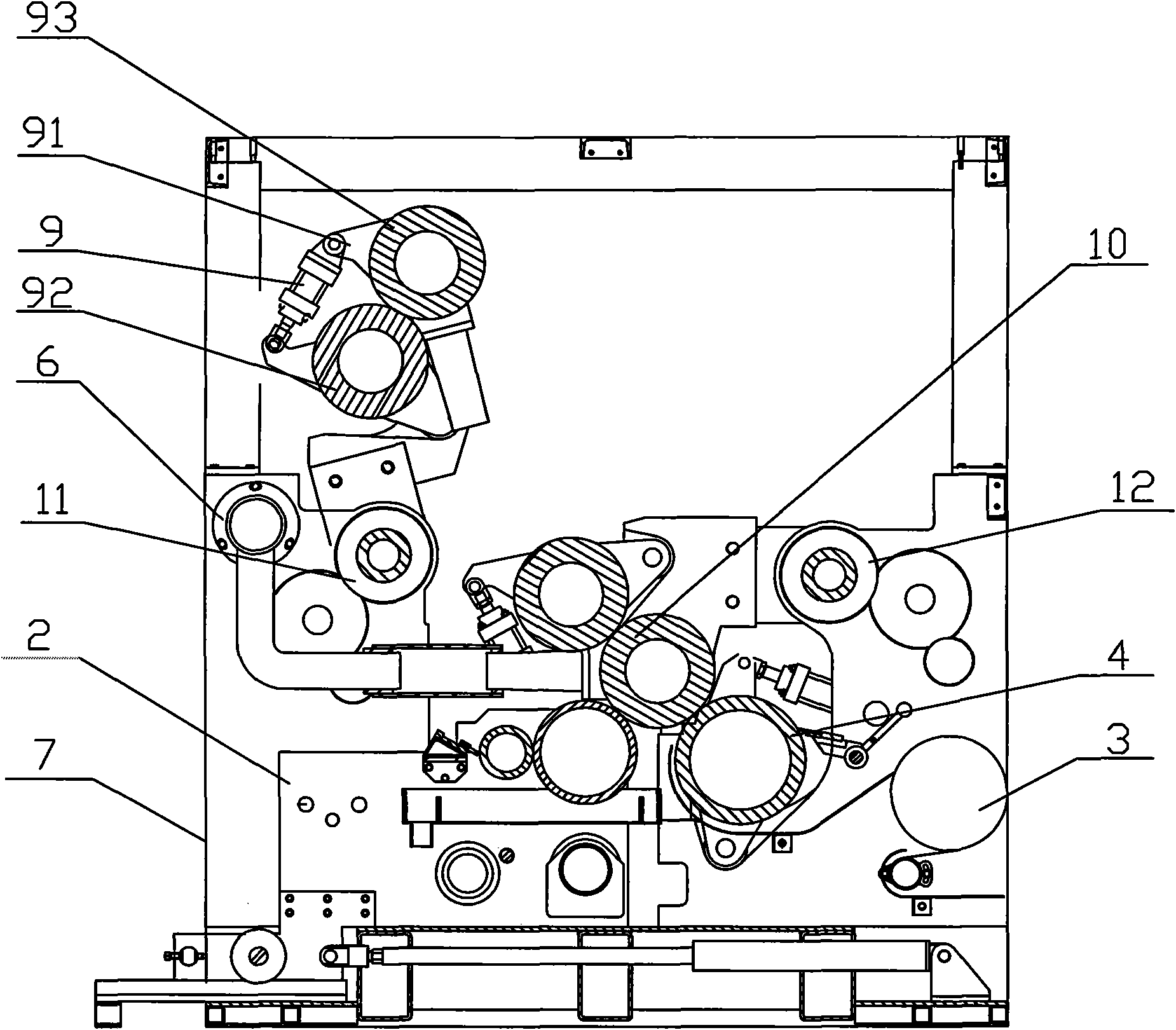

[0025] like image 3 , 4 , 5. The corrugating machine capable of quickly changing rolls according to the present invention includes a frame 7, a sizing mechanism 2 fixed on the frame 7, a preheating mechanism 3, and left and right toothed roller mechanisms that can suppress corrugated paper of different corrugated shapes 9, 10, wherein, the left toothed roller mechanism includes a toothed roller seat 91, and the upper corrugating roller 92 and the lower corrugating roller 93 installed on the toothed roller seat 91, the right toothed roller mechanism includes a toothed roller seat 101, and is installed on the toothed roller The upper corrugating roller 102 and the lower corrugating roller 103 on the seat 101, when the lower corrugating rollers 93, 103 are in the working position, the corresponding pressing roller mechanism 4, the left and right toothed roller mechanisms 9, 10, and the pressing roller mechanism 4 are also arranged below it. It is connected with a hydraulic syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com