Full-automatic rewinding machine capable of continuously producing paper scroll with/without core without halt

A fully automatic, rewinder technology, used in strip winding, transportation and packaging, thin material handling, etc., can solve the problems of long downtime, inconvenient paper threading, and easy coreless rolls to improve The effect of production efficiency, paper threading convenience, and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

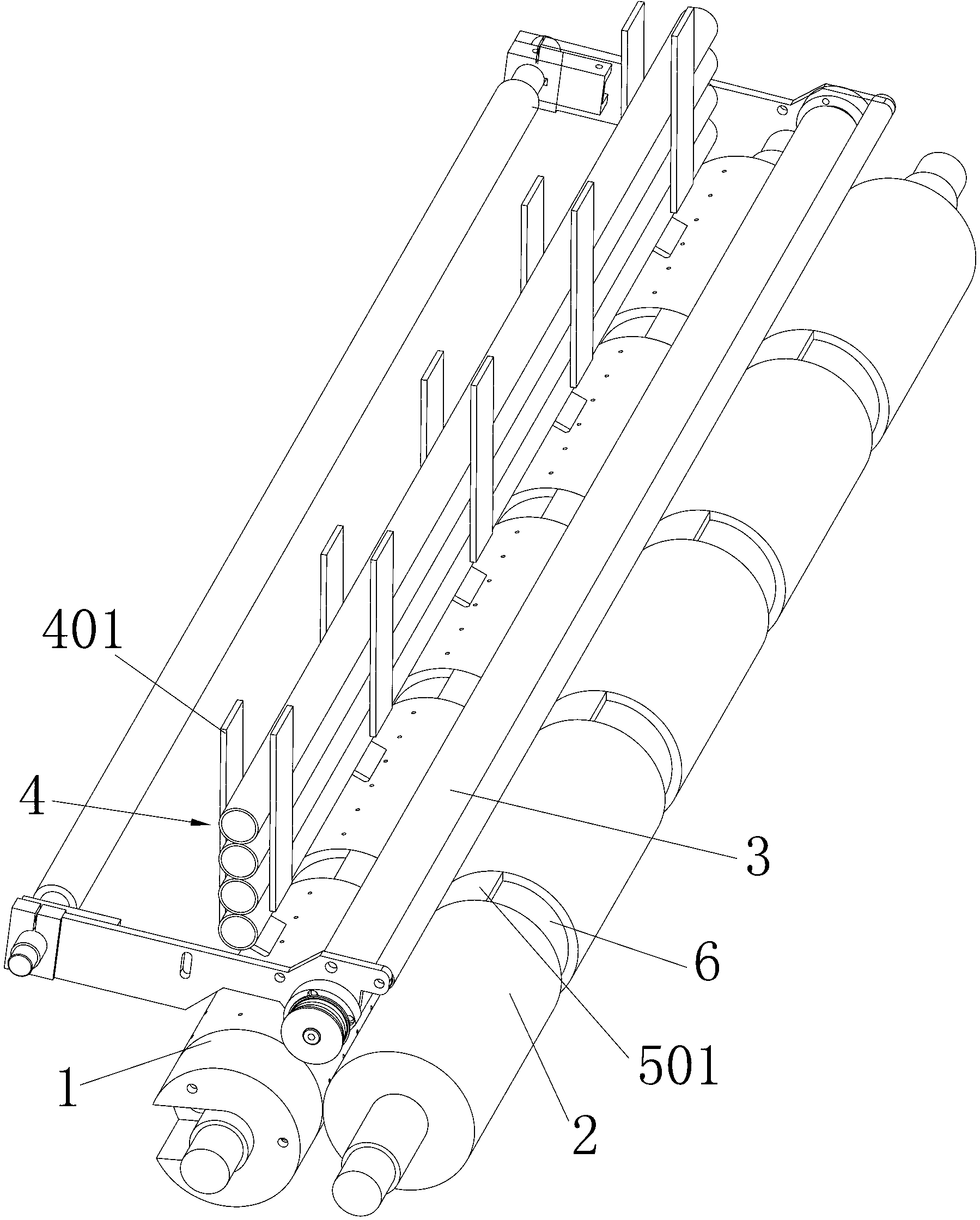

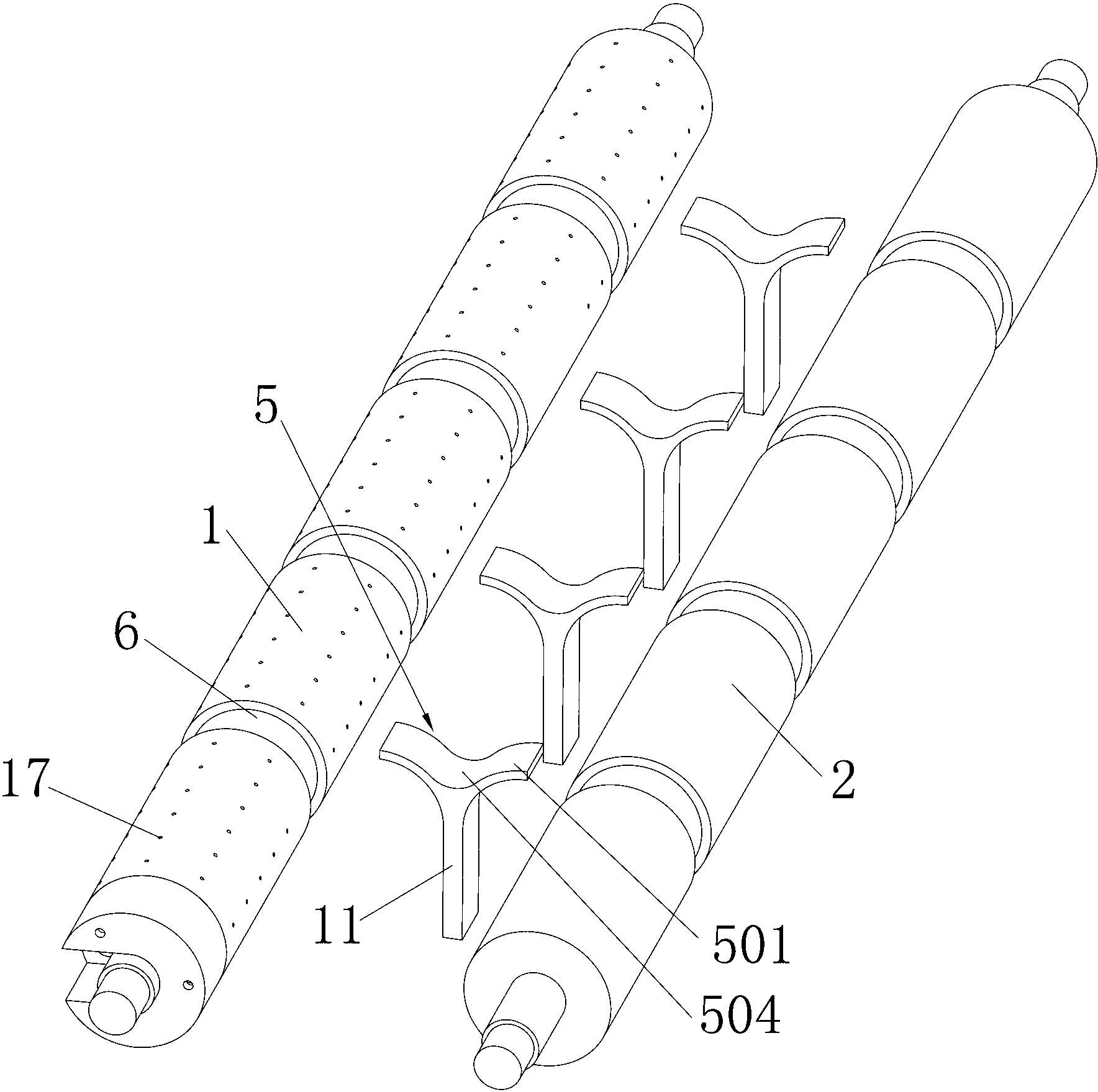

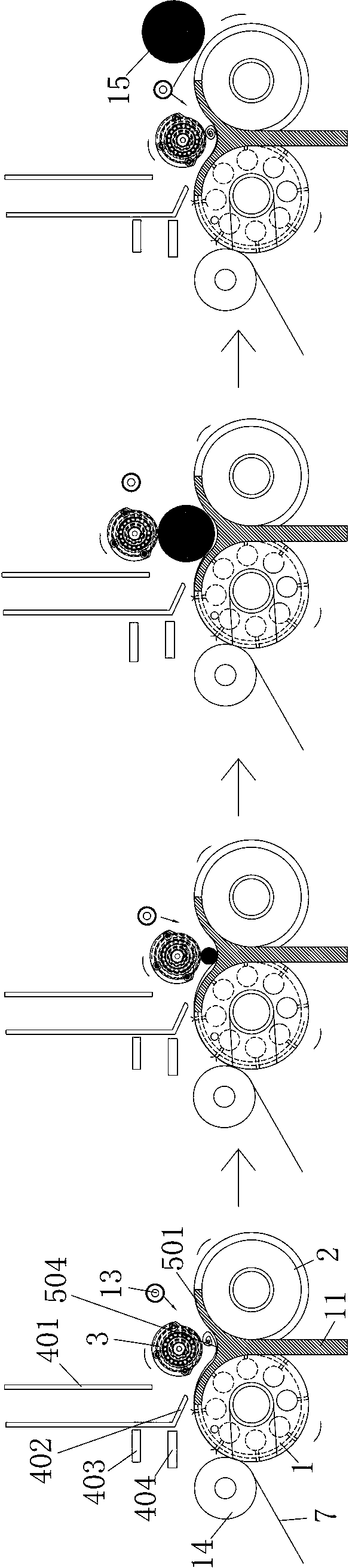

[0031] Embodiment 1: see attached figure 1 to attach Figure 4As shown, the fully automatic rewinding machine described in this embodiment, which can continuously produce cored and coreless paper rolls without stopping the machine, includes a first winding roller 1, a second winding roller 2, and a winding pressure roller parallel to each other. 3. The paper feeding press roller 14 and the paper tube supply mechanism 4, wherein the first winding roller 1 is correspondingly arranged between the paper feeding pressing roller 14 and the second winding roller 2, and is connected with the paper feeding pressing roller respectively. 14 and the second winding roller 2 are arranged adjacent to each other and there is a gap, and the roller surface of at least one winding roller is distributed with a plurality of suction holes 17 capable of vacuum adsorption along its circumferential direction, and in this embodiment, the first The roll surface of the winding roller 1 is distributed al...

Embodiment 2

[0032] Embodiment 2: see attached Figure 5 to attach Figure 7 As shown, the difference from Example 1 is that the two-way lap roll-assisting sheathing plate 5 of this embodiment is provided with an air blowing hole 502 that can blow air to the crotch. There is a suction hole 503 at the bottom of the mouth that can be vacuumed. When coreless paper roll production is required, the base paper head that enters the rewinding area of the paper roll will be sucked by the suction hole 503 first, so that it can come accurately. Two-way lapping at the mouth 504 of the roll-assisting cover plate 5, and then blowing air on the base paper head through the air blowing hole 502, so that it can be rolled up quickly; the air blowing hole 502 and the air suction hole 503 can effectively ensure that the base paper 7 Accurate, fast and reliable rolling at Yakou 504.

Embodiment 3

[0033] Embodiment 3: see attached Figure 8 to attach Figure 10 As shown, the difference from Example 1 is that the bottom of the crotch of the two-way lap roll-assisting cover plate 5 described in this embodiment is provided with a rotating wheel 10 that can hold the paper and roll it up. Through this rotating wheel 10, it can effectively ensure that the base paper 7 Fast, accurate and reliable roll-up at the mouth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com