Automatic control bioreactor for breeding maggots and earthworms and culture method

A reactor and bioreactor technology, applied in animal husbandry and other directions, can solve the problems of complex separation process, inability to realize online control of device temperature control and humidity control, etc., to expand the scale of operation, realize waste recycling, and overcome difficult operation sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

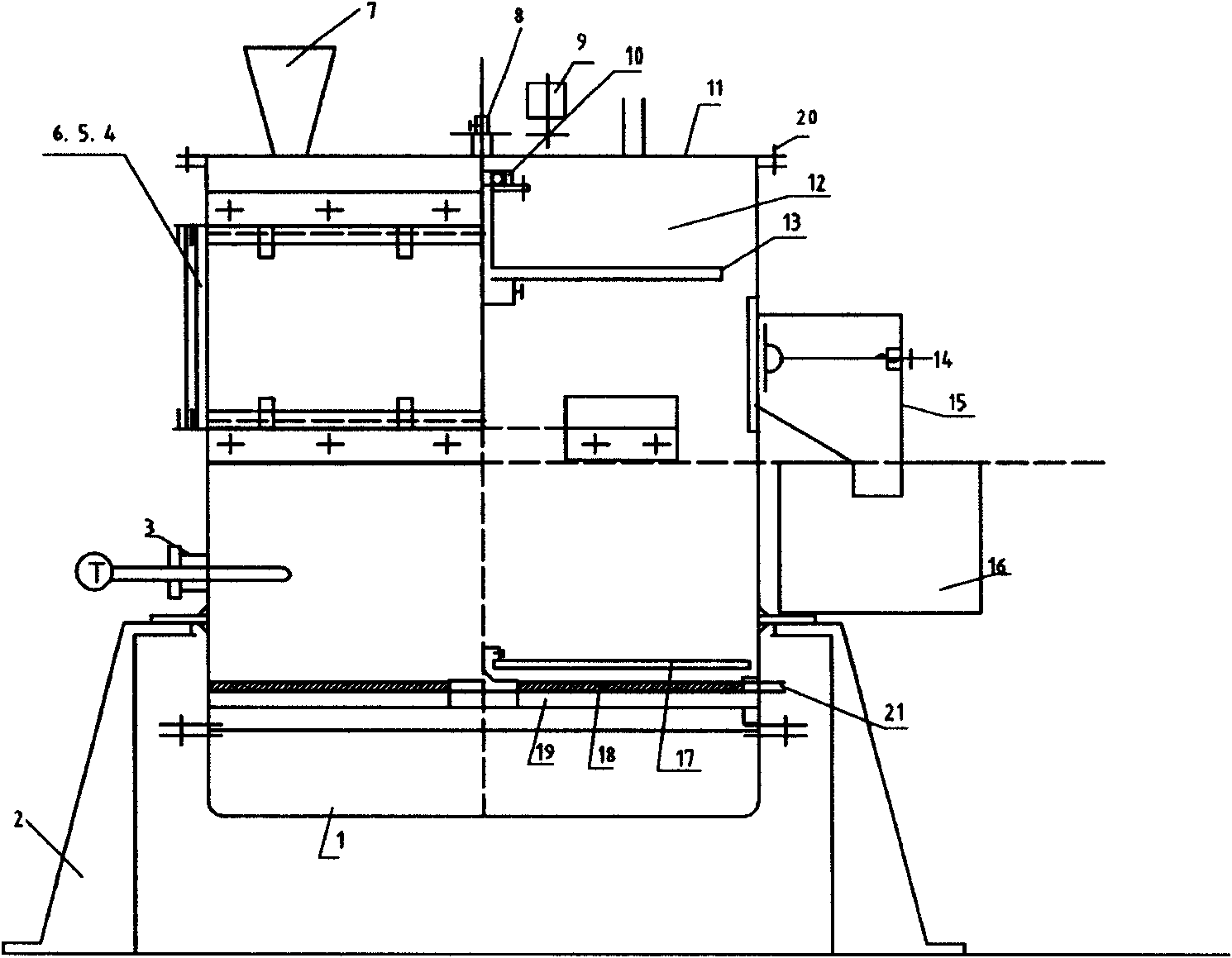

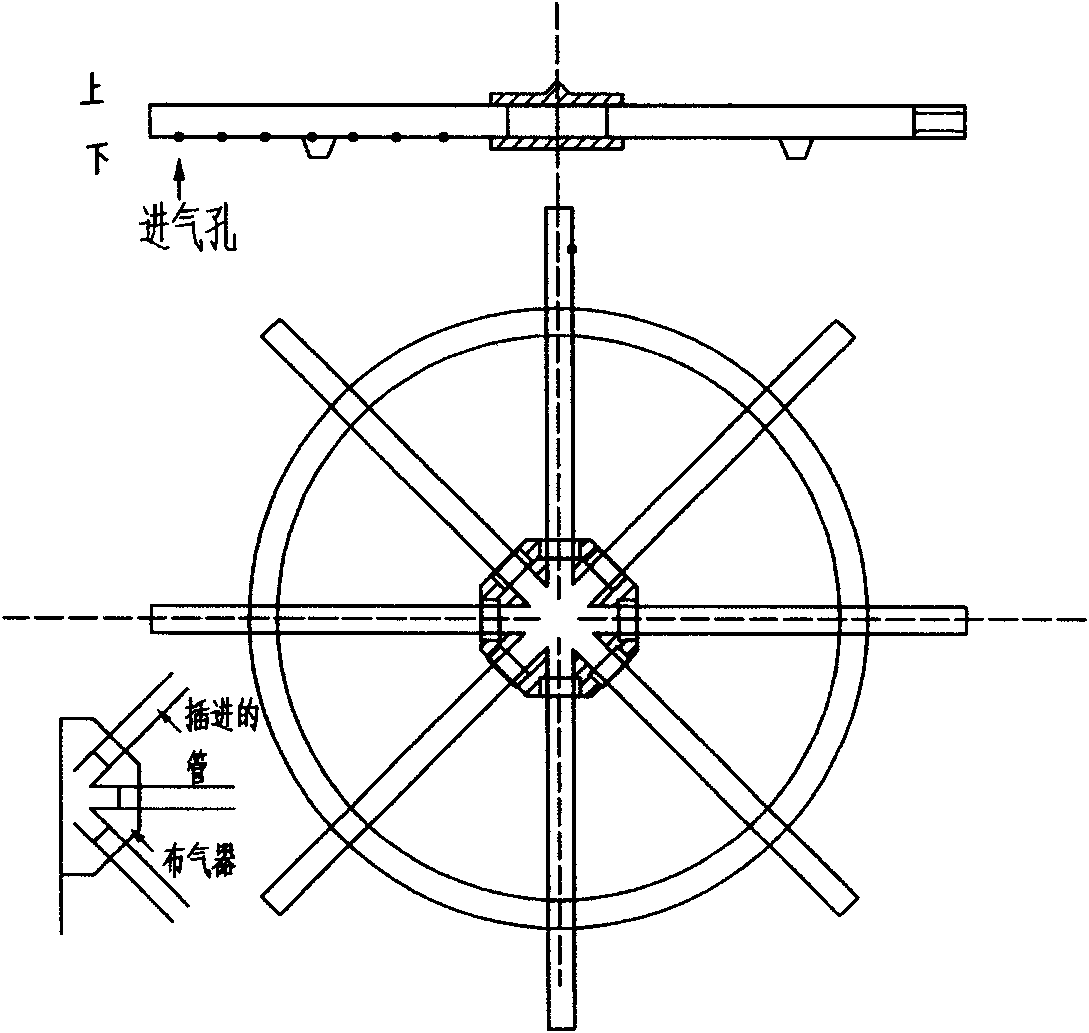

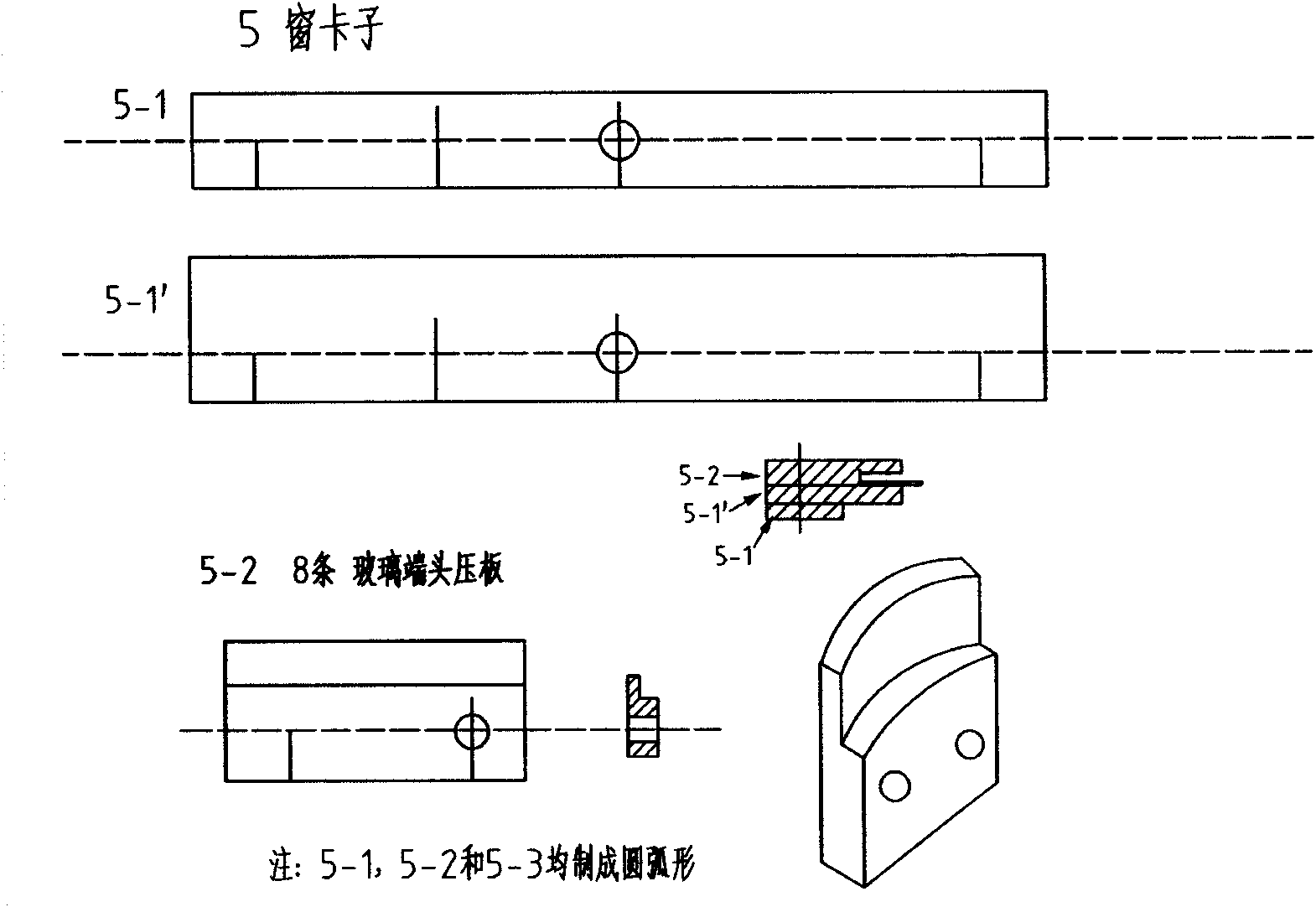

[0030] Add the steam-exploded straw material with a humidity of 75% into the reactor barrel 12 through the feeding port 7, spread the material evenly through the distributor 13 and mix evenly, and start the cold mold cultivation after closing the plexiglass window 4. The cold mold experiment requires that the temperature of the material layer be controlled at 35° C. and the humidity 75% to facilitate the cultivation of fly maggots. After the cultivation starts, the thermocouple and the hygrometer 3 display the temperature of 24° C. and the humidity of 75%, respectively. It is necessary to adjust the temperature of the external air inlet 21 through an external heat exchanger. First, 40°C hot air is introduced to heat the material layer, and the air inlet 19 is dispersed into the interior of the reactor to adjust the temperature. After heating for a period of time, the temperature reaches 35°C, and then the insulation static cultivation is started. When the material layer humidit...

Embodiment 2

[0032] Add the steam-exploded straw material with a humidity of 75% into the reactor barrel 12 through the feeding port 7, spread the material evenly through the distributor 13 and mix evenly, and start the cold mold cultivation after closing the plexiglass window 4. The cold mold experiment requires that the temperature of the material layer be controlled at 25° C. and the humidity 75%. After the cultivation starts, the thermocouple and the hygrometer 3 display the temperature of 20° C. and the humidity of 75%, respectively. It is necessary to adjust the temperature of the external air inlet 21 through an external heat exchanger. Firstly, 30°C hot air is introduced to heat the material layer, which is dispersed into the reactor by the air inlet 19 to adjust the temperature and humidity. At 75%, the material bed is humidified by feeding humid air. By implementing the cold model experiment, the temperature and humidity control in the reactor can be quickly realized, and the ex...

Embodiment 3

[0034] Add the steam-exploded straw material with a humidity of 50% into the reactor barrel 12 through the feeding port 7, spread the material evenly through the distributor 13 and mix evenly, and start the cold mold cultivation after closing the plexiglass window 4. The cold mold experiment requires that the temperature of the material layer be controlled at 25° C. and the humidity 75%. After the cultivation starts, the thermocouple and the hygrometer 3 display the temperature of 21° C. and the humidity of 50%, respectively. It is necessary to adjust the temperature of the external air inlet 21 through an external heat exchanger. Firstly, 30°C hot and humidified air is introduced to heat and humidify the material layer, and the air inlet 19 is dispersed into the reactor to adjust the temperature and humidity. After heating and humidifying for a period of time, the humidity first reaches 75%, and then the air is adjusted to enter the drying process. Hot air, the temperature re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com