Hydraulic tensioning element for a traction mechanism drive

A driver and component technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem of insufficient piston accuracy, and achieve the effect of improving guiding accuracy and mechanical vibration damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

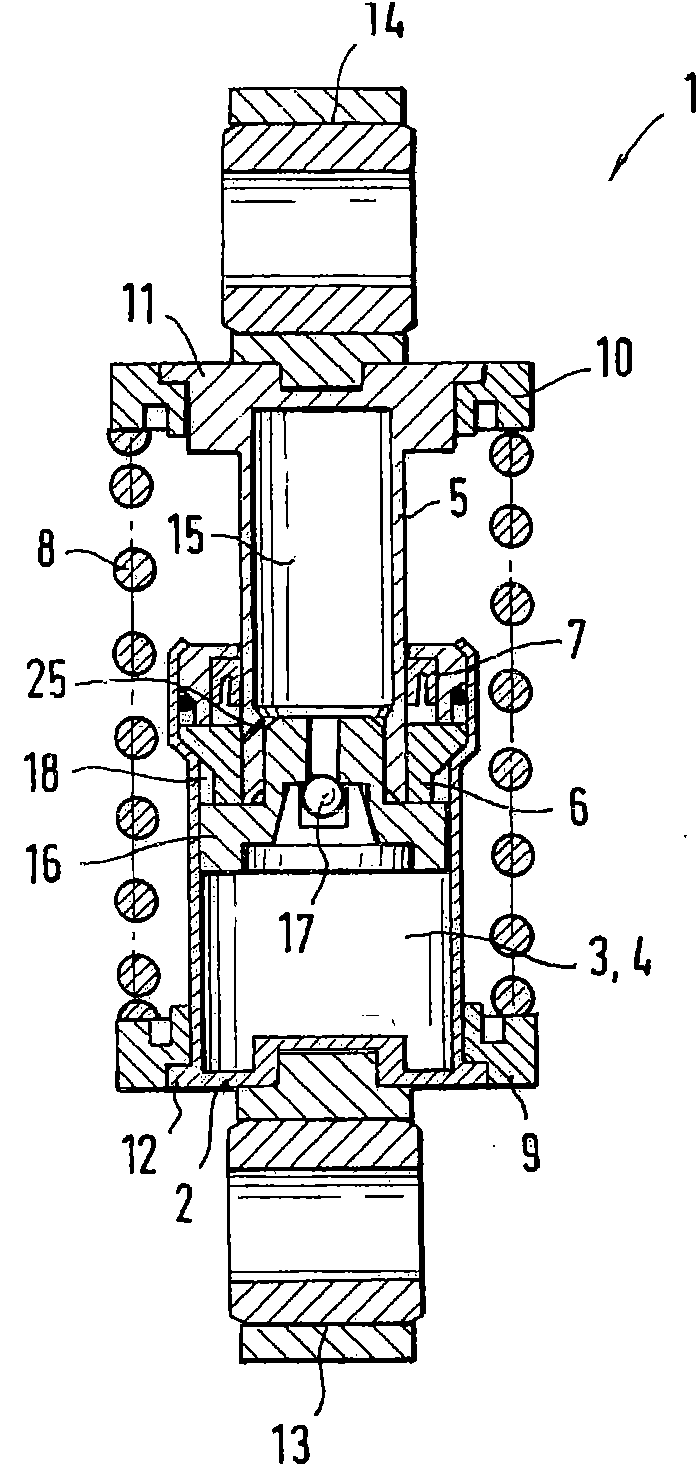

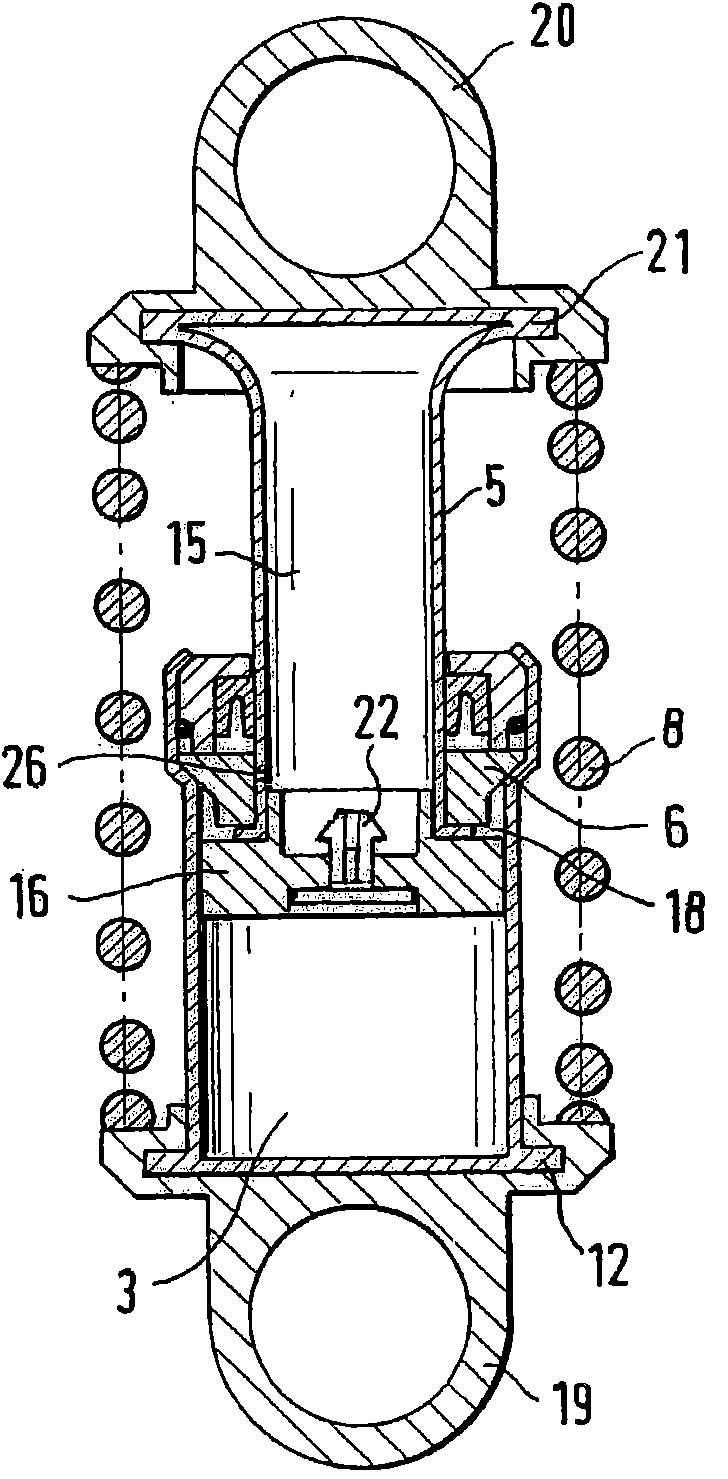

[0019] figure 1 A longitudinal section through a first exemplary embodiment of the hydraulic tensioning element 1 is shown. The tensioning element 1 comprises a bowl-shaped cylinder 2 which is produced by deep drawing and which is filled with a hydraulic fluid 4 . The piston 5 passes through the opening of the cylinder 2 , wherein the piston 5 made of stainless steel is radially supported by a guide ring 6 and sealed by a piston rod seal 7 which is arranged in a stationary manner In the housing of cylinder 2.

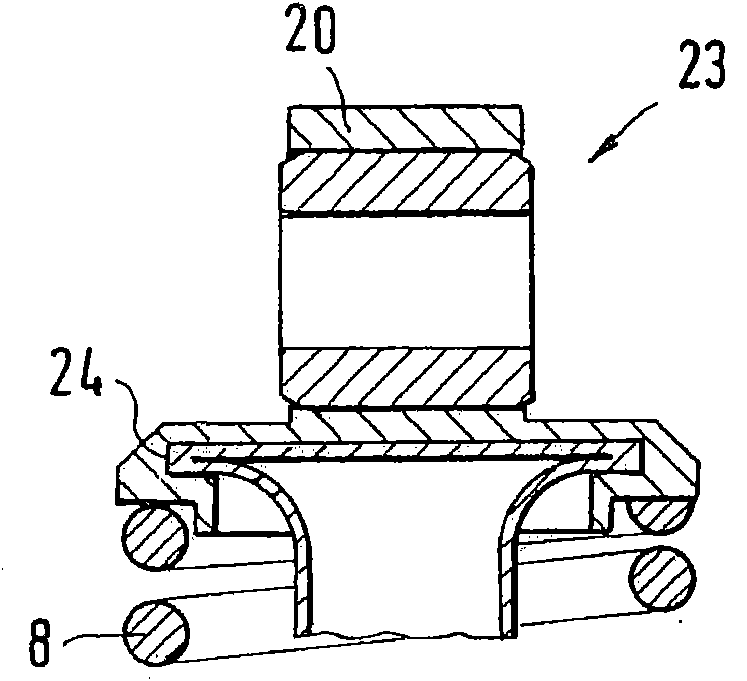

[0020] The cylinder 2 and the piston 5 are surrounded by a spring element in the form of a compression spring 8 which is supported on its end face by fastening elements in the form of spring support elements 9 , 10 which are supported on the base 11 of the piston 5 Or on the collar 12 of the cylinder 2. The fastening holes 13 , 14 are attached to the bottom 11 of the piston 5 or to the end face of the cylinder 2 , for example by gluing.

[0021] Located inside the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com