Walking claw with shockproof hammer accommodating function

An anti-vibration hammer and function technology, which is applied in the field of line inspection robots, can solve the problems of reducing the feasibility of inspection by line inspection robots, less types of obstacles that can be crossed, and short continuous operation time, so as to achieve precise and rapid control of the moving position of small wheels. , Easy and fast installation, good telescopic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

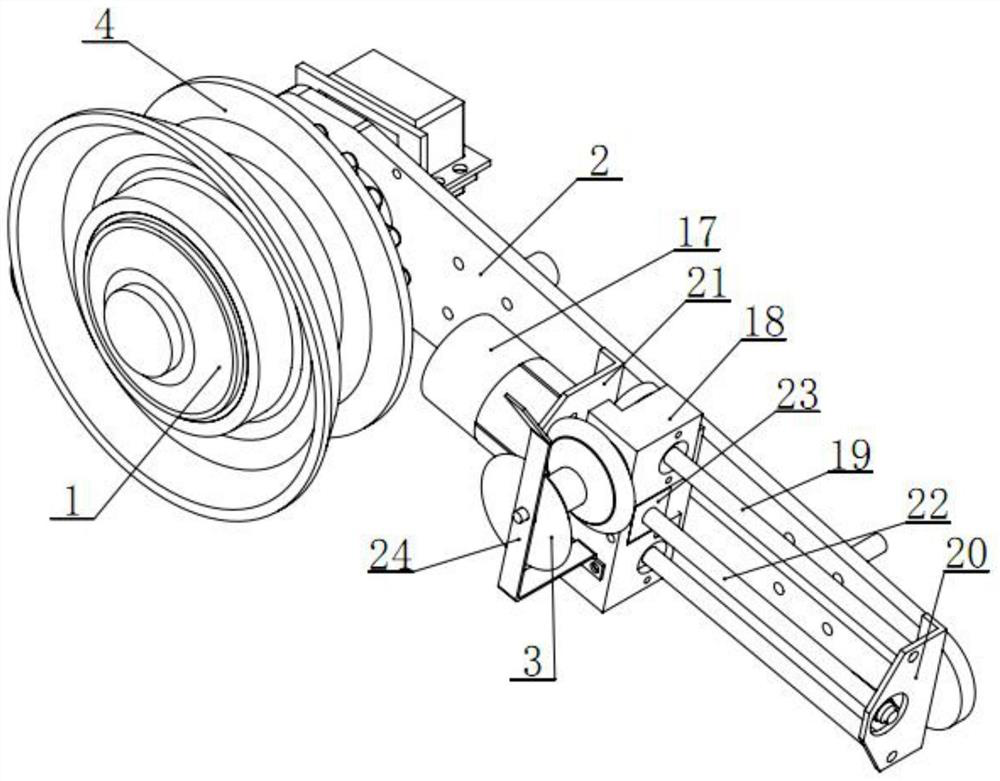

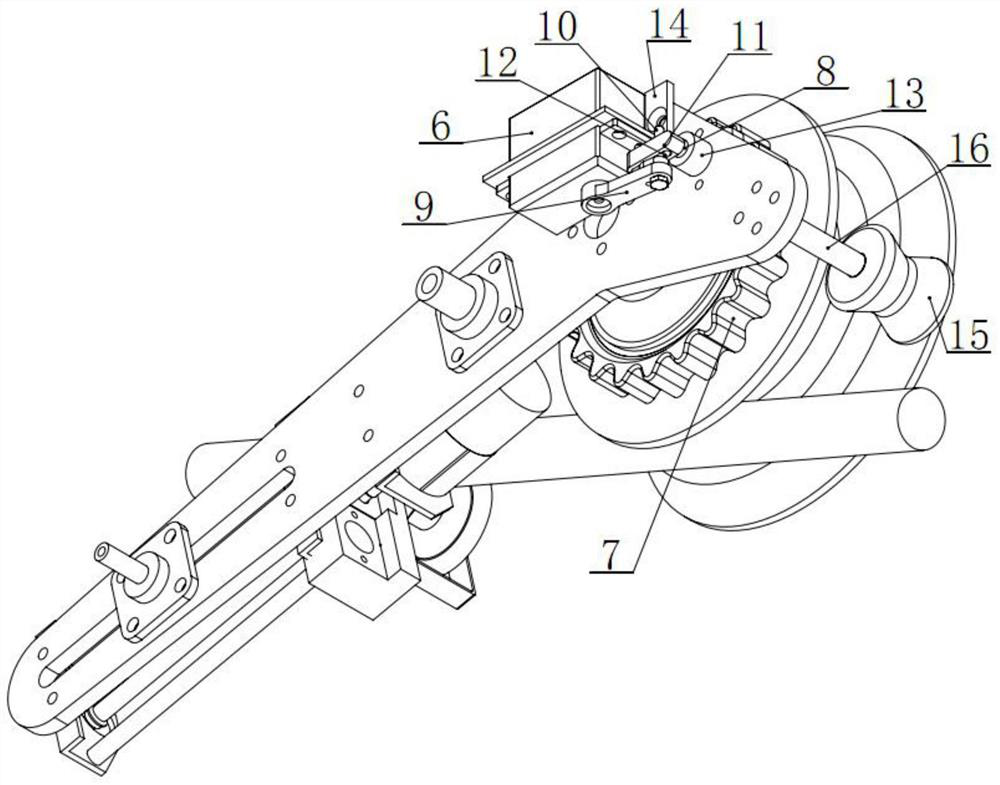

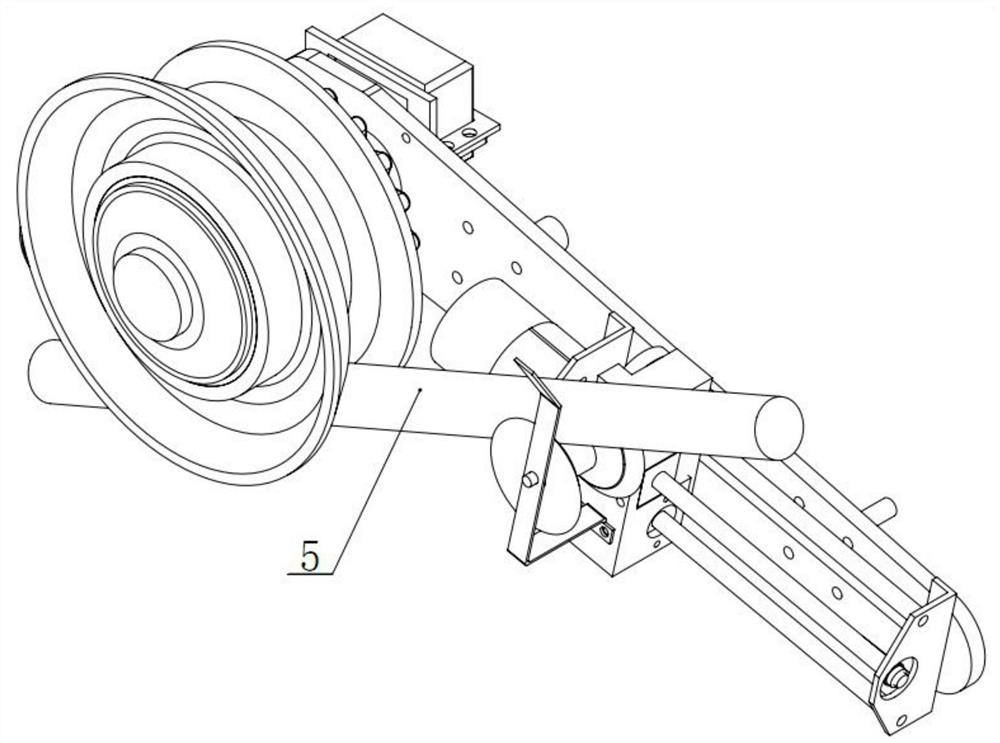

[0031] Embodiment 1: as Figure 1-6 As shown, a walking claw with the function of accommodating a shockproof hammer includes a hub motor 1, a side plate 2 and a small wheel 3. The hub motor 1 is covered with a rubber layer 4 with a cylindrical surface in the shape of an annular groove, and one end of the hub motor 1 is fixed. Connected to the front side of the side plate 2, the side plate 2 is also rotatably mounted with a small wheel 3 with a cylindrical surface in the shape of an annular groove, the upper side of the groove of the small wheel 3 and the lower side of the groove of the rubber layer 4 can contact the wire 5 , the small wheel 3 is connected to the telescopic device through the small wheel frame 24, the telescopic device is installed on the side plate 2, the side plate 2 is a bending structure, including a front inclined section and a rear inclined section, and the hub motor 1 is installed on the side plate bending The small wheel 3 is installed on the rear incli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com