Suction pad, friction stir welding device, and friction stir welding system

一种摩擦搅拌、接合装置的技术,应用在辅助装置、焊接/焊接/切割物品、吸杯等方向,能够解决设置空间变大等问题,达到提高接合速度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

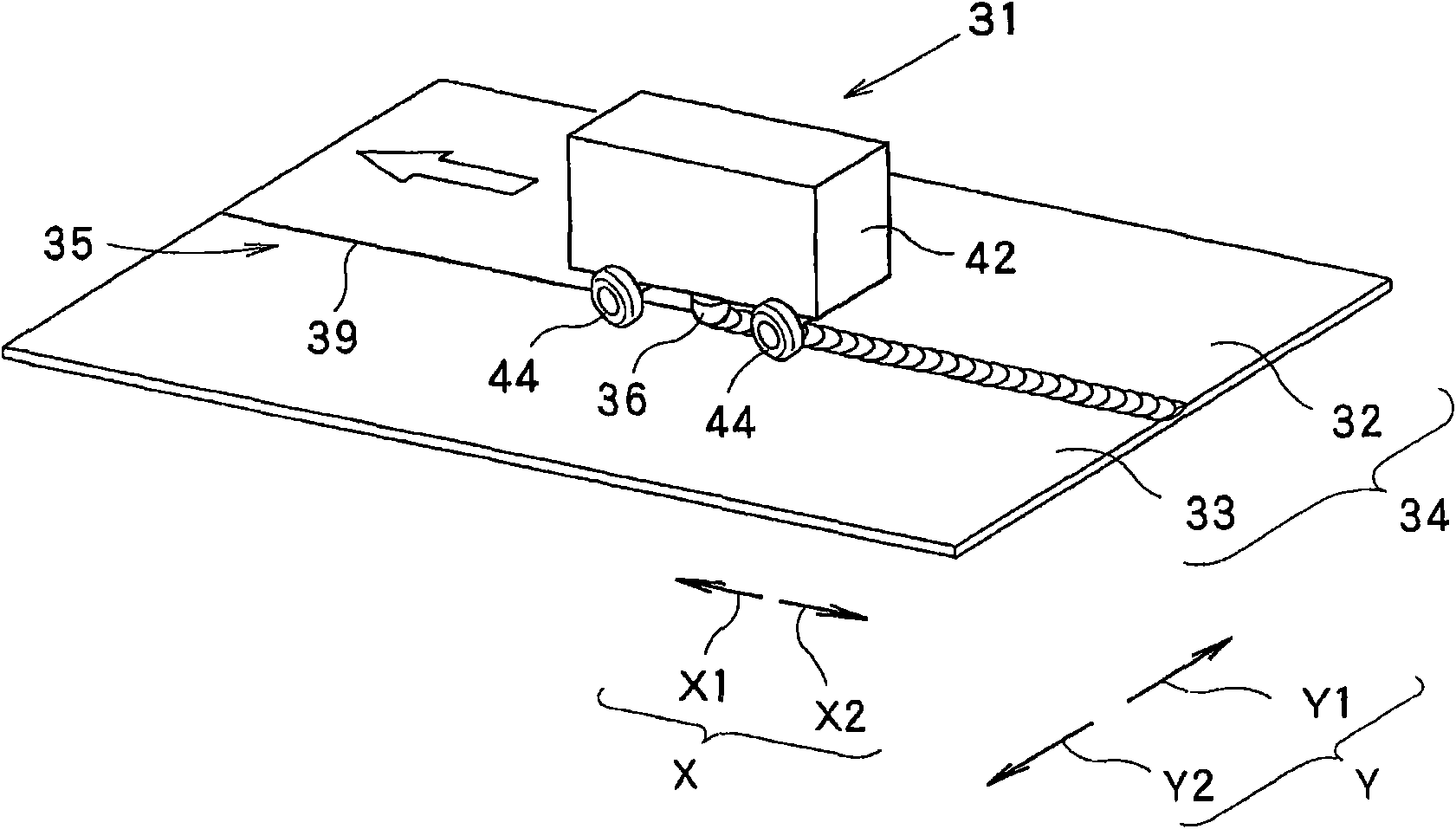

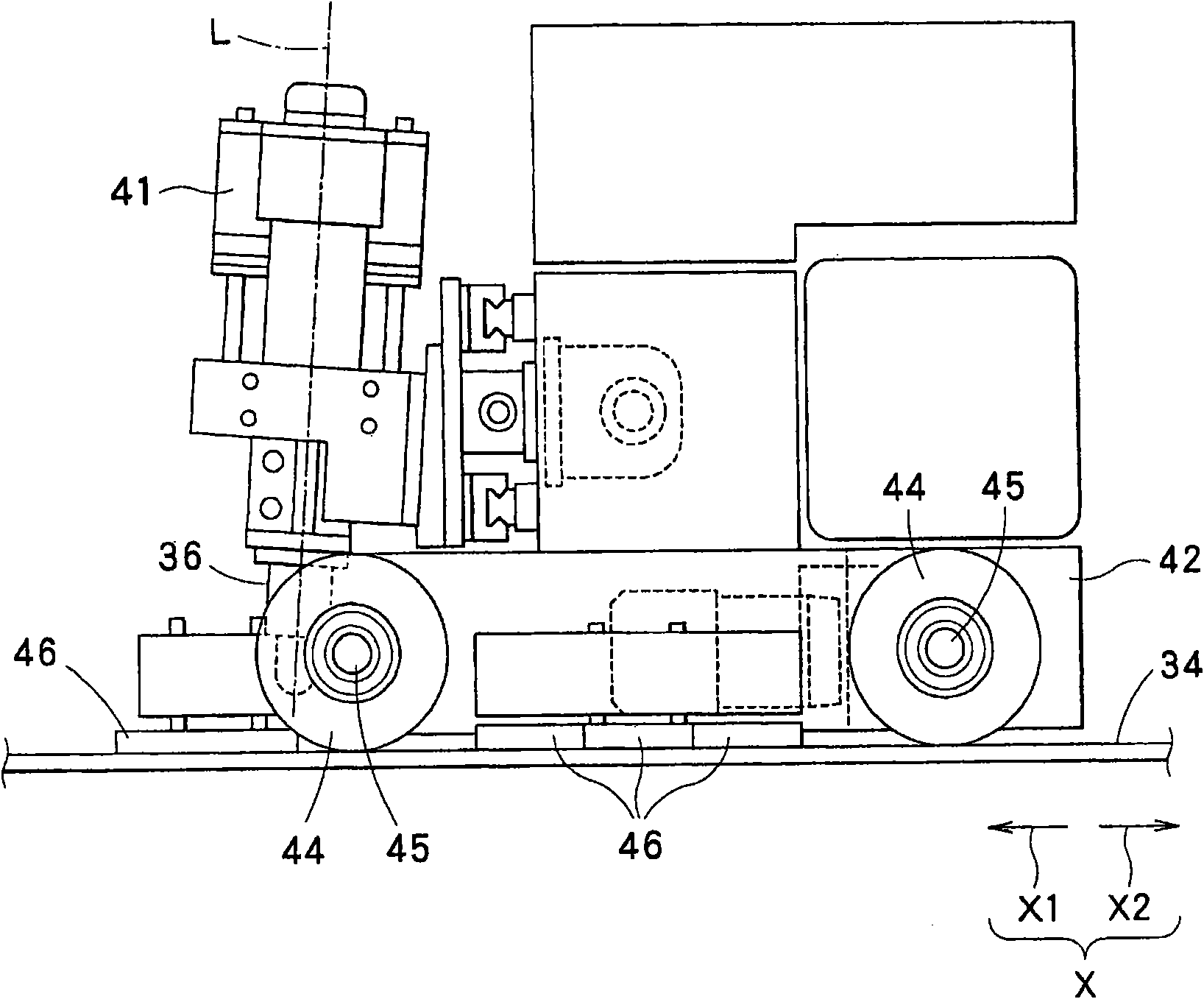

[0080] figure 1 It is a side view schematically showing a friction stir welding device (hereinafter, simply referred to as a welding device 31 ) according to an embodiment of the present invention. figure 2 It is a perspective view showing the running state of the joining device 31 .

[0081] The joining device 31 joins a to-be-joined object 34 for butting two to-be-joined objects 32 and 33 . On the object to be joined 34 , a seam portion 35 is formed at a joining site where the two objects to be joined 32 and 33 are butted together. The bonding device 31 moves the bonding tool 36 along the seam portion 35 to continuously bond the objects 32 and 33 to be bonded. The seam portion 35 has a joint line 39 as a boundary line of the respective objects 32 , 33 to be joined formed on the surface. The bonding wire 39 extends linearly in this embodiment.

[0082] A cylindrical bonding tool 36 is attached to the bonding device 31 , and friction stir welding is performed using the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com