High-power brushless double-fed motor variable frequency speed control system and starting method thereof

A technology of variable frequency speed regulation and motor, which is applied in the direction of motor generator/starter, single motor speed/torque control, AC motor control, etc., and can solve problems such as easy sparks, high cost of frequency converter, and reduced motor reliability , to achieve cost saving, stable start-up process, safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing.

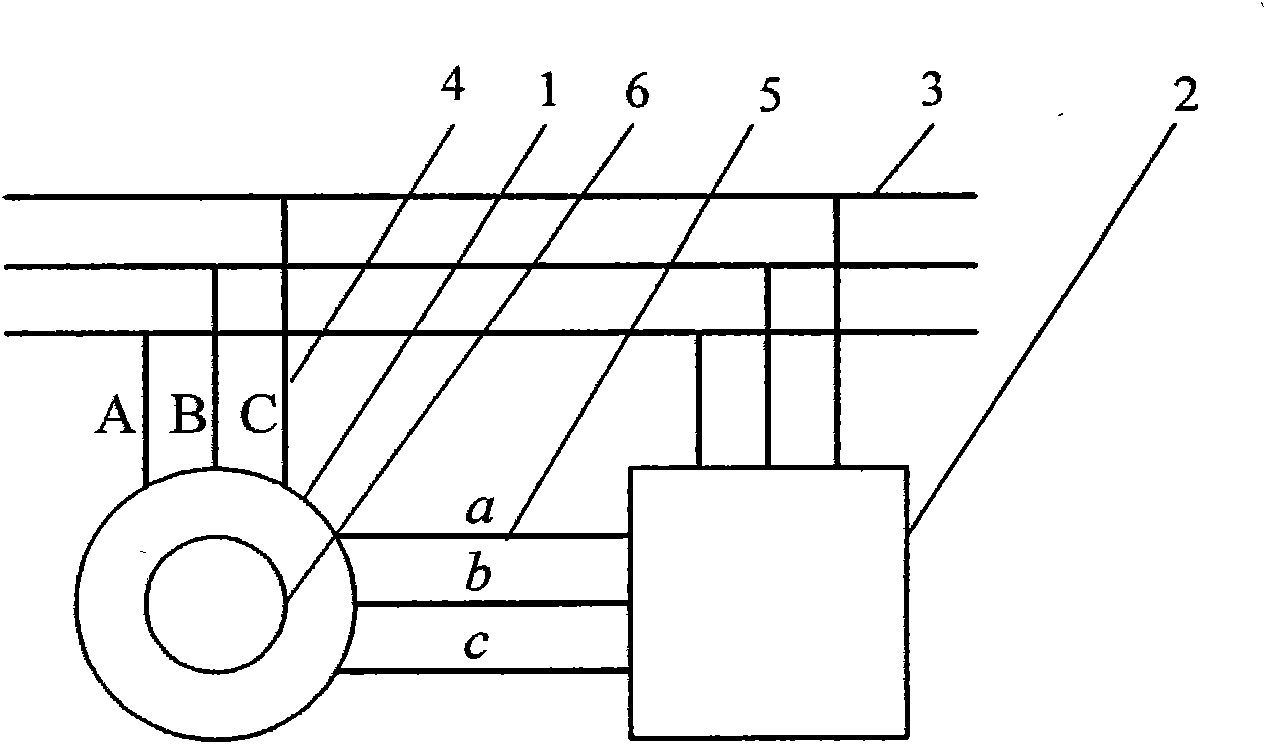

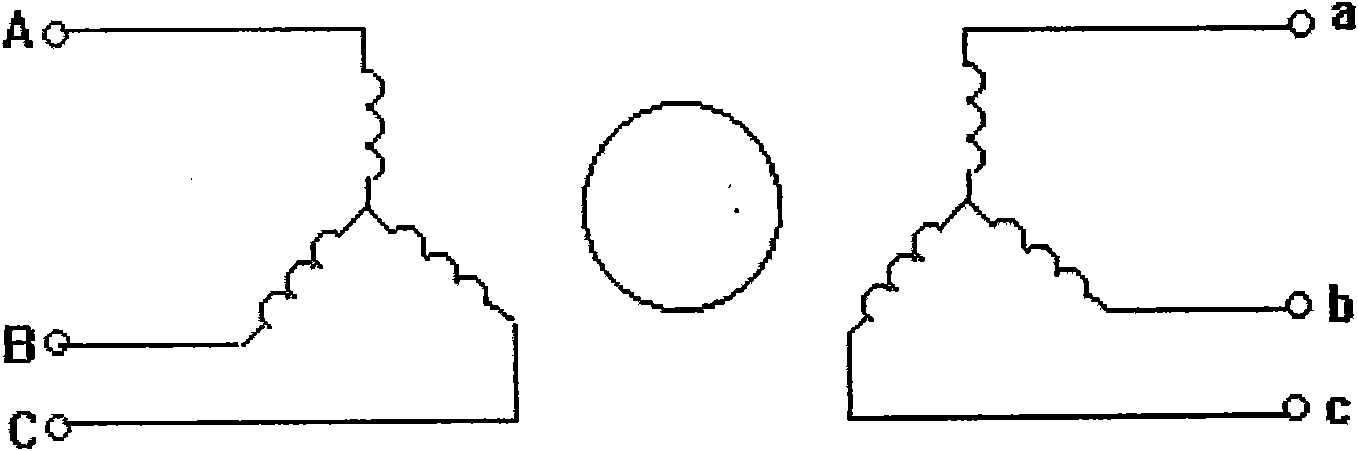

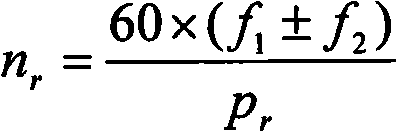

[0013] Such as figure 1 and 2 The shown high-power brushless doubly-fed motor frequency conversion speed regulation system of the present invention includes a brushless doubly-fed motor 1 and a frequency conversion controller 2, the stator power winding 4 of the brushless doubly-fed motor 1 is directly connected with the power frequency grid 3; the stator The control winding 5 is connected with the frequency conversion controller 2; the frequency conversion controller 2 is directly connected with the power frequency grid 3; the stator power winding 4 and the stator control winding 5 are star-connected; the rotor of the brushless doubly-fed motor 1 is a reluctance rotor 6; The number of poles of the stator power winding 4 is 2p, the number of poles of the stator control winding 5 is 2q, and the number of poles of the reluctance rotor 6 is p r =p+q, the brushless double-fed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com