Method and device for winding coils

A technology of a winding device and a winding method, which is applied in the direction of coil manufacturing, etc., can solve the problems of time-consuming and laborious shaping operations, and achieve the effects of improving productivity and shortening production takt time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, embodiments of the present invention will be described based on the drawings.

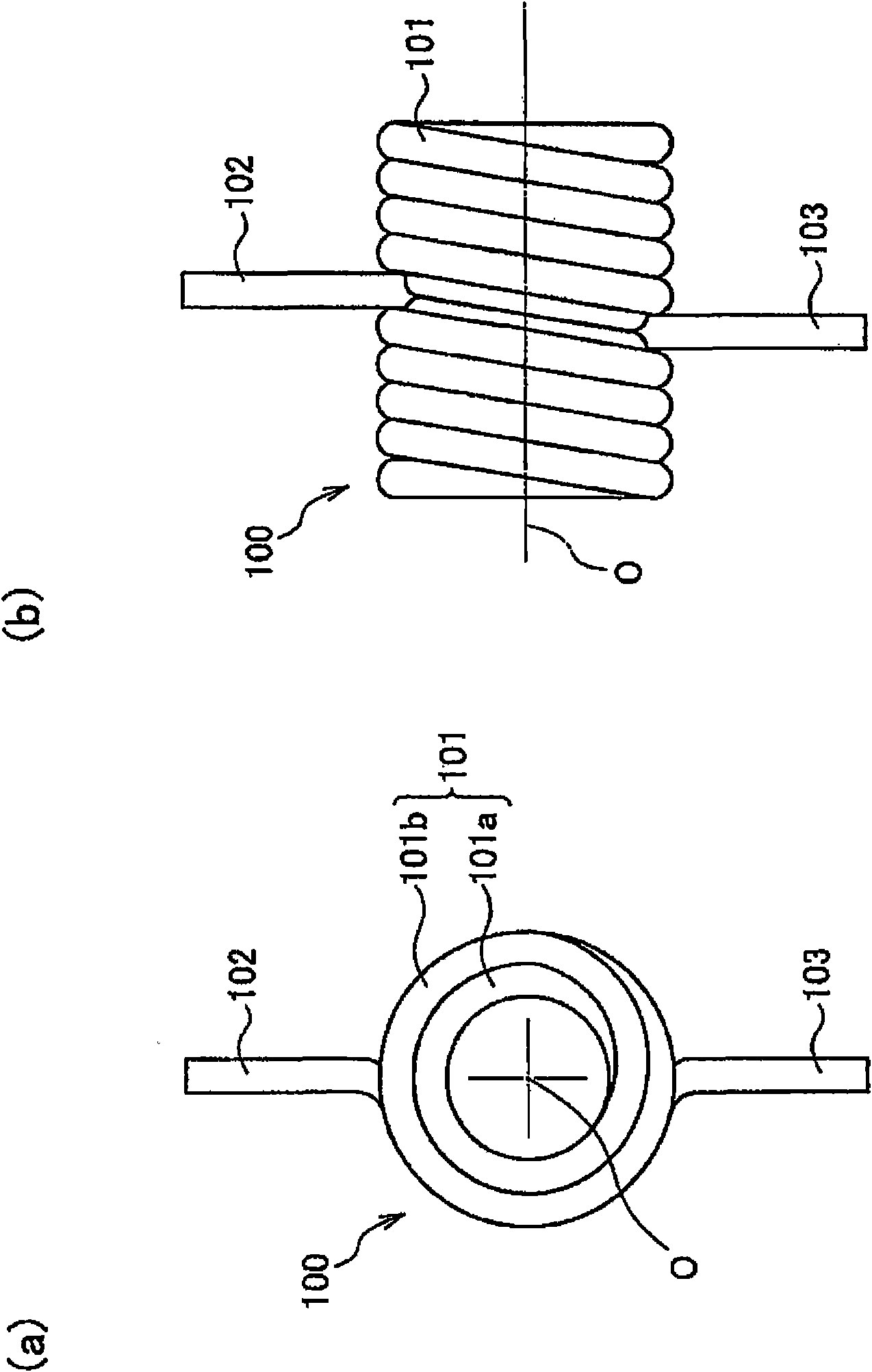

[0023] figure 1 (a) is a side view of the double outer winding coil (coil) 100, and (b) is a front view of the double outer winding coil 100. The double outer winding coil 100 has a coil portion 101 around which the wire 2 is spirally wound, and has a first lead portion 102 and a second lead portion 103 as a lead portion constituted by the wire 2 extending from the coil portion 101 .

[0024] The coil part 101 has the 1st layer winding part 101a and the 2nd winding part 101b. The first lead part 102 and the second lead part 103 are shaped such that they are respectively bent from the second-layer winding part 101b of the coil part 101, and extend from the winding center axis O in a radial direction with an angular difference of 180°.

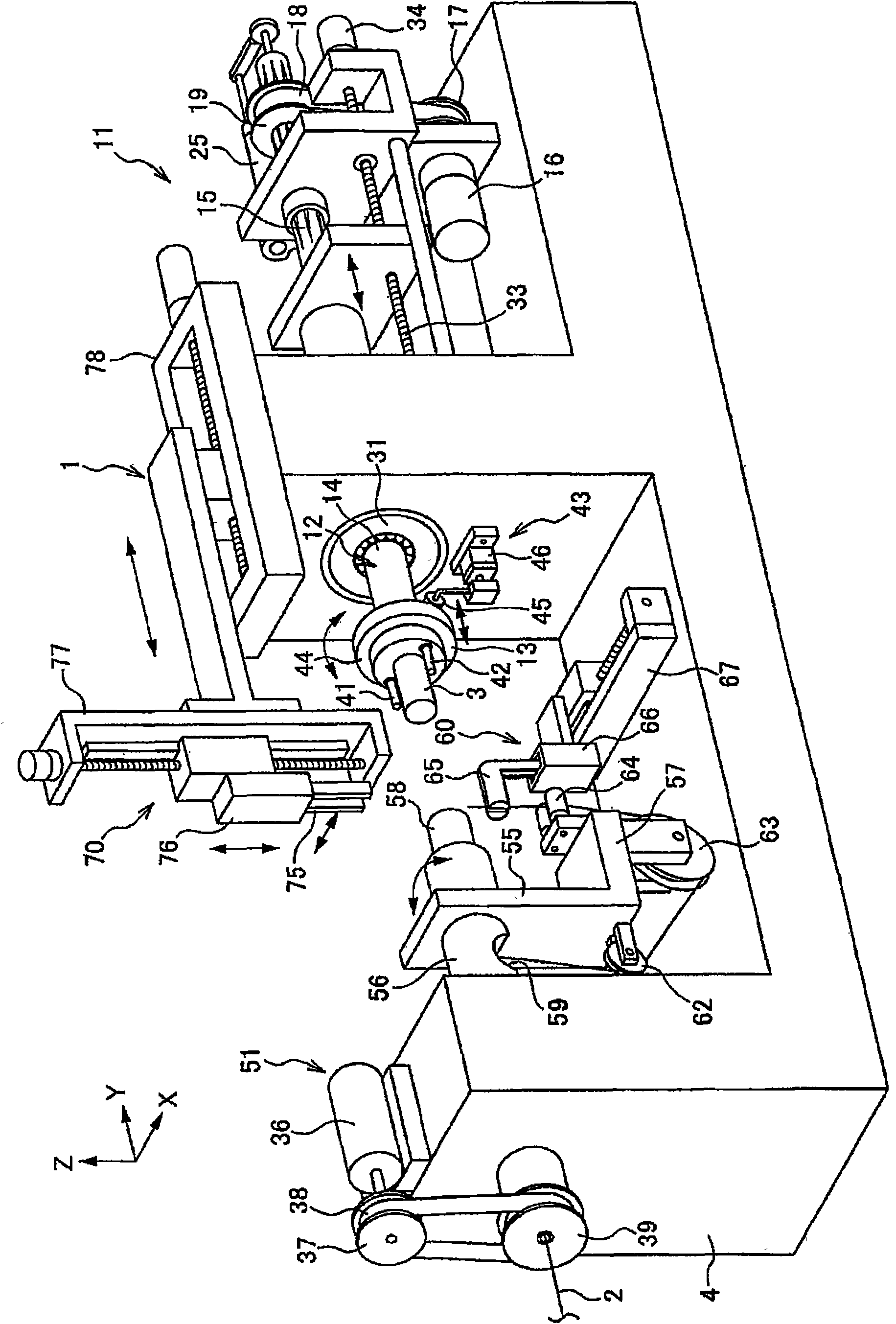

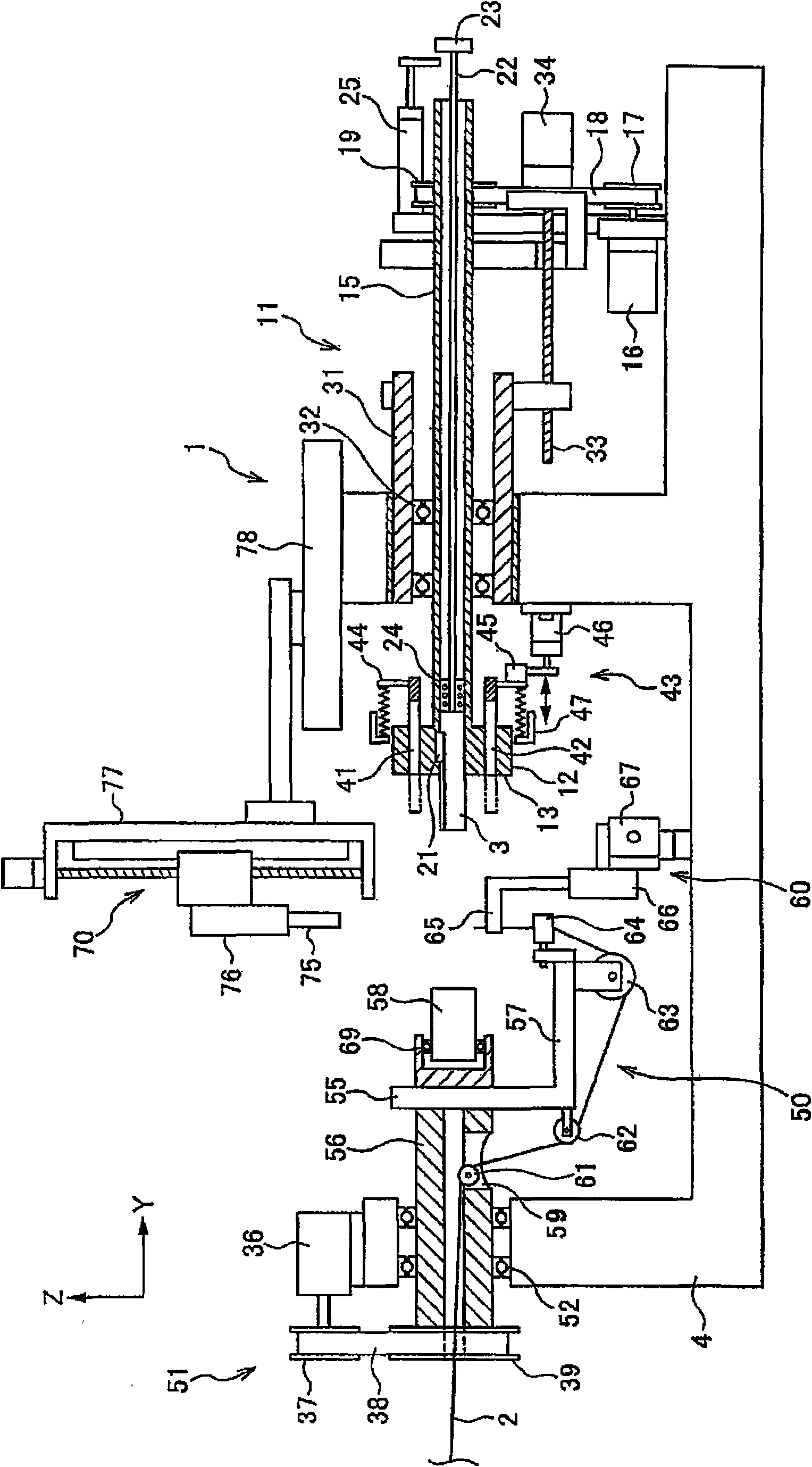

[0025] figure 2 It is a perspective view showing a schematic configuration of a coil winding device (double outer coil winding device) 1 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com