Method for realizing gang control of three Z axes in numerical control machine system

A CNC machine tool and linkage control technology, which is applied in the motion control of CNC machine tool system and the field of CNC machine tool system control, can solve the problems of large manpower consumption, achieve the effects of increasing work efficiency, reducing processing time, and effective control methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

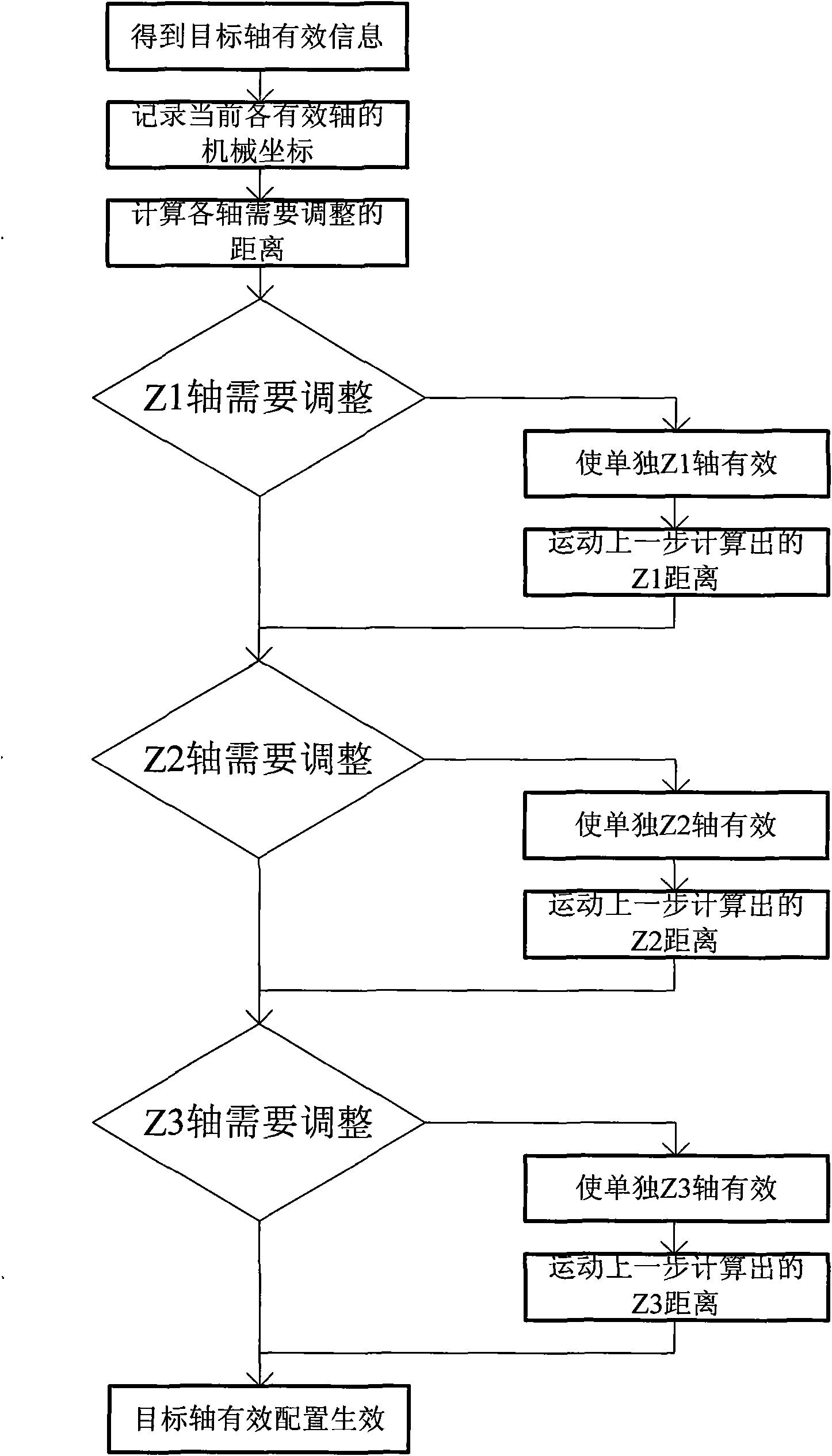

[0026] The method of realizing the linkage control of three Z-axes in the CNC machine tool system is based on the principle that when the three Z-axes are adjusted to have the same workpiece coordinates, their motion control is consistent for the same workpiece, so that a The information calculated by the axes can control the effects of the three axes at the same time. The actual movements of the three axes are all correct. At this time, it is only necessary to show the user a suitable interface. The same effect of workpiece coordinates can be achieved by sequentially adjusting individually.

[0027] The main feature of this method for realizing three Z-axis linkage motion control in the CNC machine tool system is that only the motion control in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com