Preparation method of self-assembled superlattice materials of titanium dioxide nano rod

A technology of titanium dioxide and nanorods, applied in the fields of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

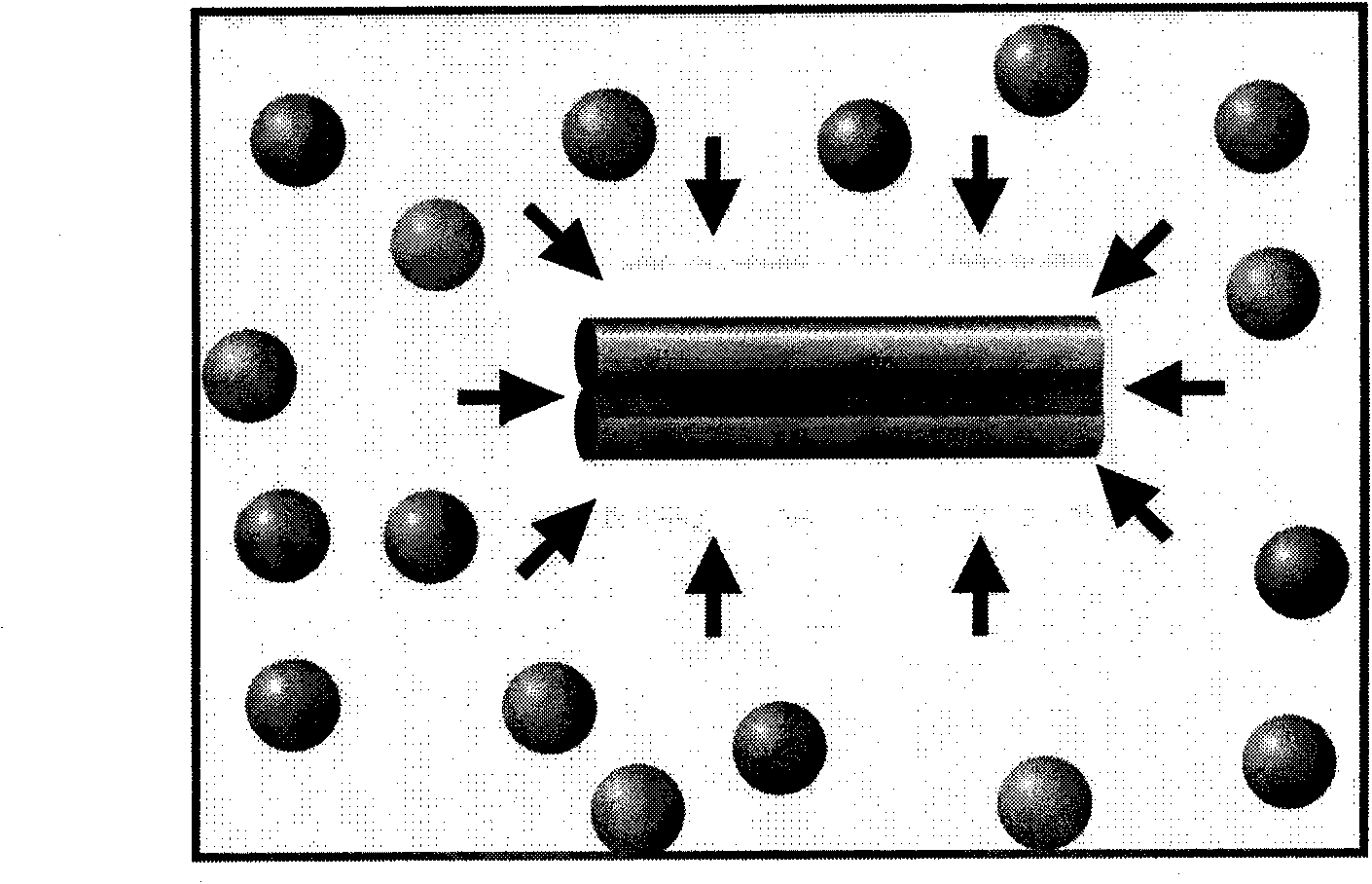

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Whole TiO 2 The synthesis reaction was carried out in an anhydrous and oxygen-free Schlenk apparatus. First, a mixture of 4 ml of oleic acid (Aldrich, purity 95%) and 5 ml of octadecene (Aldrich, purity 97%) was stirred and heated at 100° C. for 1 hour to remove residual water and oxygen. Then 0.3 ml of n-butyl titanate (Aldrich, purity 99%) was injected into the above mixture and kept at 100° C. for 20 minutes. After 20 minutes, the temperature of the synthesis apparatus was raised to 260° C. and kept there for 10 minutes. Then 2 mL of oleylamine (Aldrich, 98% purity) was injected rapidly and the solution was vigorously stirred for 1.5 hours. After the solution is cooled, add 6 ml of a mixture of n-hexane and acetone with a volume ratio of 1:1 to precipitate TiO 2 Nanorod flocculent precipitation, and then centrifuged at 4000 rpm to obtain yellow TiO 2 nanorods, the TiO 2 Can be dispersed in non-polar solvents (such as n-hexane, toluene, etc.) to form a...

Embodiment 2

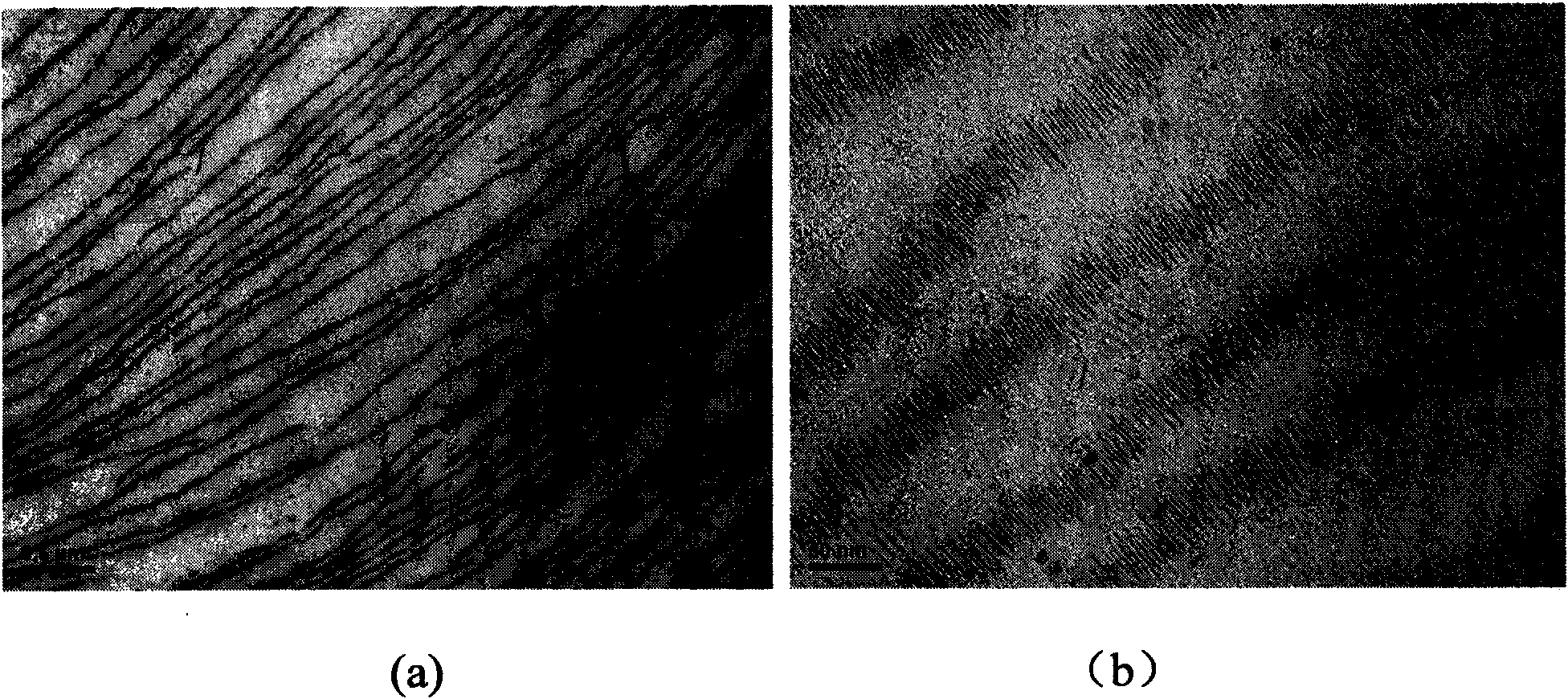

[0024] Embodiment 2: Synthetic TiO 2 The process of the nanorods is the same as in Example 1. Subsequent addition of pure oleic acid volume: TiO 2 When the solution volume is about 1:5, the concentration of oleic acid in the final solution is about 5.2×10 -4 In the case of mol / mL, the slow evaporation of the solvent can be obtained as image 3 The Ribbon structure shown.

Embodiment 3

[0025] Embodiment 3: Synthetic TiO 2 The process of the nanorods is the same as in Example 1. Subsequent addition of pure oleic acid volume: TiO 2 When the solution volume is about 1.5:5, the concentration of oleic acid in the final solution is about 7.8×10 -4 mol / ml, by slow evaporation of the solvent can be obtained as Figure 4The ribbon-shaped (Ribbon) structure and the honeycomb (Honeycomb) structure coexisting situation shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com