Ventilating system of painting house

A technology of ventilation system and spray booth, which is applied in the directions of ventilation system, space heating and ventilation, space heating and ventilation details, etc., can solve the problems of small space of spray booth, waste of hydraulic resources, and increased power consumption of fans, etc. Complete oil mist filtration, preventing paint mist from rising, and stable airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

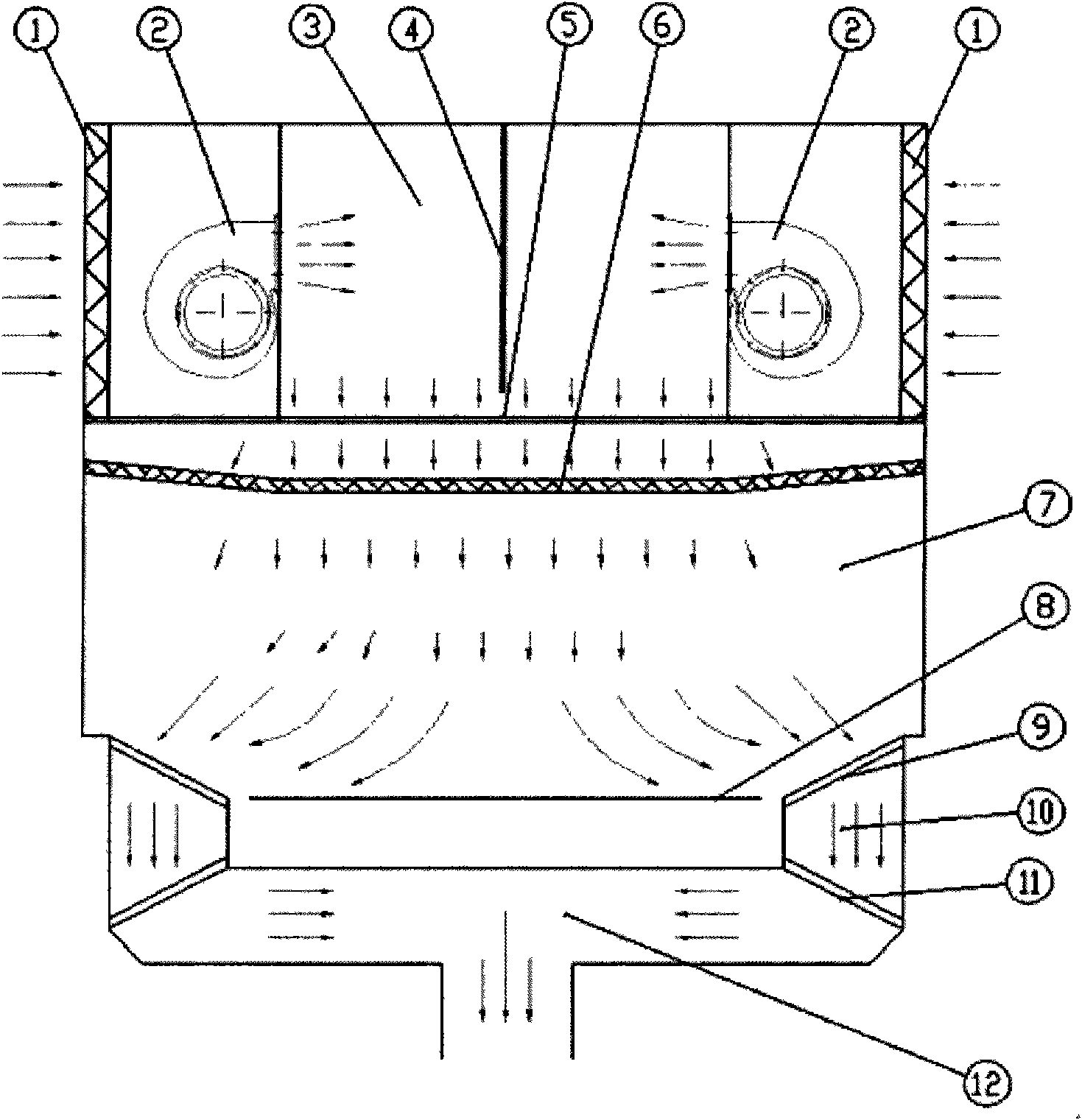

[0009] Embodiment 1: with reference to attached figure 1 . Ventilation system of spraying room, which includes fan 2, filter system, and workpiece table 8. The upper part of the distribution network 5 in the spraying room 7 is divided into two left and right air pressure boxes 3 through the windshield 4, and the air pressure box 3 is equipped with two fans. 2. The fan outlet faces inwardly to the wind pressure box 3 . The outermost side of the fan 2 is the primary dust filter 1, the lower part of the shunt 5 is equipped with a secondary dust filter 6, the workpiece table 8 on the opposite side is located at the bottom of the spray booth 7, and the upper ends of the air outlets 10 on the left and right sides are respectively obliquely installed with filter paper 9, and the lower ends A secondary filter screen 11 is installed obliquely, and an exhaust air duct and an exhaust fan 12 are installed at the bottom of the spray booth. After the fan 2 is started, the outside air is s...

Embodiment 2

[0010] Embodiment 2: On the basis of embodiment 1, the ventilation method of the spraying room ventilation system makes the top of the spraying room produce uniform wind pressure, effectively prevents the paint mist generated in the spraying process from rising, and simultaneously makes the dust in the spraying room as small as possible. The possible reduction, combined with the exhaust system of the spraying room, makes the airflow in the spraying room more stable. The exhaust part adopts multi-stage and multi-form dry filtration methods to filter the oil mist more thoroughly. The filter paper is a double-layer filter paper with honeycomb holes, and the labyrinth filtering method is used to block most of the paint in the paint mist on the filter paper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com