Electronic component and manufacture method thereof

A technology of electronic components and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] An electronic component and its manufacturing method according to one embodiment of the present invention will be described below.

[0021] (composition of electronic components)

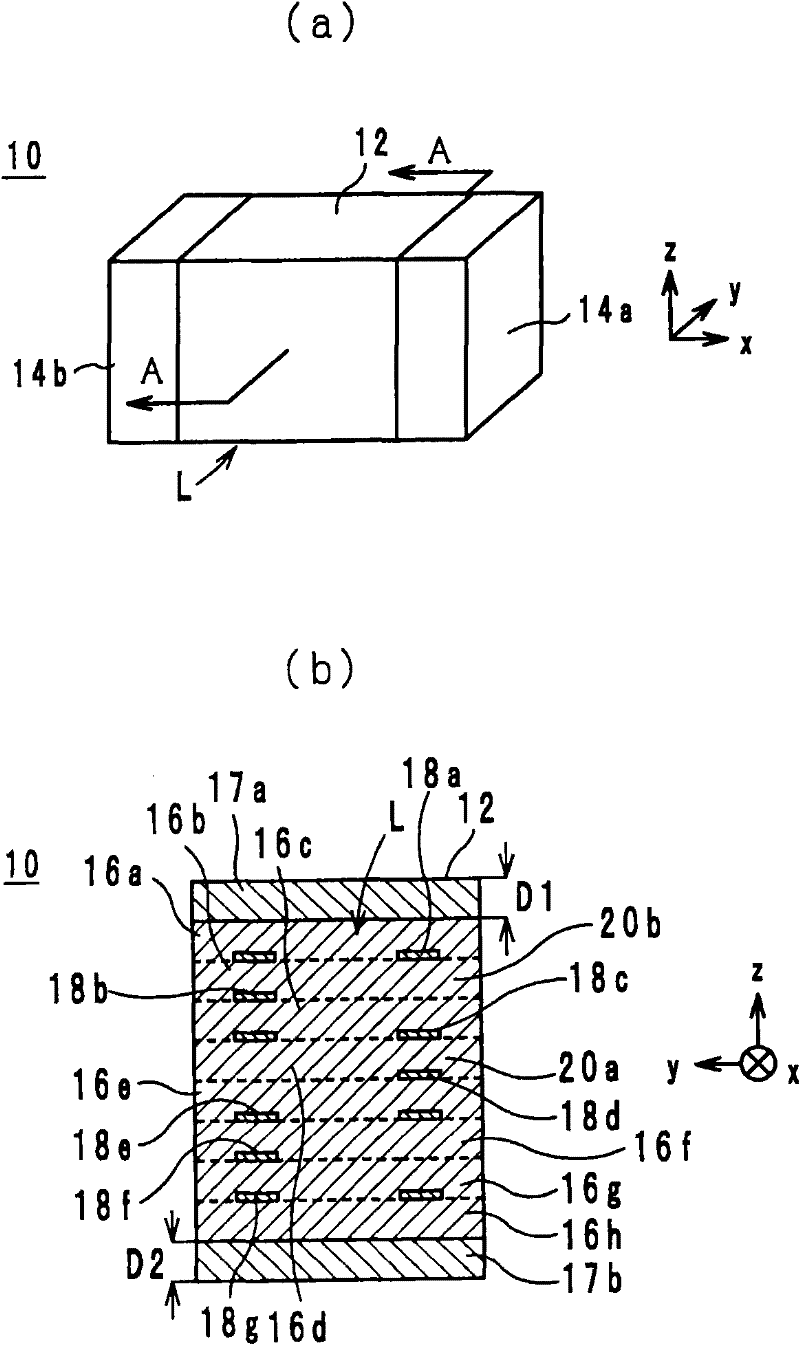

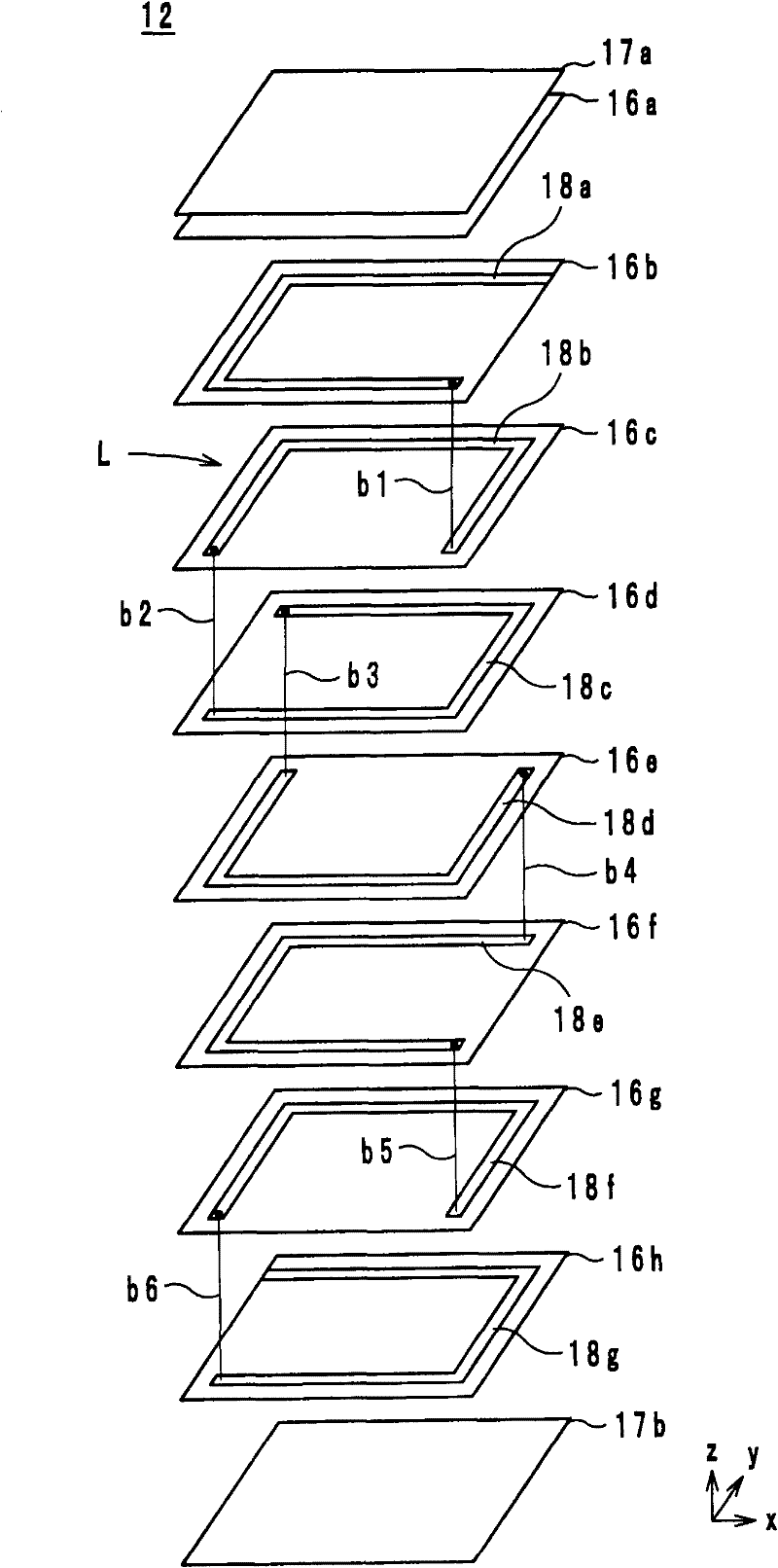

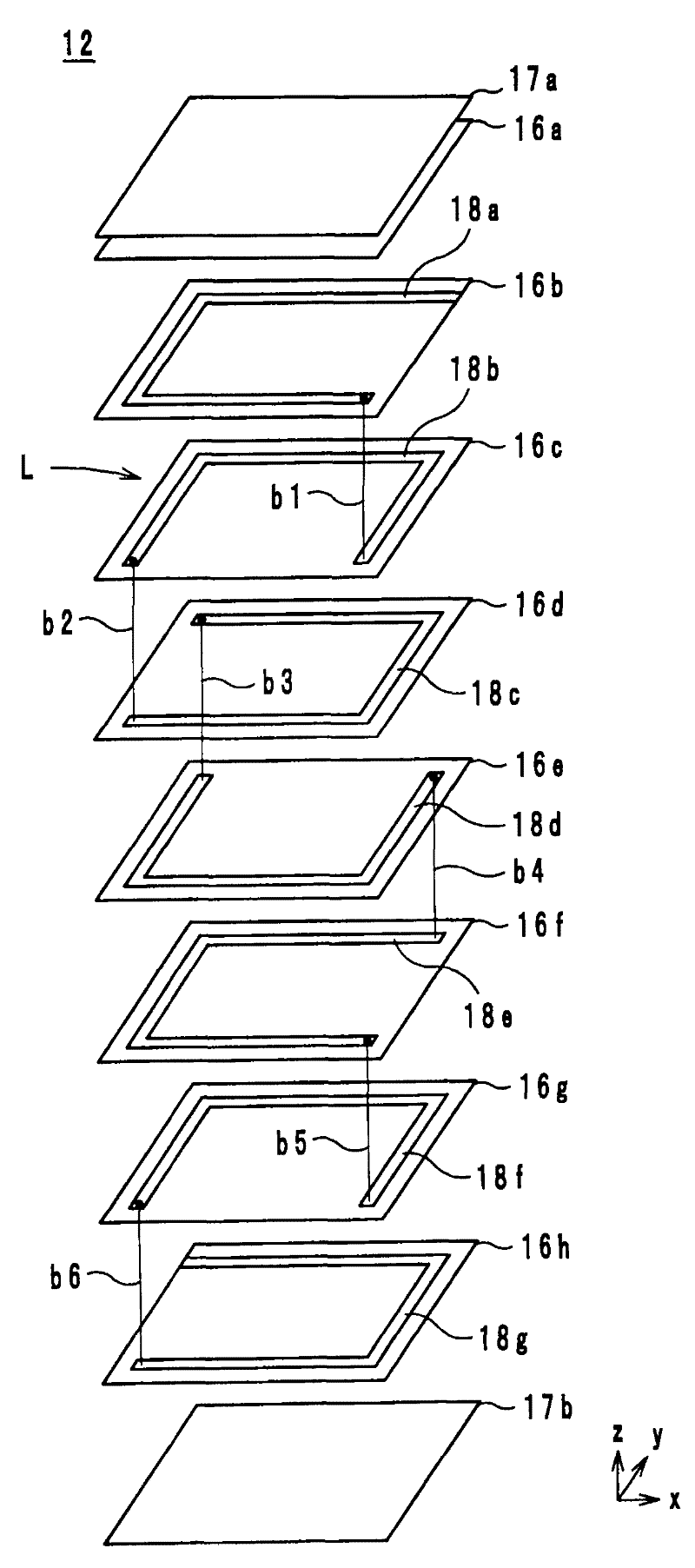

[0022] figure 1 (a) is a perspective view of the appearance of the electronic assembly 10; figure 1 (b) is an A-A sectional structural diagram of the electronic module 10 . figure 2 It is an exploded perspective view of the laminated body 12 of the electronic module 10 . Hereinafter, the stacking direction of the electronic component 10 is defined as the z-axis direction; the direction along the long side of the electronic component 10 is defined as the x-axis direction; and the direction along the short side of the electronic component 10 is defined as the y-axis direction. exist figure 1 In (b), the boundary line of each layer is shown by the dotted line, but in reality, there may be no recognizable boundary line.

[0023] like figure 1 As shown in (a), the electronic component 10 in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com