Micro slip control method during lock-up meshing of wet clutch

A wet clutch and control method technology, applied in the field of control, can solve the problems of increased fuel consumption, large shift shock, large energy loss, etc., and achieve the effects of improving reliability and service life, reducing shift shock, and small energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

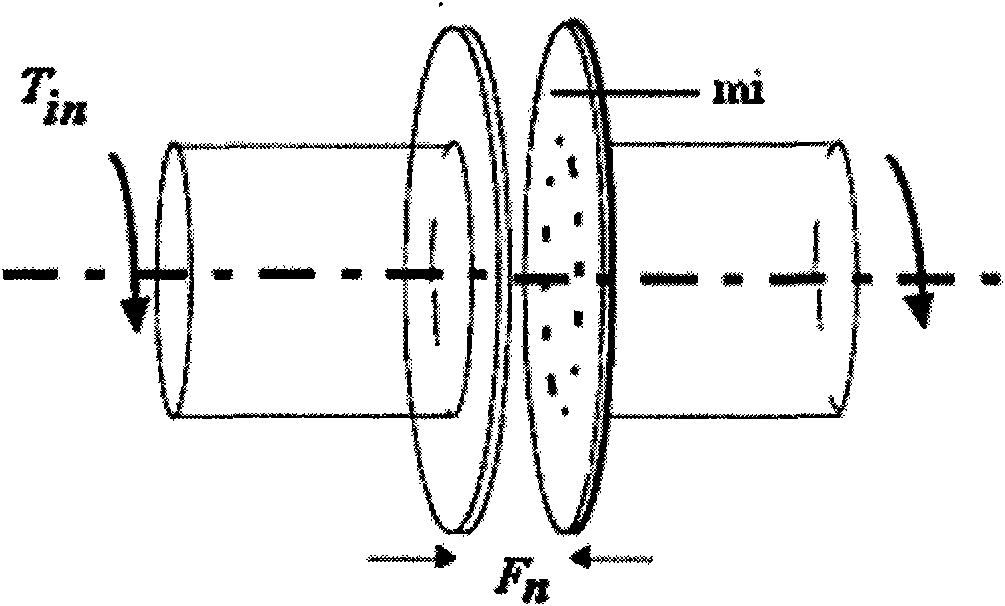

[0031] The micro-slip friction control method of the present invention when the wet clutch is locked and engaged will be described in detail below with reference to the accompanying drawings.

[0032] Aiming at the deficiencies and defects of the existing control strategies, the present invention proposes a strategy of micro-slip friction control clutch lock-up and engagement.

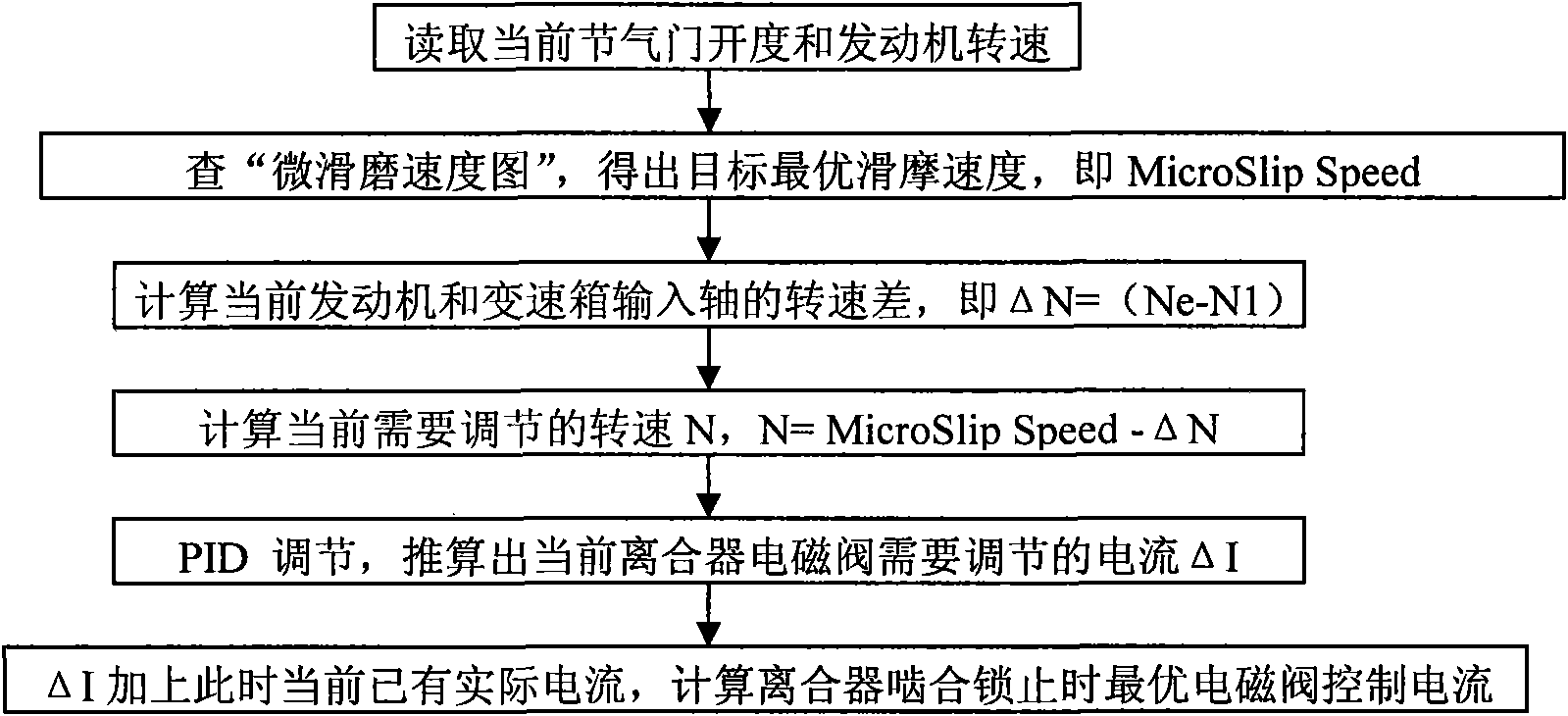

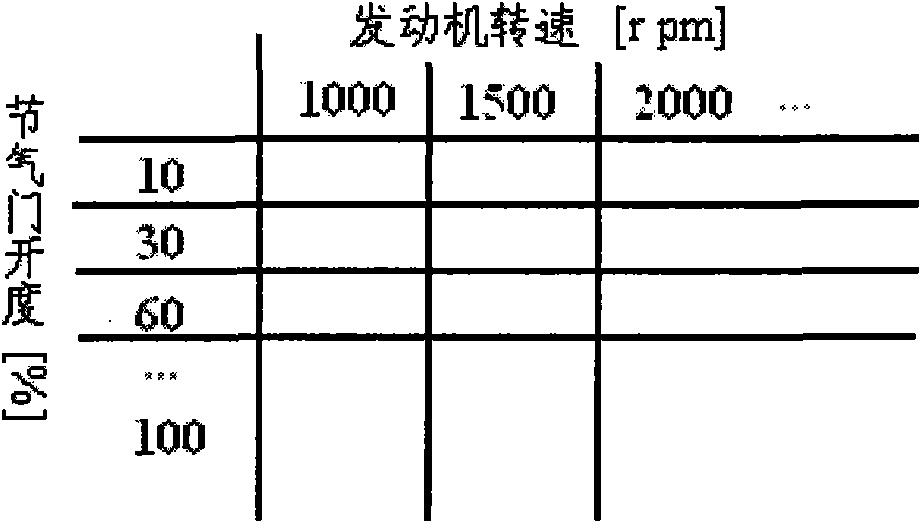

[0033] Micro-slip speed is a dynamic quantity, mainly determined by the current throttle opening and engine speed. Before designing the control strategy, it is necessary to conduct theoretical calculations and a large number of experiments on the wet clutch used to obtain the following: image 3 and Figure 4 The microslip friction velocity diagram shown. When actually driving, according to the current throttle opening and the engine speed, look up the table to obtain the optimal sliding speed, as a reference in the strategy, and then calculate the optimal current of the output solenoid valve, so as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com