Nano rotor drum oil-collecting device

A kind of drum and nano technology, applied in the direction of grease/oily substance/float removal device, liquid separation, separation method, etc. High cost performance, good lipophilic and hydrophobic properties, and the effect of large oil collection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

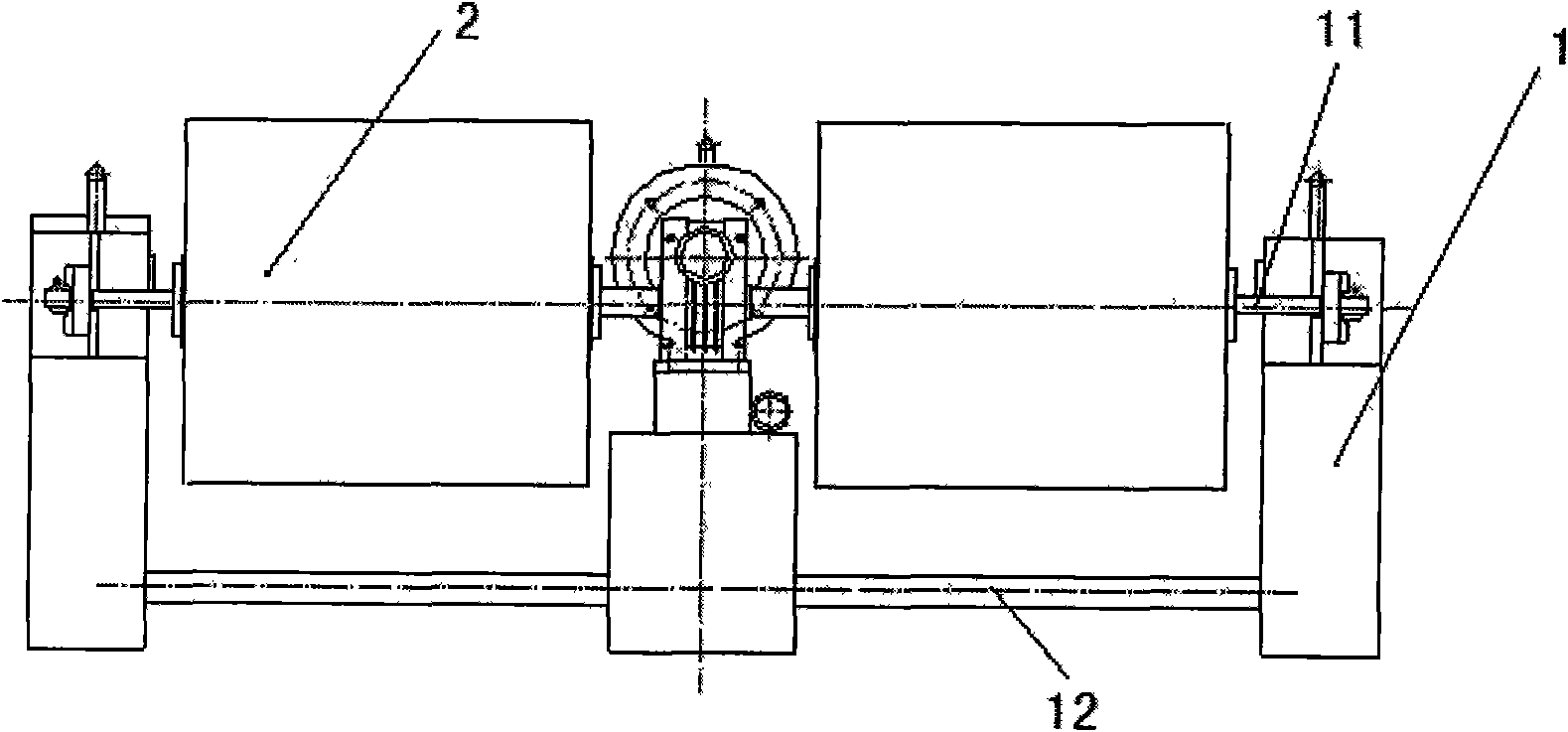

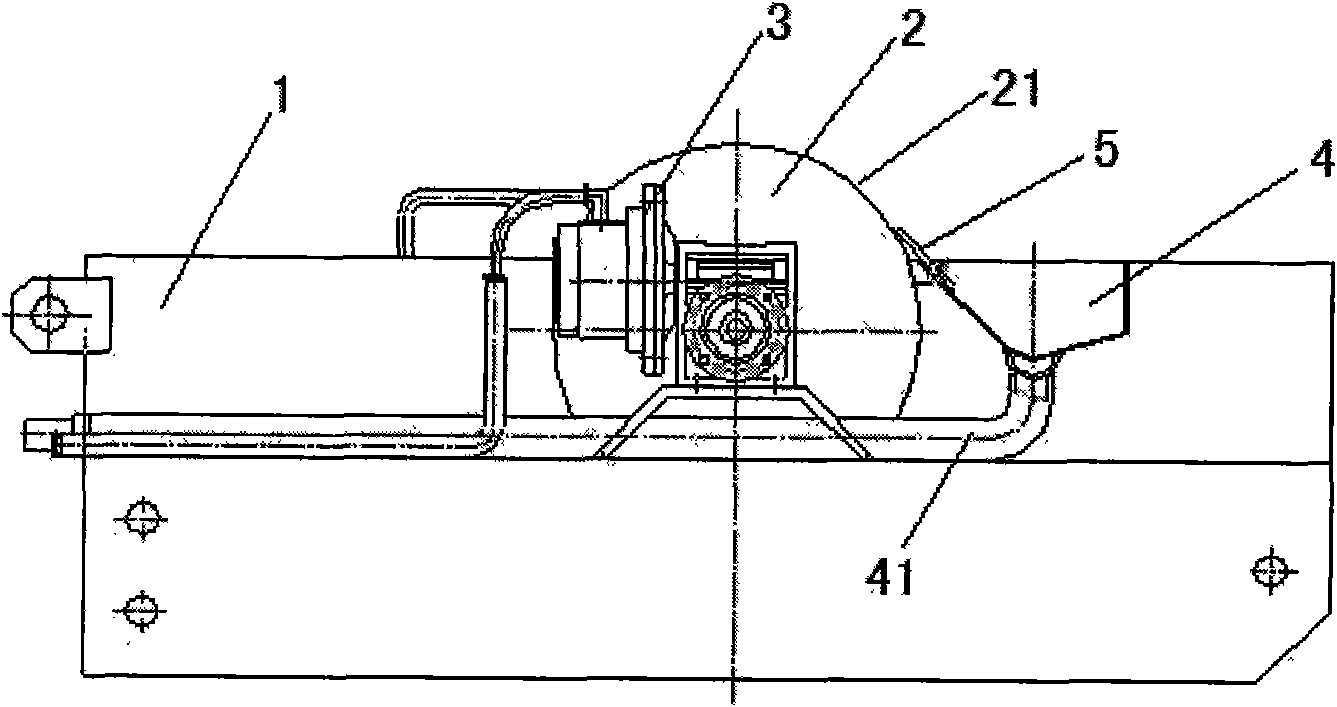

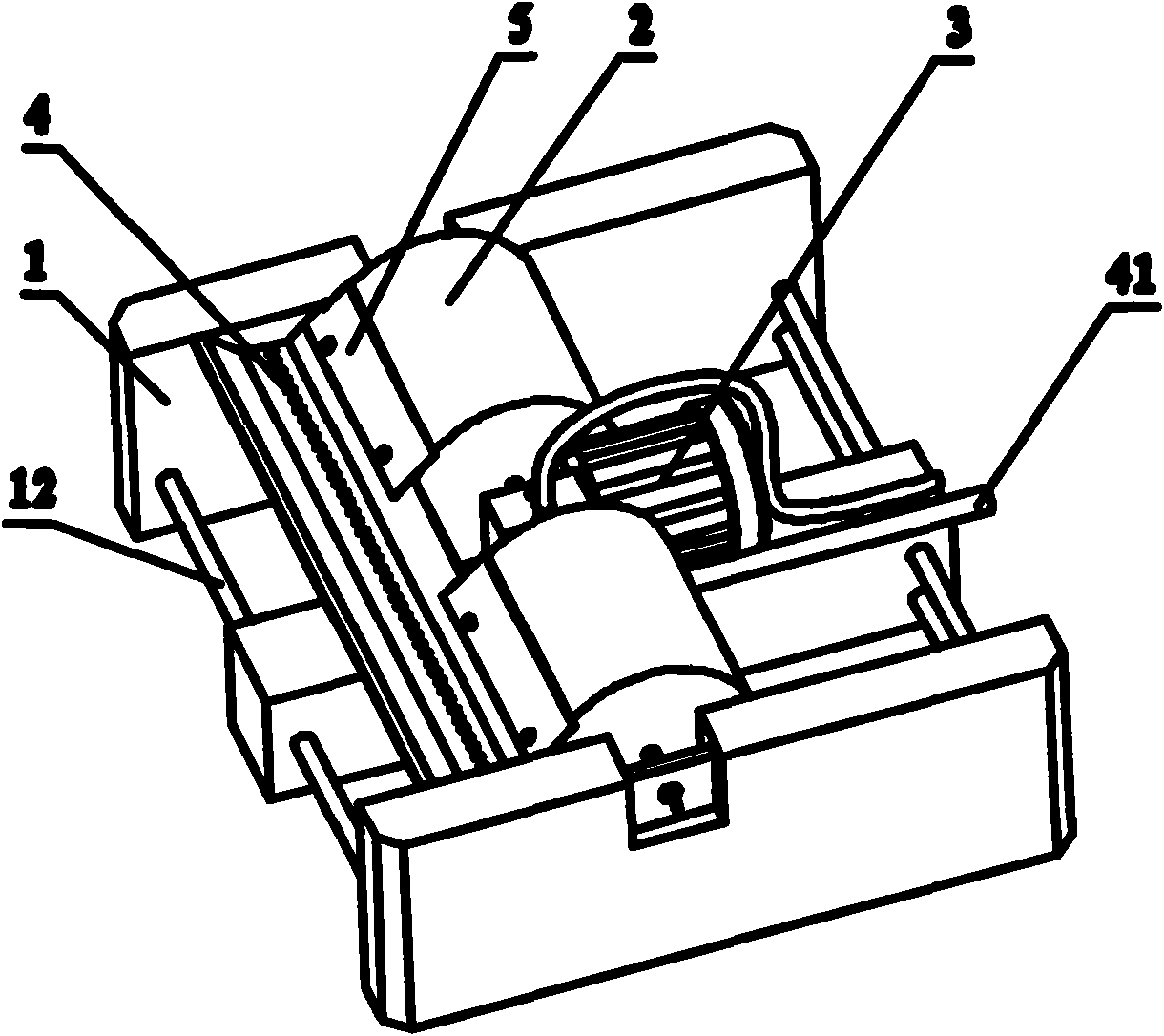

[0026] like figure 1 , figure 2 Shown, a kind of nano-drum oil collection device, it comprises a frame 1 and several drums 2, and drum 2 axis is arranged on frame 1 and rotates around shaft 11, and the surface of drum 2 is coated with one deck nano layer 21 , the nano-layer 21 is made of nano-polymer material, which has good lipophilic and hydrophobic properties. When the drum 2 is in contact with the oily wastewater, it can ensure that the oil droplets in the wastewater are well adsorbed and not the water droplets. The collected oil slick Almost no water, high oil collection efficiency, and strong adaptability to different oil pollution; the nano-polymer material in the nano-layer 21 is a nano-polymer material with lipophilic and hydrophobic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com