Method of gasifying gasification fuel and apparatus therefor

一种气化燃料、气化装置的技术,应用在气化燃料的气化领域,能够解决不能得到高气化效率等问题,达到提高生成效率、提高气化效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

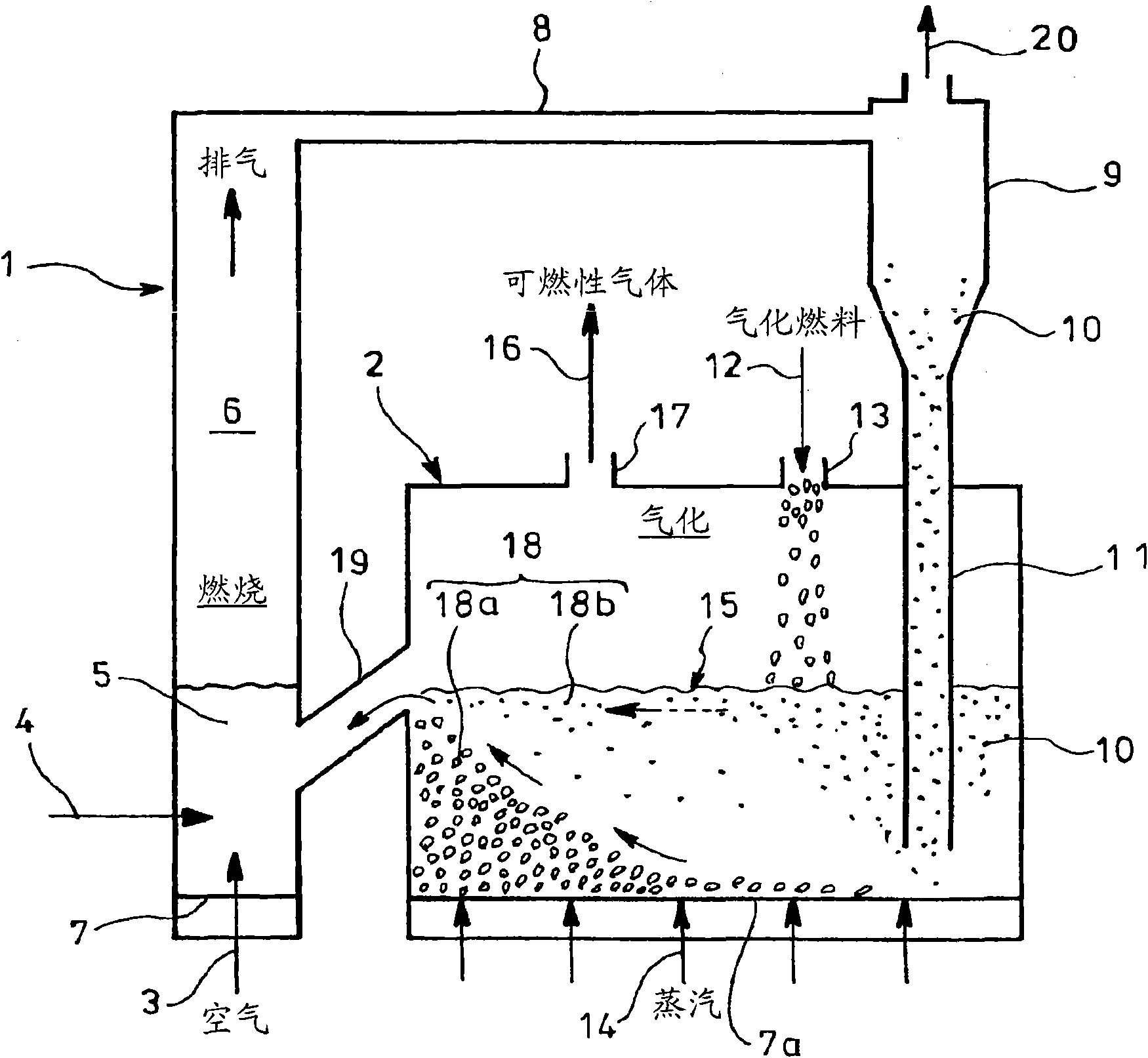

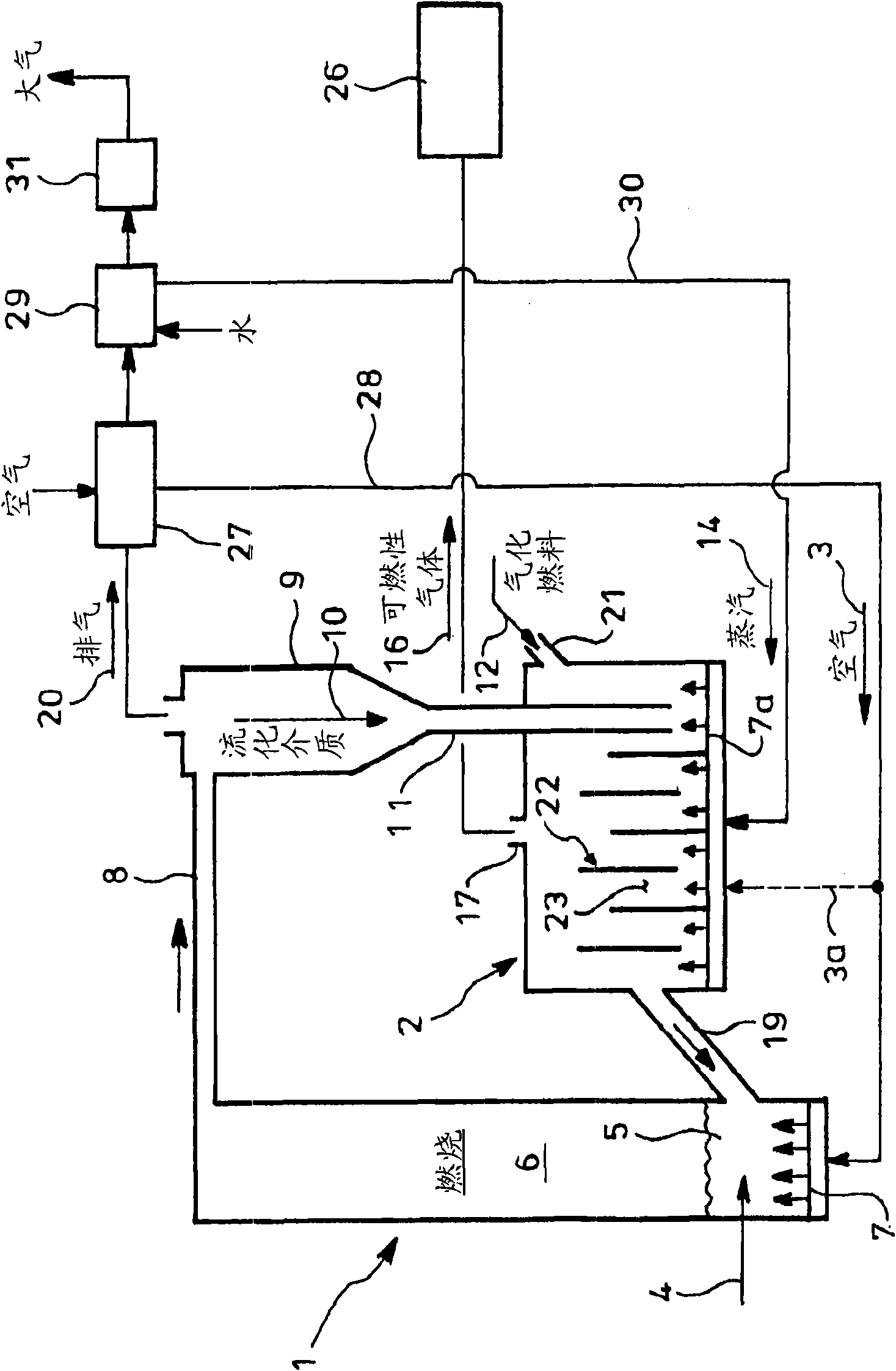

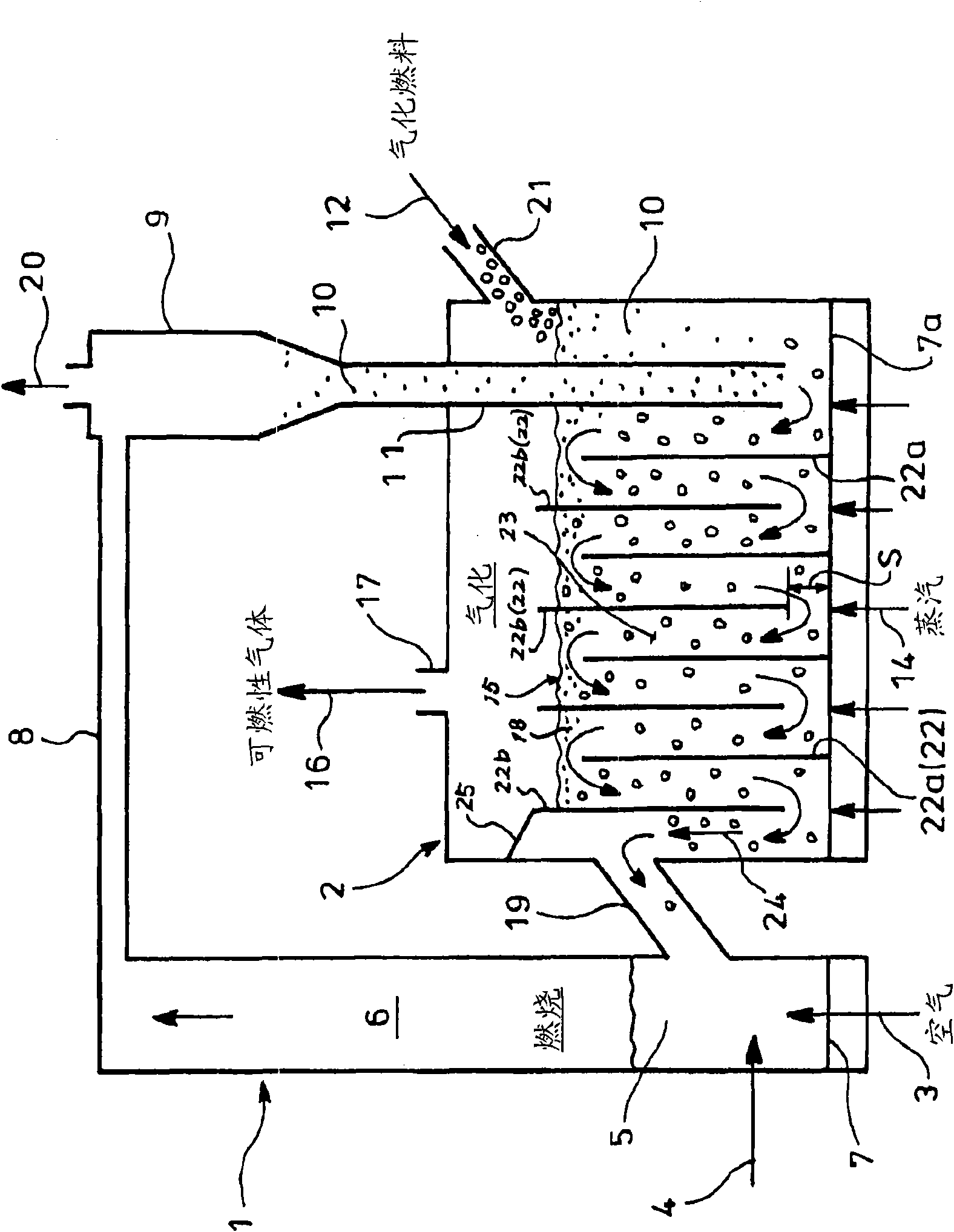

[0061] Embodiments of the present invention will be described below with reference to the drawings.

[0062] figure 2 , image 3 shown in figure 1 In the gasification furnace 2 shown, especially when the fuel with high fuel ratio is supplied, the gasification rate of the combustible solid components with large specific gravity can be improved, so for the figure and figure 1 For the same parts, descriptions of the same symbols are omitted, and only the characteristic parts of the present invention will be described in detail.

[0063] Such as figure 2 , image 3 As shown, the medium downflow pipe 11 for introducing the fluidized medium 10 separated by the aforementioned medium separation device 9 into the gasifier 2 and the fuel supply port 21 for introducing the gasification fuel 12 into the gasifier 2 are arranged in the aforementioned gasifier 2 inner side ( figure 2 , image 3 on the right side of the gasification furnace 2), and the solid content supply port 19 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com