Transmission system for grate cooler, transmission structure and grate cooler

A transmission system, grate cooler technology, applied in lighting and heating equipment, processing discharged materials, furnaces, etc., can solve the problems of poor operation reliability, difficult maintenance, and tedious installation, and achieve high reliability, simple maintenance, and high reliability. The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

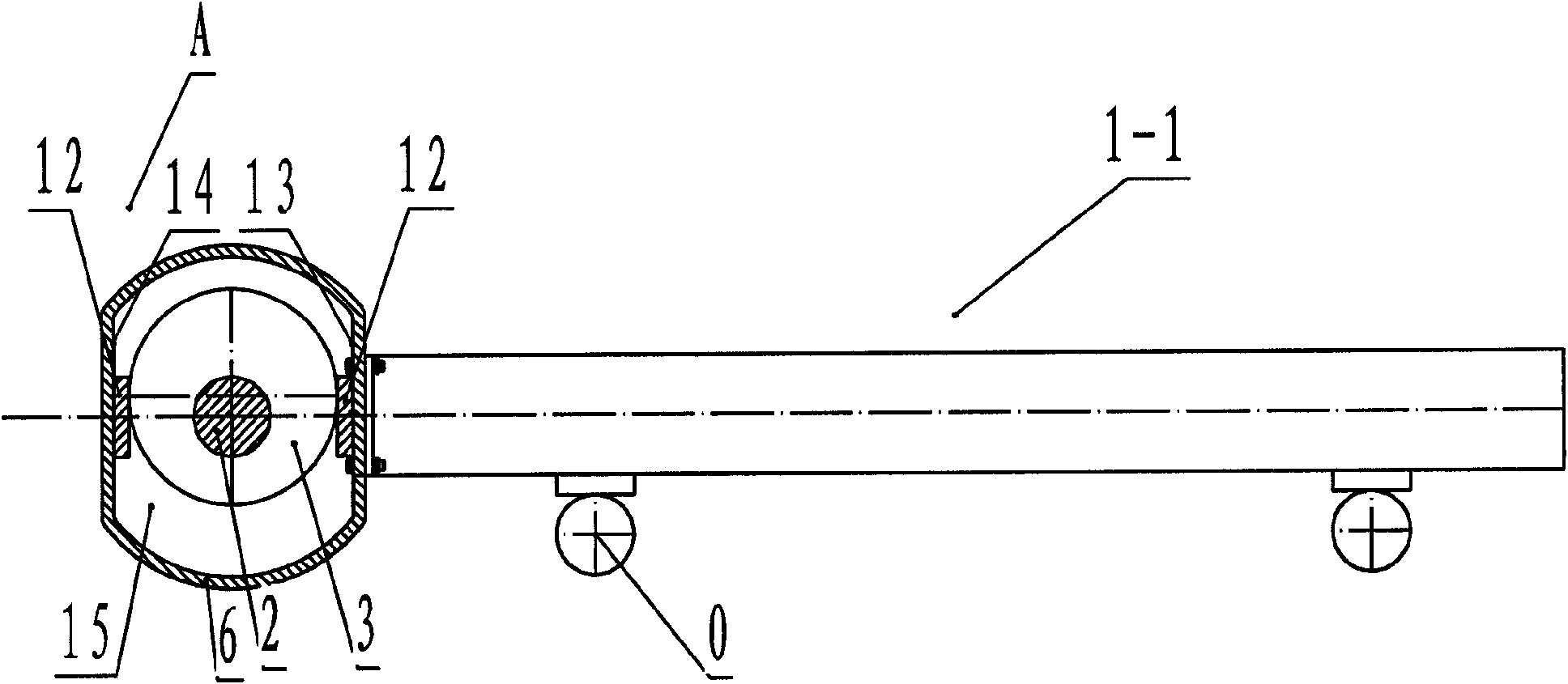

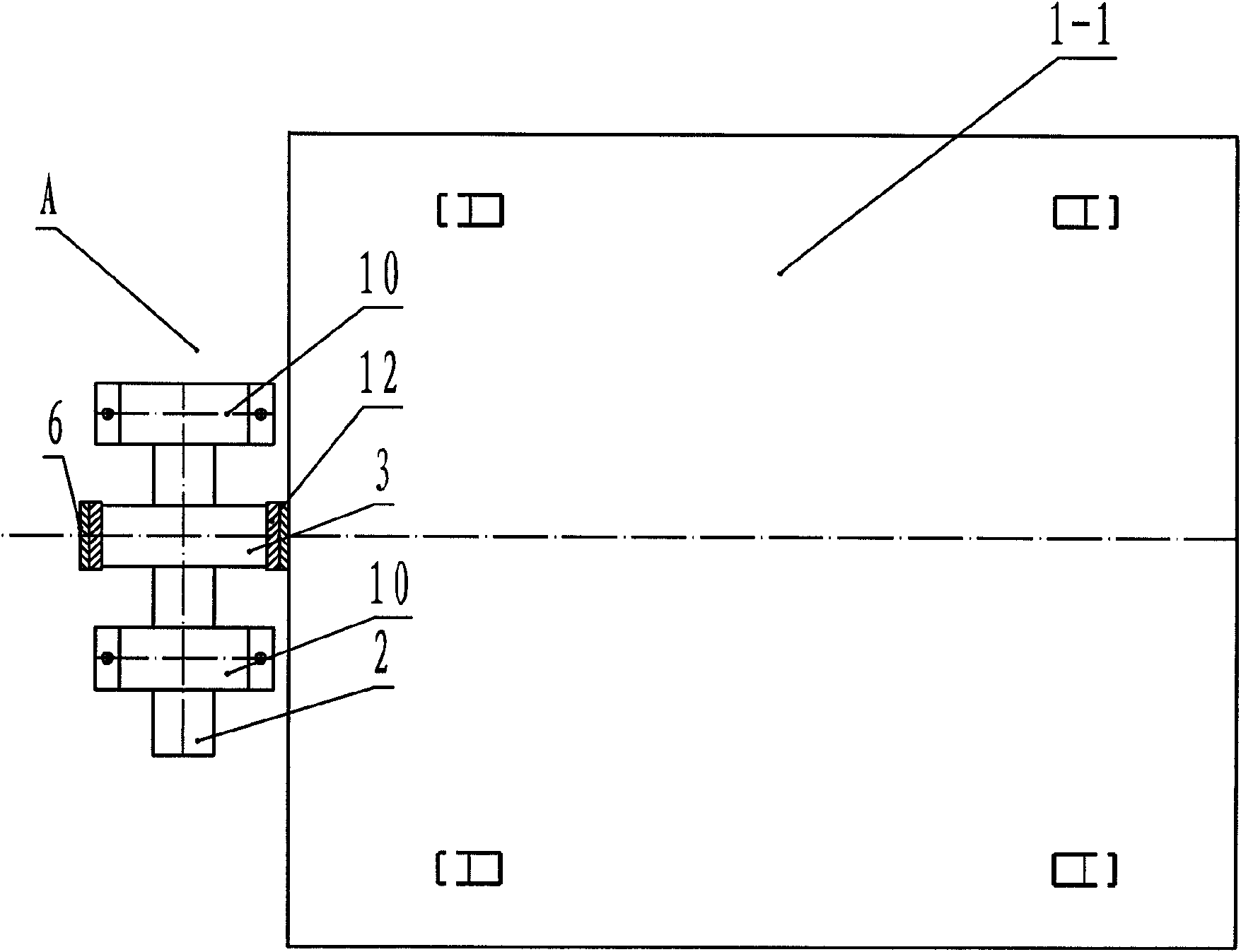

[0048] Such as figure 1 with figure 2 As shown, it is a structural schematic diagram of the first embodiment of the transmission system of the grate cooler of the present invention connected with the mobile trolley. The transmission system A is set in the middle of the rear end of the mobile trolley 1-1 (assuming that the material conveying direction is to the right in the figure, no special instructions, the same below), driven by the power system, it drives the mobile trolley 1-1 on the supporting wheel 0 for horizontal reciprocating motion, thereby driving the grate bed set on the moving trolley for horizontal reciprocating motion to cool and transfer hot clinker. The transmission system A includes an eccentric shaft 2 arranged laterally along the material conveying direction, and a cylindrical eccentric wheel 3 adapted to the eccentric shaft 2 (the eccentric shaft 2 and the eccentric wheel 3 may also be integrally structured, the same below ), two bearing housings 10 an...

Embodiment 2

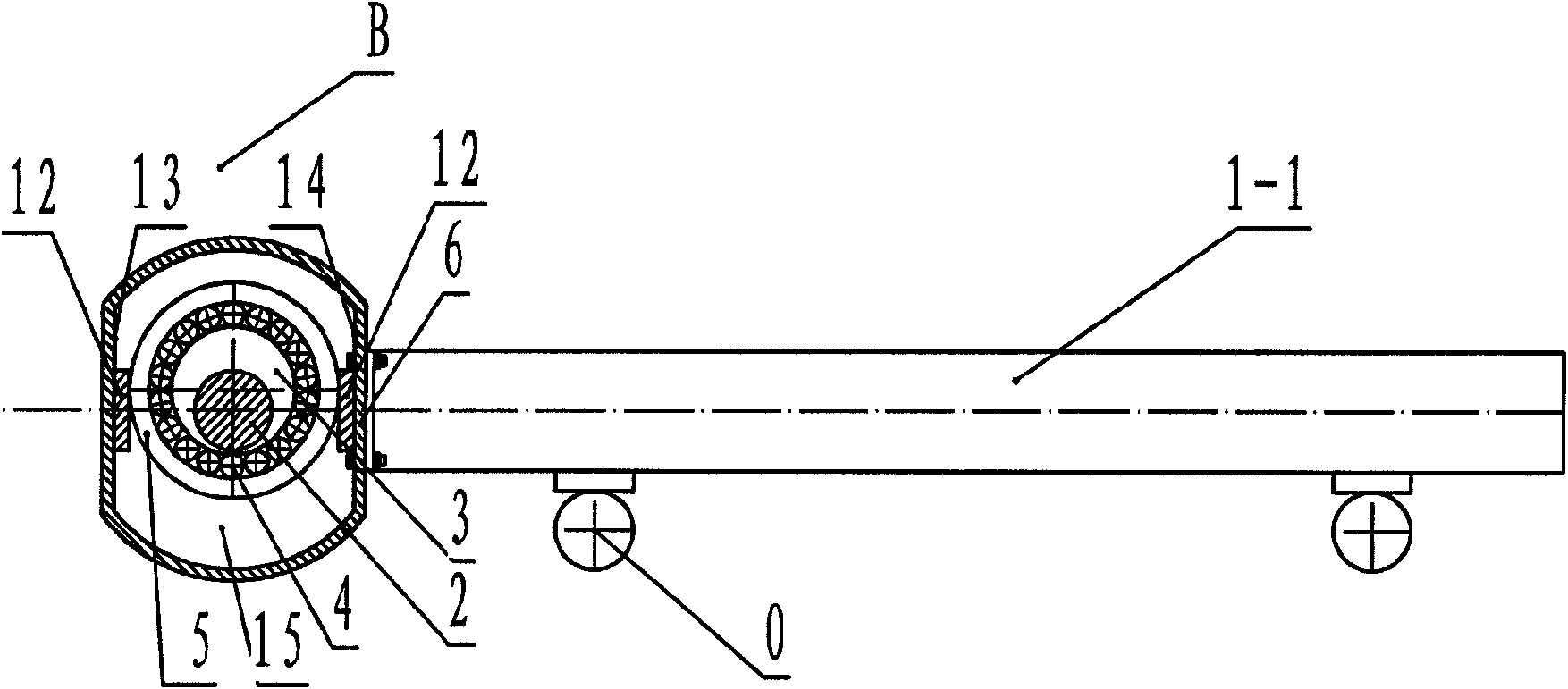

[0051] Such as image 3 As shown, it is a structural schematic diagram of the second embodiment of the grate cooler of the present invention connected to the mobile trolley. The transmission system B is arranged in the middle part of the front end of the mobile trolley 1-1 (in this embodiment, the material transmission direction is to the left in the figure), the difference between the transmission system B and the transmission system A is that the transmission system B also includes a bearing 4 and an outer wheel 5 , the outer wheel 5 is sleeved on the outer periphery of the eccentric wheel 3 through the bearing 4, the outer peripheral surface of the outer wheel 5 is a cylindrical surface (certainly also can be a drum-shaped surface), and the eccentric wheel 3 is placed on the front and rear inner surfaces 13 together with the bearing 4 and the outer wheel 5. 14 constitutes the accommodation space 15, and the front and rear inner surfaces 13, 14 are respectively fixed with fl...

Embodiment 3

[0054] Such as Figure 4 As shown, it is a schematic structural view of the third embodiment of the present invention connected to the mobile trolley (in this embodiment, the material conveying direction is to the left in the figure). The transmission system C is set between the mobile trolley 1-1 and the mobile trolley 1-2. Driven by the power system, it simultaneously drives the mobile trolley 1-1 and the mobile trolley 1-2 to perform horizontal reciprocating motion on the supporting wheel 0, thereby Drive the grate bed set on the moving trolley to do horizontal reciprocating motion to cool and transfer hot clinker. The difference between the transmission system C and the transmission system B is that: while the rear end face of the hollow cylinder 6 is fixedly connected to the front end of the mobile trolley 1-1, the front end surface of the hollow cylinder 6 is fixedly connected to the rear end of the mobile trolley 1-2, The transmission system C pushes a certain mobile t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com