High-level vertical lift park

A vertical lifting and parking garage technology, applied in the field of parking garages, can solve the problems of unreasonable anti-falling devices and long time, and achieve the effects of saving land area, convenient maintenance and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

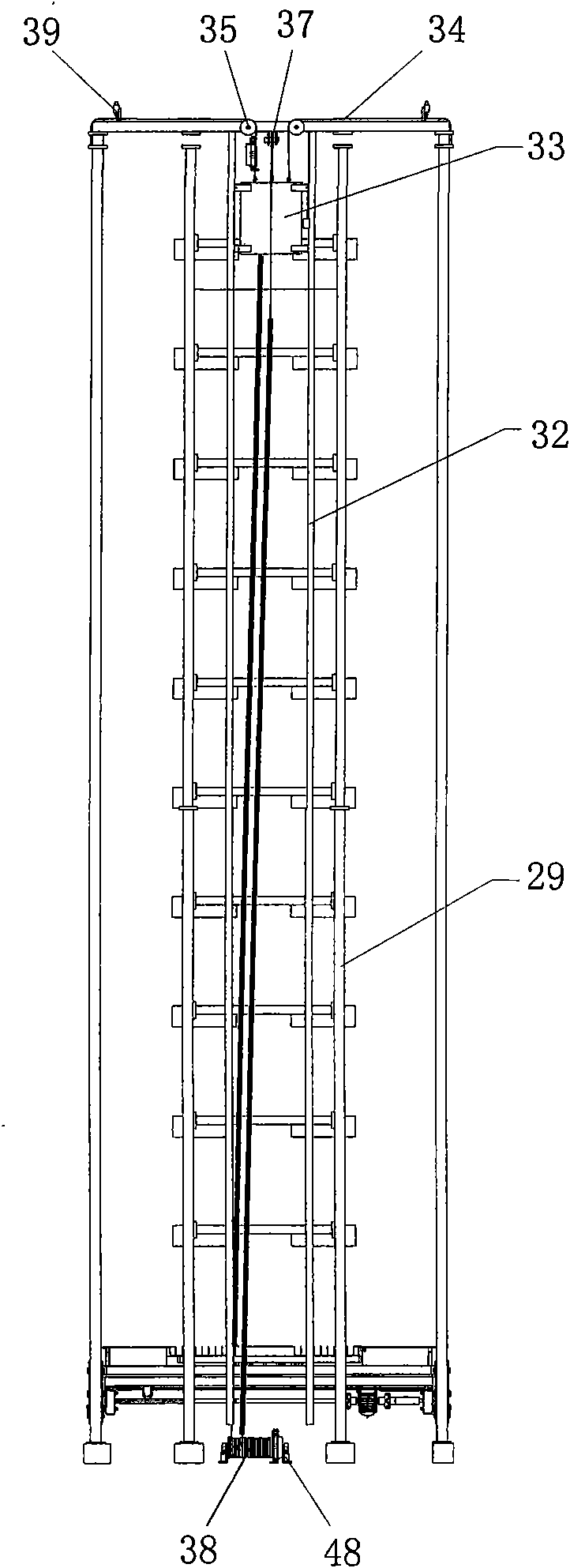

[0033] Please refer to the attached figure 1 , 2 , 3, on the inner side of the four columns 1, there are respectively fixed spur racks 2, gears on the H-type lifting platform mesh with the spur racks 2, and the H-type lifting platform is driven by the motor and sprocket wheel on the H-type lifting platform. The lifting platform moves up and down along the four uprights 1, and in the middle of the left and right two uprights of the four uprights 1, there are respectively two car rack uprights (not shown in the figure), along which the car rack uprights are arranged from bottom to top. Multi-layer car rack 30, each layer of car rack 30 is fixed on the crosspiece of the car rack 30 column by a plurality of parallel and equidistant steel pipes (not shown in the figure), and the H-type lifting platform is placed on the left and right. Lift in the middle of the grid 30, park or get the car on the grid 30.

[0034] The H-type lifting platform is composed of two parallel beams 9 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com