Energy-consumption braking control module of three-phase asynchronous motor

A control module and energy-consumption braking technology, which is applied in the field of stopping devices, can solve problems such as the difficulty of controlling the magnitude of DC current when using limited braking, and achieve the effects of being conducive to popularization and application, smooth braking, and high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

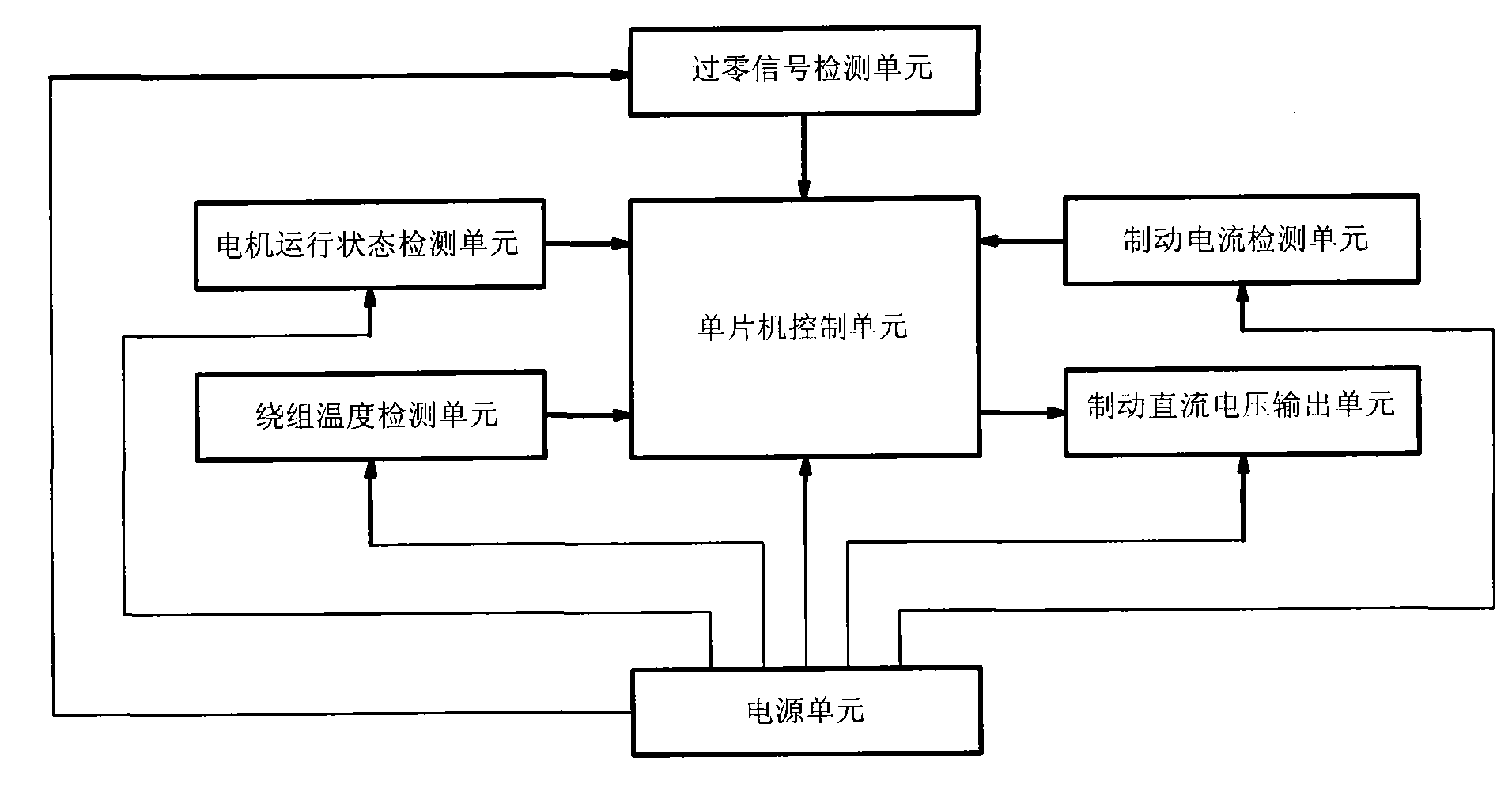

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

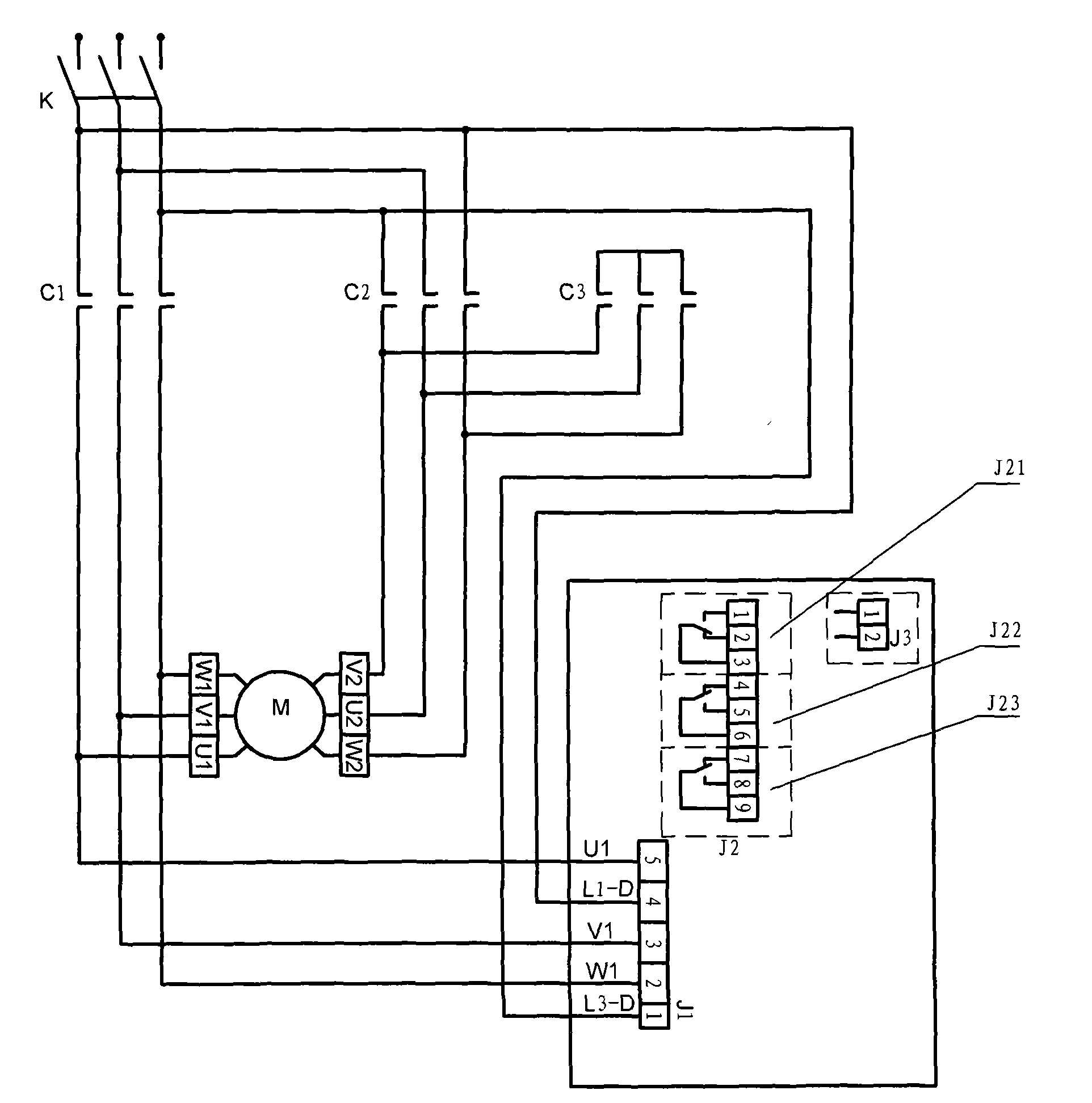

[0044] figure 1 The wiring diagram of the motor and the brake control module is given when the motor adopts the △ connection method.

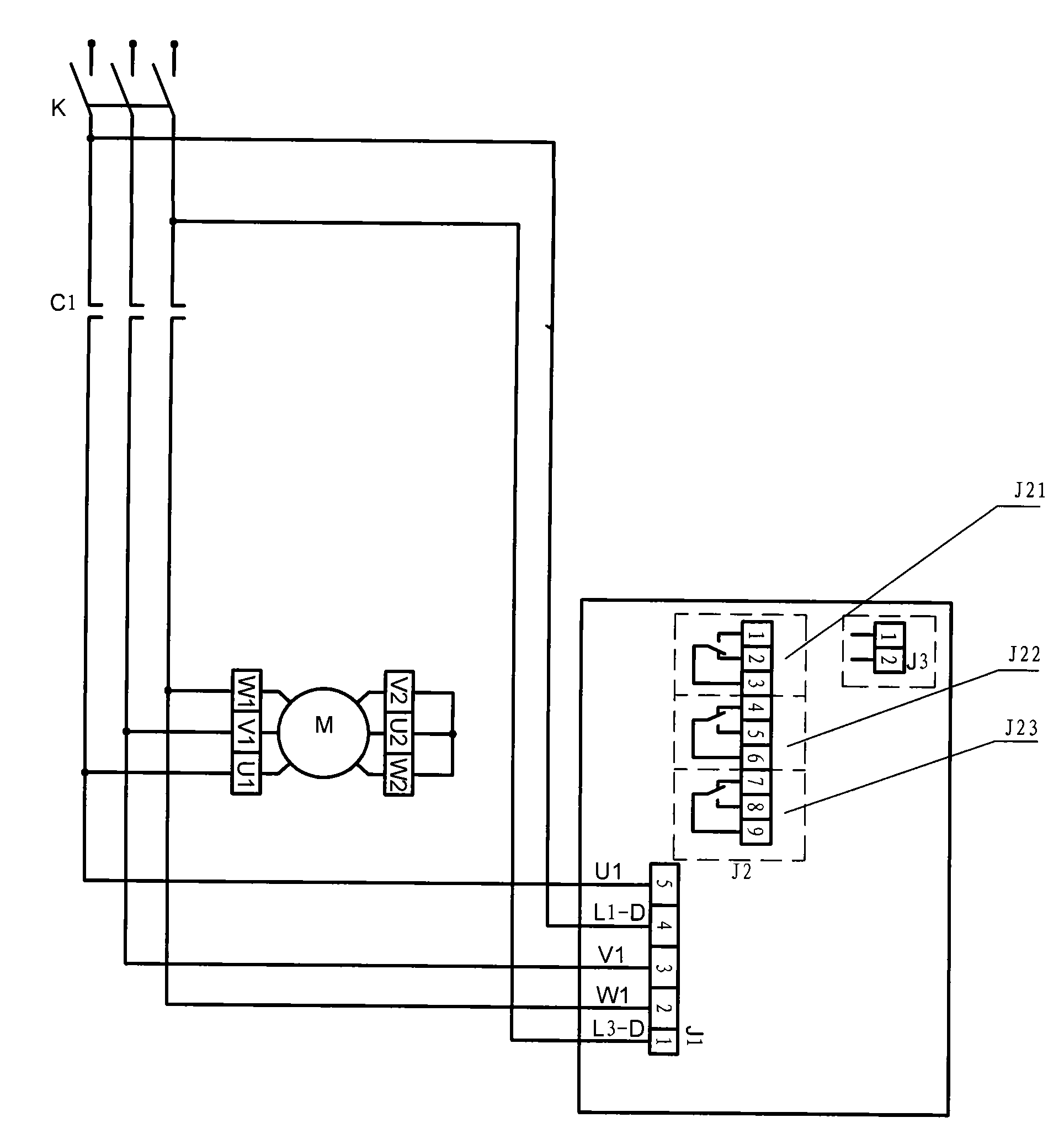

[0045] figure 2 The wiring diagram of the motor and the brake control module is given when the Y connection is used.

[0046] exist figure 1 , figure 2 Among them, there are three terminal blocks J1, J2 and J3 on the brake module.

[0047] Three-phase stator winding terminals U1, V1, W1 and line voltage terminals L1-D and L3-D are arranged on the terminal block of J1.

[0048] The three-phase stator winding terminals U1, V1, W1 are connected to the three-phase stator winding of the motor, among which the stator winding terminals V1 and W1 are used as the brake DC voltage output unit to connect to the two-phase stator winding terminals of the motor, and the stator winding wiring Terminal U1 is used as the input terminal of the running state signal detection unit.

[0049] The line voltage terminals L1-D and L3-D are respectively connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com